Transforming Grain to Gold: The Rise of Automatic Rice Mills

In an age where innovation meets tradition, the hum of machinery has begun to harmonize with the timeless rituals of agriculture. Rice, often referred to as the “golden grain,” has been a staple food for billions, sustaining cultures and economies for centuries. Yet, as the demand for efficiency and quality surges in an ever-evolving global marketplace, the rise of automatic rice mills marks a transformative chapter in the story of this revered commodity. These advanced processing units not only promise to enhance productivity but also aim to preserve the essence of one of the world’s most vital crops. As we delve into the mechanics behind these modern marvels, we discover how they are revolutionizing the rice industry, empowering farmers, and, ultimately, turning grain into gold for communities across the globe. Join us on this journey through innovation and tradition, as we explore the impact, challenges, and future of automatic rice mills.

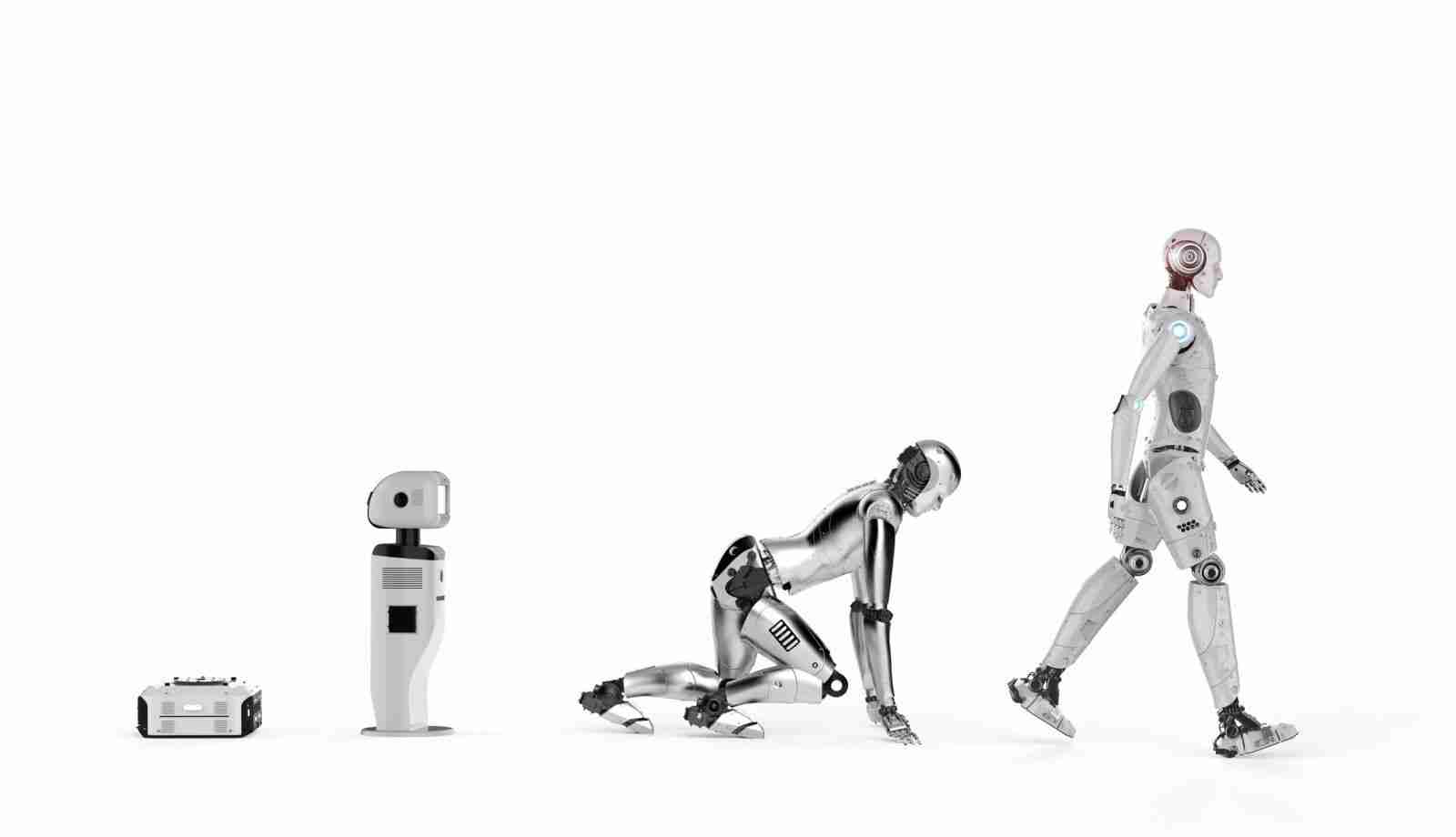

The Technological Evolution Behind Automatic Rice Mills

The journey of rice milling has undergone a remarkable transformation, driven by a series of remarkable technological advancements. In the past, rice milling was a labor-intensive process, often reliant on manual labor and simple machinery. However, the introduction of automatic rice mills has revolutionized this industry, enhancing efficiency and quality. These modern mills are equipped with innovative features such as auto-feeding mechanisms and precision milling technology, allowing for a consistent and uniform product every time. By integrating IoT (Internet of Things) technology, automatic rice mills now provide real-time monitoring and data analysis to optimize the milling process, ensuring minimal waste and maximum yield.

Furthermore, sustainability has become a focal point in the design of automatic rice mills. These mills often incorporate energy-efficient systems, such as solar-powered machinery and regenerative braking technology, significantly reducing their carbon footprint. The use of advanced materials in construction has also minimized wear and tear, extending the lifespan of these machines. Below is a simple comparison of traditional versus automatic rice milling systems, illustrating the significant benefits of technological evolution:

| Aspect | Traditional Rice Mills | Automatic Rice Mills |

|---|---|---|

| Labor Requirement | High | Low |

| Milling Efficiency | Variable | Consistent |

| Energy Consumption | Higher | Lower |

| Product Quality | Inconsistent | High |

Enhancing Efficiency and Productivity in Grain Processing

Recent advancements in automatic rice milling technology have ushered in a new era of operational efficiency, revolutionizing the way grains are processed. By integrating sophisticated machinery and intelligent automation, grain processors can now achieve unparalleled levels of productivity. Key benefits include:

- Reduced Labor Costs: With automation reducing the need for manual labor, companies can significantly decrease overhead expenses.

- Faster Processing Times: Automated systems operate at speeds that far exceed traditional methods, allowing for higher output in shorter time frames.

- Consistency and Quality: Precision technology ensures uniform processing, leading to better quality grains that meet stringent market standards.

- Data-Driven Decisions: Modern rice mills come equipped with sensors and software that track performance metrics in real-time, enabling operators to make informed decisions swiftly.

| Feature | Traditional Mills | Automatic Mills |

|---|---|---|

| Processing Speed | Slow | Fast |

| Labor Requirement | High | Low |

| Quality Control | Variable | Consistent |

| Operational Costs | High | Reduced |

The rise of automatic rice mills not only streamlines the processing workflow but also fosters sustainable practices within the agricultural sector. By minimizing waste and enhancing resource utilization, these advanced systems contribute to a greener environment. Furthermore, automation allows producers to swiftly adapt to market demands and consumer preferences, ensuring they remain competitive in an evolving landscape. This seamless blend of efficiency and sustainability represents the future of grain processing, transforming potential into tangible results.

Sustainable Practices: Balancing Profit and Environmental Impact

The evolution of automatic rice mills is not just a technical advancement but also a commitment to sustainable practices in agriculture. These mills are designed to optimize every grain processed, enhancing efficiency while minimizing waste. By implementing state-of-the-art technology, they reduce energy consumption and water usage, creating a ripple effect that extends from the production line to the environment. This shift is changing the conversation around profitability, highlighting that sustainability can coexist with competitive pricing and high-quality output. Automatic rice milling systems contribute to less spoilage and better utilization of raw materials, creating a substantial positive impact on local economies and ecosystems.

One of the standout features of modern rice mills is their ability to recycle by-products, turning what was once considered waste into valuable resources. This practice not only adds to the bottom line but also aligns with eco-friendly initiatives. By reprocessing husks and bran, these mills generate biofuel and animal feed, showcasing a model where profit does not come at the expense of the environment. Examples of benefits from these practices include:

- Reduced carbon footprint through energy-efficient operations.

- Enhanced soil health from returning organic materials to the land.

- Community empowerment via local job creation in sustainable operations.

To illustrate the effectiveness of these sustainable technologies, the following table compares traditional mills with automatic systems:

| Feature | Traditional Mills | Automatic Rice Mills |

|---|---|---|

| Energy Consumption | High | Low |

| Waste Generation | High | Minimal |

| Profitability | Moderate | High |

Future Trends: Innovations on the Horizon for Rice Milling Industry

The future landscape of the rice milling industry is poised for transformative innovations that promise to revolutionize the way rice is processed, elevating efficiency and quality. Automation is central to this evolution, with advanced technologies paving the way for fully automated rice mills. These facilities will integrate Artificial Intelligence (AI) and Machine Learning (ML) to enhance precision in milling, optimize energy consumption, and reduce waste. As a result, millers will enjoy streamlined operations, allowing them to produce higher-grade rice consistently while adapting quickly to market trends. Key innovations on the horizon include:

- Smart Sensors: Real-time monitoring of moisture content and grain quality.

- Robotic Process Automation: Automated handling of grain, reducing labor costs and improving safety.

- Blockchain Technology: Enhancing traceability and transparency in the supply chain.

Moreover, sustainable practices will take center stage, with mills developing eco-friendly solutions to combat climate change and resource depletion. Renewable energy sources, such as solar and bioenergy, are expected to power these modernized facilities, significantly reducing their carbon footprint. Additionally, advancements in packaging technology will facilitate the preservation of grain quality, while also appealing to environmentally conscious consumers. Innovations that are likely to become prevalent include:

| Innovation | Description |

|---|---|

| Water Recycling Systems | Efficient reuse of water in processing stages. |

| Energy-Efficient Machinery | Machines designed to minimize energy consumption. |

| Biodegradable Packaging | Environmentally friendly materials for packaging finished products. |

In Conclusion

As we close the chapter on the transformation of grain to gold through the rise of automatic rice mills, it’s clear that this technological evolution is more than just a trend—it’s a revolution. These state-of-the-art machines are redefining efficiency, quality, and sustainability in the rice milling industry, empowering farmers and suppliers alike to harness the true potential of their harvests.

With each automated process, from husking to polishing, we witness not only the elevation of grains but also the economic prospects of communities that depend on this staple crop. As the world’s appetite for rice continues to grow, the innovations in milling technology hold the promise of feeding future generations while preserving valuable resources.

In this journey from field to factory, we have explored the myriad ways automatic rice mills are reshaping the landscape of agribusiness. As we look to the future, one thing is certain: the brilliant alchemy of turning grain into gold is just beginning, and the agricultural tapestry will only grow richer with each advancement. Let us embrace these changes and support the evolution of sustainable practices that nourish both people and the planet.