Unlocking Potential: The Future of rice mill plant Technology

In the heart of agrarian landscapes, where golden grains sway gently in the breeze, the humble rice mill stands as a vital hub of transformation. For centuries, this essential facility has played a crucial role in converting paddy into polished rice, the staple that nourishes billions worldwide. As global demands evolve and sustainability emerges as a pressing concern, the technology underpinning rice mill operations is on the brink of a revolution. From innovative milling processes to the integration of smart machinery, the future of rice mill plant technology promises not just enhanced efficiency, but also a more resilient agricultural ecosystem. This article explores the advancements that are setting the stage for a new era in rice production—one that harmonizes tradition with innovation, unlocking the full potential of this indispensable food source. Join us as we delve into the cutting-edge developments shaping the future of rice milling, highlighting the innovations that ensure we can meet the demands of tomorrow while nurturing our planet today.

Exploring Innovative Milling Techniques for Enhanced Efficiency

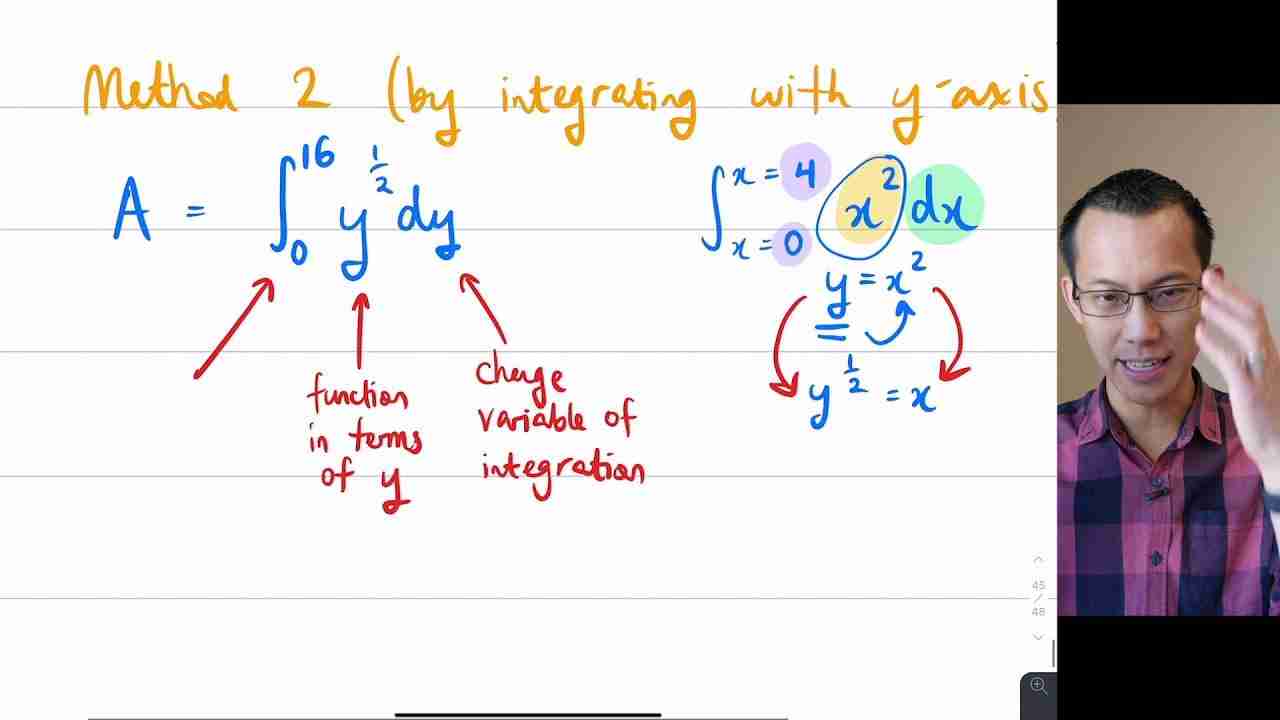

In the ever-evolving landscape of rice milling, innovative techniques have emerged as game-changers. Traditional milling methods often face challenges such as inefficiencies, high energy consumption, and subpar product quality. However, recent advancements offer exciting solutions that promise to boost productivity and improve output quality significantly. Modern rice mills are increasingly incorporating automation, which streamlines the processing steps and reduces the risk of human error. The integration of smart technology not only supports real-time monitoring of operational parameters but also allows for predictive maintenance, ensuring that equipment runs smoothly while minimizing downtime.

Additionally, the environmental impact of rice milling is a growing concern. By embracing sustainable practices, such as the use of energy-efficient machinery and waste recycling, rice mills can significantly reduce their carbon footprint. New milling technologies even prioritize water conservation and the utilization of renewable energy sources, making the entire production process eco-friendlier. Below is a comparison of traditional versus innovative milling techniques:

| Aspect | Traditional Milling | Innovative Milling |

|---|---|---|

| Efficiency | 40-50% yield | 70-80% yield |

| Energy Consumption | High | Reduced |

| Product Quality | Variable | Consistent |

| Environmental Impact | Higher | Lower |

This transformation is not just about upgrading equipment; it is a holistic approach that encourages mill operators to rethink operational strategies, workforce training, and customer engagement. By capitalizing on these advances, rice milling plants can secure a competitive edge while also contributing to a more sustainable future.

Integrating Automation and Smart Technology in Rice Processing Facilities

As the demand for efficiency and quality in rice production continues to rise, the integration of automation and smart technology becomes essential in modern processing facilities. By incorporating advanced systems such as automated milling machines, AI-driven quality control, and sensor-based monitoring, rice mills can significantly enhance their operational capabilities. The adoption of Internet of Things (IoT) technology allows for real-time data collection and analysis, providing mill operators with insights into production processes that were previously inaccessible. This connectivity not only streamlines workflows but also reduces the risk of human error, ultimately resulting in higher-quality end products.

Additionally, the implementation of an automated inventory management system can revolutionize supply chain operations. Facilities can track stock levels, monitor incoming shipments, and predict demand with remarkable accuracy. These innovations lead to better resource allocation and reduced waste, allowing businesses to improve their profitability. Consider the potential benefits listed below from such integrations:

- Increased Efficiency: Automation reduces processing time and labor costs.

- Enhanced Quality Control: Continuous monitoring ensures consistent product quality.

- Improved Traceability: Advanced tracking capabilities allow for better compliance with food safety regulations.

- Energy Savings: Smart technologies optimize energy consumption in processing.

| Feature | Impact |

|---|---|

| Automated Milling Machines | Increased output and reduced labor costs |

| AI-Driven Quality Control | Improved product consistency and marketability |

| IoT-Sensor Technology | Real-time monitoring for operational improvements |

| Automated Inventory Management | Optimized stock levels and reduced waste |

Sustainable Practices: Reducing Environmental Impact While Maximizing Yields

In the quest for agricultural advancement, modern rice mill technologies are innovatively designed to lower environmental impact while still enhancing production efficiency. By integrating renewable energy sources such as solar and wind, these facilities can operate using clean power, minimizing their carbon footprint. Moreover, the adoption of water-saving technologies not only conserves this precious resource but also ensures that rice production is sustainable in areas facing water scarcity. The implementation of systems that recycle water and utilize treated wastewater is becoming increasingly common among forward-thinking rice mill plants.

In terms of waste management, many facilities are now applying circular economy principles to repurpose by-products generated during the milling process. This includes turning husks and bran into animal feed or biofuel, which not only reduces waste but also contributes to additional revenue streams for farmers and mill operators. The following table showcases some promising sustainable practices:

| Practice | Benefits |

|---|---|

| Energy Efficiency Upgrades | Lower operational costs; reduced emissions |

| Precision Agriculture | Maximized yields; minimized resource use |

| Organic Soil Amendments | Enhances soil health; increases biodiversity |

| Digital Monitoring Systems | Real-time data for informed decision-making |

By adopting these practices, rice mill plants not only position themselves at the forefront of agricultural innovation but also contribute to a sustainable future for the industry. The continuous improvement of milling processes leads to more efficient resource utilization and showcases the potential of technology to enhance both environmental stewardship and agricultural productivity.

Investing in Training and Development: Building a Skilled Workforce for Future Growth

Investing in a skilled workforce is more than just a strategy; it’s a commitment to innovation and excellence, particularly in the rapidly evolving landscape of rice mill plant technology. By fostering continuous education and specialized training, organizations can equip their employees with the essential skills needed to navigate and implement advanced milling techniques. This approach not only enhances productivity but also propels the industry forward by enabling workers to operate new machinery and systems efficiently. The focus should be on:

- Technical Training: Hands-on experience with state-of-the-art equipment.

- Safety Protocols: Reinforcing health and safety standards within the plant.

- Process Optimization: Understanding lean manufacturing principles to reduce waste.

- Leadership Development: Encouraging mentorship and management skills for career growth.

Furthermore, investment in employee development translates into increased retention rates and employee satisfaction, which are vital for sustaining growth in the rice milling sector. As technology evolves, businesses can implement structured training programs designed around emerging trends such as automation, AI integration, and data analysis. Enhancing workforce capabilities can not only streamline operations but also provide a competitive edge in a crowded marketplace. Below is a brief overview of key training areas crucial for future advancements:

| Training Area | Benefits |

|---|---|

| Automation Systems | Improved efficiency and reduced labor costs. |

| Quality Control Techniques | Enhanced product consistency and customer satisfaction. |

| Data Analytics | Informed decision-making for better resource allocation. |

| Sustainability Practices | Alignment with environmental regulations and social responsibility. |

In Retrospect

As we stand at the crossroads of agricultural innovation, the future of rice mill plant technology shines bright with promise. By unlocking the potential of these advancements, we are not only optimizing production efficiency but also fostering sustainability and ensuring food security for generations to come. The journey ahead involves embracing cutting-edge technologies, from automation to smart sensors, and reimagining traditional practices to harmonize with modern demands. As we continue to explore and invest in these transformative solutions, the rice milling industry is poised for a revitalization that benefits farmers, consumers, and the environment alike. Together, we can cultivate a future where rice mill plants are not merely facilities of production but vibrant hubs of innovation and resilience, ultimately nourishing communities around the globe.