In the ever-evolving landscape of agriculture and food production, the quest for efficiency remains paramount. As global populations surge and the demand for staple crops intensifies, the mechanisms behind these vital processes come under increasing scrutiny. Enter the 4 Ton rice mill plant—a transformative innovation poised to revolutionize the rice milling industry. This groundbreaking technology not only streamlines production but also enhances productivity and sustainability. From reducing labor costs to minimizing waste, the 4 Ton Rice Mill Plant embodies the future of rice processing, merging traditional practices with modern engineering. In this article, we will delve into the intricacies of this remarkable plant, exploring how it unlocks efficiency and sets a new standard for the agricultural sector. Join us as we uncover the potential of this revolutionary tool and its implications for farmers, consumers, and the global food supply chain.

Harnessing Modern Technology for Optimal Performance

In the quest for efficiency, modern technology serves as the backbone of the 4-ton rice mill plant, significantly enhancing productivity while ensuring quality. By integrating automated sorting systems, the plant can seamlessly manage grain quality and minimize waste. Advanced machinery equipped with AI-based monitoring allows operators to track performance metrics in real-time, optimizing every aspect of the milling process. Key components like automated feeding mechanisms and state-of-the-art polishing machines not only expedite production but also improve the finished product’s texture and taste.

Furthermore, embracing data analytics leads to insights that were previously unattainable. By analyzing historical processing data, mill operators can make informed decisions that proactively address maintenance needs, reducing downtime. Cloud-based solutions facilitate remote monitoring, allowing stakeholders to oversee operations from anywhere, enhancing flexibility and responsiveness. The synergy between technology and traditional milling practices sets the stage for an unparalleled performance, reaffirming the commitment to maximizing output and sustainability in rice milling.

Streamlining Operations to Maximize Output and Minimize Waste

In the quest for enhanced efficiency within the 4 ton rice mill plant, every step of the operation can be meticulously optimized. By implementing cutting-edge technology that automates various processes, operators can significantly reduce manual handling and streamline workflows. The integration of real-time monitoring systems further allows for precise management of resources, ensuring that both energy and raw materials are utilized to their fullest potential. Key strategies include:

- Utilizing automated milling machinery for consistent output

- Incorporating data analytics to predict maintenance needs

- Employing lean manufacturing techniques to eliminate bottlenecks

- Optimizing the supply chain for timely procurement

Moreover, assessing waste management practices is essential for minimizing losses. Implementing a circular system within the plant not only limits waste but also creates opportunities for new revenue streams through by-products such as rice husk and bran. By focusing on a holistic approach to production and considering both input and output, manufacturers can transition towards a more sustainable model. A simple overview of potential by-products generated in the milling process is outlined in the table below:

| By-Product | Potential Uses |

|---|---|

| Rice Husk | Biofuel, animal bedding, insulation |

| Rice Bran | Food additives, cooking oil, cosmetics |

| Broken Rice | Animal feed, brewing, industrial starch |

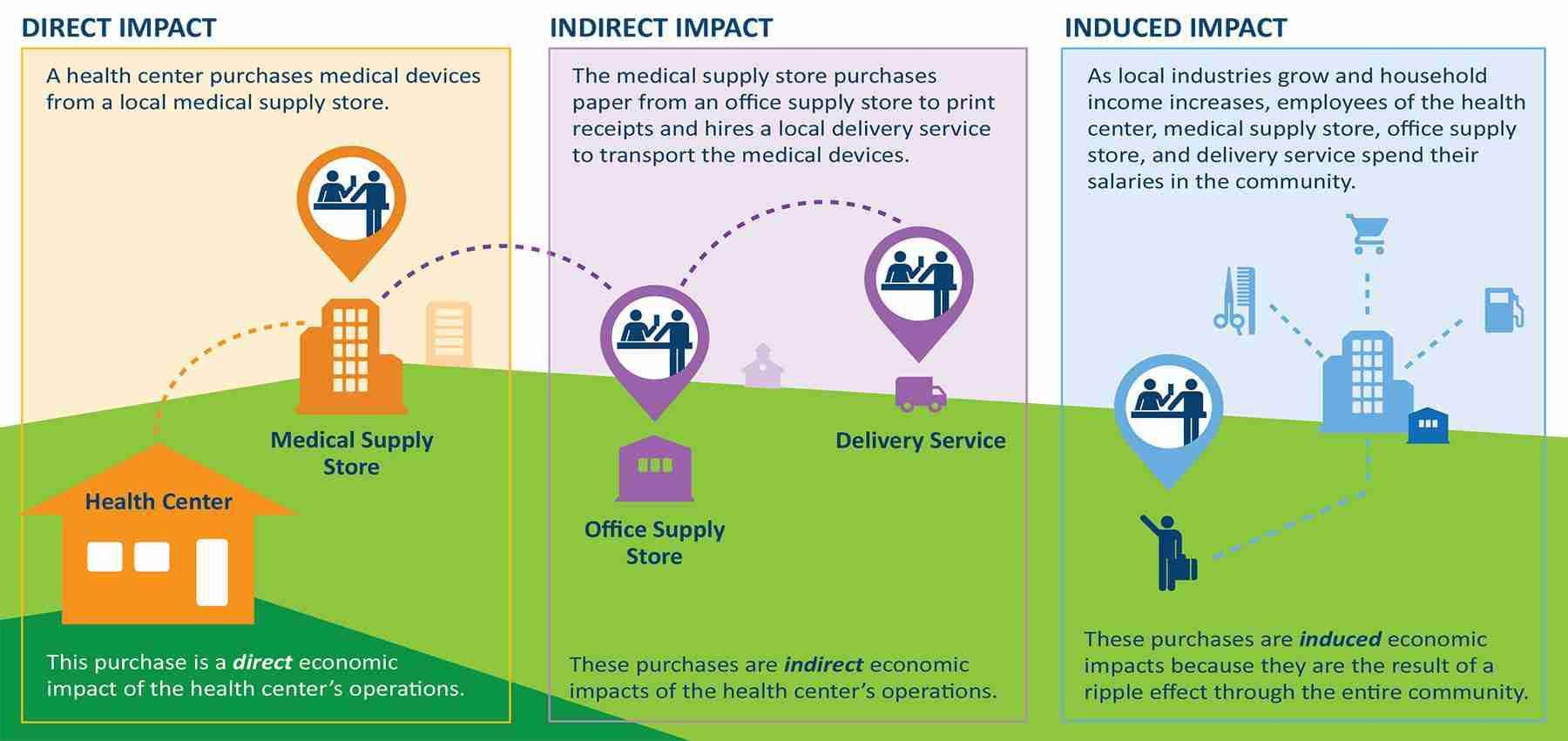

Understanding the Economic Impact of a 4 Ton Rice Mill Plant

The establishment of a 4 ton rice mill plant holds significant economic potential, particularly in regions where rice production is a staple of local agriculture. By implementing cutting-edge milling technology, these plants can enhance the quality and yield of processed rice, leading to increased profitability for farmers and mill operators alike. The following factors illustrate the broad economic impact:

- Job Creation: A rice mill plant creates various job opportunities, ranging from skilled positions in machinery operation to unskilled roles in production and maintenance.

- Increased Income: Higher efficiency in processing leads to better prices for rice, resulting in improved incomes for local farmers.

- Supply Chain Optimization: With local milling, farmers reduce transportation costs and waste, effectively increasing their profit margins.

Moreover, the introduction of a modern 4 ton rice mill can stimulate the local economy by encouraging investment and fostering related industries, such as packaging, distribution, and marketing. It can also enhance food security by ensuring that high-quality rice is readily available to the community. Below is a simple table illustrating the impacts:

| Impact Type | Description |

|---|---|

| Employment Generation | Creation of xx direct and indirect jobs. |

| Income Increases | Average income boost of xx% for farmers. |

| Local Investment | Stimulates additional investments of $xx million. |

Through these avenues, a 4 ton rice mill plant not only transforms agricultural practices but also contributes to sustainable economic development in the community, making it a crucial asset that outweighs initial investment costs.

Sustainability Practices for a Greener Rice Milling Future

As the demand for rice continues to rise, the need for sustainable practices in rice milling becomes increasingly apparent. Innovative milling plants are adopting advanced technologies and methods that minimize waste and enhance resource efficiency. By integrating energy-efficient machinery and renewable energy sources, rice mills can contribute significantly to reducing their carbon footprint. For instance, utilizing biomass from rice husks not only generates energy but also reduces dependence on non-renewable fuel sources. This closed-loop system leads to a more sustainable production cycle that benefits both the environment and the mill’s profitability.

Moreover, incorporating water conservation techniques is essential for a greener future in rice milling. Implementing recirculating water systems or rainwater harvesting can dramatically decrease water usage during the milling process. Additionally, engaging local communities in sustainable farming practices and sourcing rice from organic growers enhances the quality of the raw material while promoting biodiversity. Here’s a brief overview of potential sustainable practices:

| Practice | Benefit |

|---|---|

| Energy Efficiency | Reduces energy consumption and costs. |

| Renewable Energy | Minimizes reliance on fossil fuels. |

| Water Conservation | Decreases overall water usage. |

| Waste Utilization | Turns by-products into valuable resources. |

Future Outlook

the 4 Ton Rice Mill Plant stands as a beacon of innovation in the agricultural machinery landscape. Its ability to enhance productivity and streamline processes creates a ripple effect, benefiting farmers, millers, and consumers alike. By embracing technology and efficiency, we unlock not just the potential of rice milling, but also pave the way for a sustainable future in food production. As we move forward, it is essential to continually explore and invest in such advancements to ensure the growth and resilience of the agricultural sector. The revolution is just beginning—let us embrace it and cultivate a world where efficiency flourishes alongside quality.