Turning Grains into Gold: The 2 Ton rice mill plant Project

In the heart of our agricultural landscapes, where fields of golden grains sway rhythmically under the sun, lies a transformative endeavor aimed at redefining the way we perceive and utilize our bountiful harvests. The 2 Ton Rice Mill Plant Project emerges as a beacon of innovation and sustainability, illuminating the path toward maximizing the value of one of the world’s most vital staple foods: rice. This initiative not only promises to enhance the efficiency of processing rice but also stands as a testament to the ingenuity that drives the agricultural sector forward. As we delve into the mechanics of this project, we explore how turning grains into gold is not merely a metaphor for economic gain; it embodies a holistic approach to empowering communities, fostering food security, and promoting a more resilient future for all. Join us as we unravel the intricacies of this ambitious project and the potential it holds for transforming lives one grain at a time.

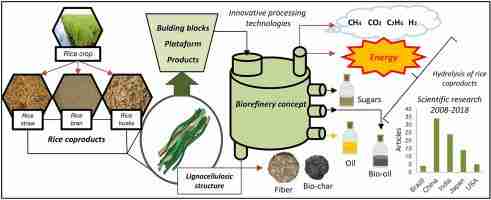

Innovative Techniques for Rice Processing and Value Addition

Recent advancements in technology have transformed the landscape of rice processing, enhancing efficiency and output while ensuring better quality. The integration of automated systems and artificial intelligence has revolutionized traditional milling methods. Mills can now utilize color sorting machines to eliminate defective grains, guaranteeing a uniform product. Additionally, parboiling systems have gained popularity, allowing farmers to partially cook rice prior to milling. This technique not only enhances nutritional value but also improves shelf life and cooking quality, making it a win-win for both producers and consumers.

Furthermore, the value addition process has seen innovative strategies that cater to evolving market demands. The production of rice bran oil and rice flour, for example, offers diversified income streams. Implementing post-harvest processing units can facilitate the extraction of nutritious by-products that draw consumer interest. These innovations underscore the potential of a 2-ton rice mill plant, enabling small and medium enterprises to maximize profitability while contributing to food security. The demand for organic and specialty rice varieties, supported by efficient processing techniques, positions this project as a pioneering venture in the agricultural sector.

Sustainable Practices in Rice Milling for Economic Growth

Embracing environmentally-friendly techniques in rice milling not only enhances productivity but also lays the foundation for sustainable economic development. By implementing practices such as energy-efficient machinery, mills can significantly reduce their carbon footprint while lowering operational costs. Additionally, utilizing solar power or biomass energy can help facilities become self-sufficient, thus promoting local sources of energy. The integration of sustainable water management systems ensures minimal waste, helping to preserve this precious resource while improving overall production efficiency.

Moreover, adopting a holistic approach by involving local communities in the milling process can generate further economic benefits. This includes providing training programs to maintain high standards of quality control and sustainability. When rice is milled using these methods, it can lead to higher-quality products that command better prices in the market. Creating partnerships with organizations focusing on sustainable agriculture not only facilitates access to innovative technologies but also opens doors to new markets while fostering community well-being.

Essential Components and Technology for a Cutting-Edge rice mill plant

To establish a modern rice mill plant that maximizes efficiency and product quality, several key components and advanced technologies are indispensable. Central to the operation is the paddy cleaner, designed to remove impurities like stones and husks, ensuring only the best quality rice grains proceed through the milling process. Following this, the installation of a husker machine helps remove the outer husk without damaging the rice grain inside, maintaining its integrity. Other essential components include destoners, which filter out any remaining stones, and whitening machines, which polish the rice grains to enhance their appearance and marketability.

Incorporating state-of-the-art technology directly impacts the productivity and efficiency of the rice mill. For instance, automated control systems allow operators to monitor and adjust settings in real-time, optimizing every aspect of the milling process. Additionally, dust collection systems are vital for maintaining a clean working environment and adhering to safety regulations. Implementing energy-efficient motors not only reduces operational costs but also contributes to sustainability efforts. A summary of these essential components is outlined in the table below:

| Component | Function |

|---|---|

| Paddy Cleaner | Removes impurities before milling. |

| Husker Machine | Extracts husk without damaging grain. |

| Whitening Machine | Polishes rice for better quality. |

| Automated Control Systems | Monitors and adjusts milling settings. |

| Energy-Efficient Motors | Reduces operational costs and enhances sustainability. |

Strategic Planning for Successful Implementation and Operation

To ensure the seamless execution of the 2 Ton rice mill plant Project, a carefully outlined strategy is essential. This involves meticulous planning that addresses several key factors crucial for operational success. Identifying target markets enables a focused approach to production, while an in-depth understanding of local supply chains ensures optimal sourcing of raw materials. Moreover, it is imperative to engage with stakeholders through regular communication to foster collaboration and address any potential challenges swiftly. Effective leadership will be necessary to navigate the project through various phases, keeping all teams aligned with the overarching goals.

Operational implementation should include structured timelines and defined milestones, ensuring that every phase of the project is executed efficiently. This can be supported by a robust framework for continuous assessment and improvement, allowing for adjustments based on real-time feedback. Key components of this framework may include:

- Resource Allocation: Assigning the right personnel and equipment to each stage of the process.

- Risk Management: Developing fallback plans to counter unforeseen issues.

- Training Programs: Ensuring staff is well-prepared to utilize the technology safely and effectively.

Additionally, implementing a monitoring system will be crucial for measuring progress against set objectives. A simple table for tracking these objectives could look like this:

| Objective | Target Date | Status |

|---|---|---|

| Complete Construction | MM/DD/YYYY | In Progress |

| Install Machinery | MM/DD/YYYY | Pending |

| Begin Operations | MM/DD/YYYY | Planned |

Adopting this structured approach not only heightens the likelihood of successful project implementation but also positions the rice mill plant for sustained operational excellence.

Key Takeaways

As we conclude our exploration of the transformative journey undertaken by the 2 Ton Rice Mill Plant Project, it becomes clear that innovation, sustainability, and the promise of economic upliftment can indeed turn grains into gold. This initiative not only highlights the potential of rice milling technology to enhance productivity and quality in grain processing but also demonstrates the far-reaching impact it can have on local communities. With a commitment to efficiency and responsible practices, the project lays the groundwork for a future where small-scale farmers can thrive, contributing to food security and economic resilience.

As we look ahead, it’s essential to recognize the invaluable role such projects play in redefining agricultural landscapes and fostering a more sustainable food system. By investing in modern methods and supporting local industry, we are not just converting rice into a commodity but setting the stage for prosperity that ripples through generations. The grains may be humble, but the gold they yield is measured in opportunity, empowerment, and hope for a better tomorrow. What remains to be seen is how the seeds of this initiative will nurture the fields of progress, and we are all invited to witness and support this unfolding narrative.