Rice, a staple food for over half of the world’s population, holds a deep cultural significance in many societies. The journey from paddy field to plate is truly a work of art, with each step carefully crafted to preserve the integrity of this beloved grain. In this article, we will delve into the intricate world of modern rice mill plants, where technology and tradition converge to produce the perfect grains of rice. Join us as we explore the artistry behind one of the world’s oldest and most important crops.

The Evolution of Rice Milling Technology

From ancient hand-pounding methods to the cutting-edge technology of today, the evolution of rice milling has been nothing short of remarkable. Inside the modern rice mill plant, a symphony of machinery works in harmony to transform raw rice grains into the polished white pearls we know and love.

Walk through the bustling plant and you’ll see state-of-the-art machines like the huller and polisher, each playing a vital role in the rice milling process. With precision engineering and automation, these machines ensure the highest quality of rice is produced, meeting the demands of consumers worldwide. The art of rice milling has truly transformed into a science, blending tradition with innovation to create the perfect grain every time.

Innovative Processes for Quality Rice Production

Rice has been a staple food for centuries, but with advancements in technology and agriculture, the process of producing quality rice has evolved. Modern rice mill plants are equipped with innovative processes that ensure the production of high-quality rice that meets the demands of consumers worldwide.

From automated seed selection to state-of-the-art milling machines, every step of the rice production process is carefully monitored and controlled to maintain the quality and purity of the final product. With the use of advanced technology and sustainable practices, modern rice mill plants are not only increasing efficiency but also reducing waste and environmental impact. In today’s fast-paced world, the art of rice production continues to evolve, ensuring that we have access to the finest quality rice for generations to come.

Sustainable Practices for Efficient Rice Mill Plants

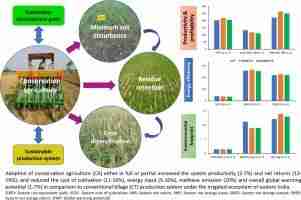

Rice mill plants play a crucial role in the food processing industry, but they also have a significant environmental impact. Implementing sustainable practices in these plants is essential for efficient operation and reducing their carbon footprint. Here are some innovative strategies that can be adopted to make rice mill plants more eco-friendly:

- Energy Efficiency: Installing energy-efficient equipment such as high-pressure steam boilers and LED lighting can significantly reduce energy consumption in rice mill plants.

- Waste Management: Implementing a comprehensive waste management system that includes recycling, composting, and proper disposal of by-products like rice husk can minimize environmental pollution.

- Water Conservation: Utilizing water-saving technologies such as drip irrigation and rainwater harvesting can help reduce water consumption in rice milling processes.

Additionally, investing in renewable energy sources like solar panels and biogas generators can further reduce the carbon footprint of rice mill plants. Implementing these sustainable practices not only benefits the environment but also enhances the overall efficiency and profitability of the plant. By embracing modern technologies and eco-friendly initiatives, rice mill plants can lead the way in sustainable food processing practices.

| Benefit | Description |

| Cost Savings | Implementing sustainable practices can lead to reduced operational costs in the long run. |

| Compliance | Adopting eco-friendly practices helps in complying with environmental regulations and standards. |

Optimizing Output through Automation and Technology Integration

In a world where efficiency and precision are key, the modern rice mill plant stands as a testament to the power of automation and technology integration. Through the art of rice processing, these state-of-the-art facilities are able to maximize output and quality while minimizing human error. By harnessing the latest advancements in machinery and software, rice mill plants have revolutionized the way rice is produced and distributed.

One of the key components of a modern rice mill plant is the automated sorting and grading system. Using advanced sensors and algorithms, this system is able to quickly and accurately identify and separate rice grains based on their size, shape, and quality. This not only ensures a consistent and uniform product, but also reduces the need for manual labor and oversight. Additionally, the integration of cutting-edge milling equipment allows for a more efficient and streamlined production process, further optimizing output and profitability.

In Summary

In conclusion, the modern rice mill plant is an intricate and innovative system that plays a crucial role in the production of rice on a large scale. From cleaning and drying to milling and packaging, each step in the process requires precision and expertise to ensure a high-quality end product. As technology continues to advance, the art of rice production evolves, blending tradition with innovation to meet the demands of a growing global population. The modern rice mill plant stands as a testament to human ingenuity and the importance of agriculture in our daily lives. So next time you enjoy a bowl of rice, remember the intricate journey it took to reach your plate, and appreciate the artistry behind each grain.