Transforming Grains: The Essential Guide to Rice Milling Units

In the heart of agriculture, where the journey from field to table begins, the humble grain of rice stands as a vital pillar of sustenance for billions around the globe. Yet, the journey of rice is far from straightforward; it undergoes a meticulous transformation that is crucial to its appeal and edibility. Enter the rice milling unit—an intricate system designed to refine paddy into the pristine grains that fill our bowls and fuel our lives. This essential guide delves into the world of rice milling units, unveiling the technology and processes that convert raw paddy into the polished staple we often take for granted. From understanding the mechanics of milling to exploring the impact of technology on efficiency and quality, we will equip you with the knowledge needed to appreciate the complexities and innovations behind one of humanity’s oldest cultivated crops. Join us as we embark on a journey to demystify the rice milling process and discover how these units are transforming grains for a sustainable future.

Understanding the Rice Milling Process and Its Importance

The rice milling process is a delicate and essential journey that transforms harvested paddy into the polished grains that grace our tables. This intricate procedure involves several key stages: hulling to remove the outer husk, followed by milling, where the bran layer is eliminated to yield the white rice. Each step requires precise machinery and skilled operators, ensuring that the final product not only meets quality standards but also retains nutritional value. The effectiveness of these processes significantly impacts both the yield and quality of the rice, which is a staple food in numerous cultures worldwide.

Understanding the nuances of rice milling is vital for producers, as it directly influences market competitiveness and food security. Factors such as moisture content and machine calibration play crucial roles in achieving optimal results. Additionally, technological advancements have revolutionized milling units, introducing energy-efficient methods and reducing waste. To illustrate the importance of traditional versus modern milling techniques, consider the following table comparing their efficiency and output:

| Feature | Traditional Milling | Modern Milling |

|---|---|---|

| Processing Time | Longer | Faster |

| Efficiency | Lower | Higher |

| Energy Consumption | More | Less |

| Quality of Output | Variable | Consistent |

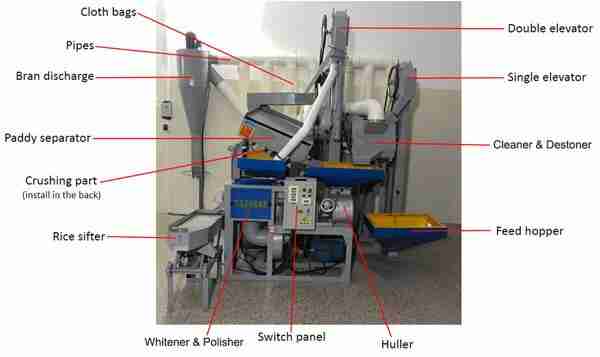

Key Components and Technologies in Rice Milling Units

The heart of any rice milling unit lies in its sophisticated machinery and the intricate processes that work in concert to transform paddy into polished rice. At the forefront are huskers, which remove the outer husk of the paddy, followed by whitener machines that polish the rice grains by removing bran layers. These components are essential as they dictate both the yield and quality of the final product. Additionally, destoners play a crucial role by separating stones and other impurities through advanced air suction systems, ensuring that the rice is clean and ready for processing. Alongside these machines, escarifiers and color sorters further enhance product quality by removing discolored or defective grains, providing consumers with a premium product.

Modern rice milling units also incorporate automation technologies, such as sensor-based sorting systems and data analytics software, to enhance efficiency and precision. The integration of variable frequency drives (VFDs) allows for better control of motor speeds, optimizing energy consumption and reducing costs. As environmental considerations grow more pressing, the inclusion of water recycling systems has proven vital in conserving resources during milling operations. When examining the economics of rice milling, the choice of technology can significantly impact productivity and waste management. An efficient layout of the milling flow, coupled with the right machinery, can lead to lower operational costs and increased profitability for rice mill operators.

| Component | Function | Benefits |

|---|---|---|

| Huskers | Remove outer husk | Increases yield |

| Whitener | Polish rice grains | Improves appearance |

| Destoners | Remove impurities | Ensures cleanliness |

| Color Sorters | Identify defective grains | Enhances quality |

Selecting the Right Rice Milling Equipment for Your Needs

When it comes to choosing rice milling equipment, understanding the specific requirements of your operation is vital. Factors such as the volume of rice you intend to process daily, desired grain quality, and the level of automation can significantly influence your selection. Consider the following key aspects:

- Capacity: Evaluate your production needs. Are you a small-scale miller or a large industrial operation?

- Type of Rice: Different varieties may require specialized milling techniques.

- Technical Features: Look for innovations like digital controls and automatic adjustments for efficiency.

- Maintenance: Consider equipment that ensures easy cleaning and upkeep to minimize downtime.

Moreover, it’s essential to investigate the energy efficiency of the machinery. With rising energy costs, opting for equipment that maximizes output while minimizing energy consumption can save you substantial amounts in the long run. To gain a clearer understanding of your options, here’s a helpful comparison of common milling machines:

| Equipment Type | Capacity (kg/h) | Energy Consumption (kW) | Typical Use |

|---|---|---|---|

| Stone Mill | 50-300 | 5-10 | Traditional milling |

| Hammer Mill | 100-800 | 10-25 | Versatile grain processing |

| Modern Rice Mill | 500-2000 | 20-50 | Large-scale production |

| Parabolic Mill | 200-1000 | 15-30 | High-quality rice |

Ultimately, making an informed selection requires a careful balance of features, costs, and support services. Collaborating with manufacturers or suppliers who understand your local market can yield valuable insights, ensuring that you invest in equipment that not only meets your current needs but also adapts to future demands.

Best Practices for Maintenance and Efficiency in Rice Milling

Ensuring optimal performance in rice milling units requires a systematic approach to maintenance and efficiency. One crucial practice is to regularly inspect and clean machinery components. Dust, broken grains, and debris can accumulate and lead to operational slowdowns or even malfunctions. Schedule routine maintenance checks and keep a log for each piece of equipment, which not only helps in identifying recurring issues but also allows for timely interventions. Additionally, focus on training staff to recognize early warning signs of trouble, ensuring everyone is equipped to maintain machinery effectively.

Another vital aspect of improving milling efficiency is optimizing the milling process itself. This can be achieved by implementing the following strategies:

- Utilizing energy-efficient machinery to reduce electricity costs.

- Adjusting the moisture level of the rice being processed to ensure optimal milling quality.

- Regularly calibrating machines to maintain the desired output quality.

- Developing a quality control system to monitor varietal differences in the rice being milled.

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Inspect belts and pulleys | Weekly | Prevent unexpected breakdowns |

| Clean grain hoppers | Biweekly | Ensure smooth flow of raw materials |

| Check lubrication levels | Monthly | Reduce wear and tear on machinery |

| Evaluate output quality | Daily | Maintain product standards |

Key Takeaways

As we draw the curtain on our exploration of rice milling units and the transformative journey of grains, it’s clear that these industrious machines play a pivotal role in bridging the gap between the fields and our tables. With each turn of the milling wheel, grains are not only polished but transformed into culinary essentials that nourish and delight the world.

Whether you’re a farmer looking to optimize your production, an entrepreneur seeking investment opportunities, or a culinary enthusiast eager to understand the origins of your ingredients, the insights gathered here serve as a foundation for embracing the art and science of rice milling.

As the global demand for quality rice continues to rise, so too does the opportunity for innovation within this vital sector. By investing in modern techniques and sustainable practices, we can ensure that the story of rice milling evolves alongside our ever-changing food landscape.

In the endless cycle of cultivation and consumption, may we always remember the journey of the grains that grace our plates. Thank you for joining us on this odyssey of transformation—together, we can elevate not just rice, but the very essence of what it means to grow, mill, and enjoy our food.