In a world where efficiency and productivity reign supreme, the journey of a 4-ton rice mill plant emerges as a captivating narrative of innovation and resilience. This article delves into the intricate processes, cutting-edge technologies, and sustainable practices that define modern rice milling operations. As we explore the evolution of this vital agricultural industry, we’ll uncover the key strategies employed to maximize efficiency, minimize waste, and ensure the highest quality harvest reaches consumers. From the selection of milling equipment to the integration of advanced logistics, every step in the rice mill plant journey reveals the commitment to excellence and adaptation in an ever-changing market. Join us as we navigate through the rice mill’s transformative journey and gain insights into how efficiency can shape not only a plant’s success but also the future of food production.

Understanding the Core Components of a 4 Ton rice mill plant

A 4-ton rice mill plant is designed with several key components that play a crucial role in enhancing productivity and ensuring the quality of the finished product. At the heart of the operation is the paddy separator, which efficiently separates the brown rice from lighter impurities, ensuring that only top-quality rice proceeds further down the line. Following this, the husker removes the outer husk, a vital step that enhances the grain’s aesthetic appeal and marketability. Integral to the milling process is the whitener, which polishes the brown rice and ensures it reaches the desired degree of whiteness, a significant factor influencing consumer preference.

In conjunction with these components, the grading machine ensures consistency by sorting the rice into various sizes, allowing producers to cater to different market segments effectively. Additionally, the packaging unit plays a pivotal role in preserving the quality of the rice and extending its shelf life while facilitating easy handling and distribution. To better understand the workflow, consider the following simplified diagram of the rice mill process:

| Component | Function |

|---|---|

| Paddy Separator | Separates brown rice from impurities |

| Husker | Removes the outer husk from rice |

| Whitener | Polishes brown rice for aesthetic appeal |

| Grading Machine | Sorts rice into various sizes |

| Packaging Unit | Preserves quality and eases distribution |

Streamlining Operations for Optimal Performance

The journey toward maximizing efficiency in a 4-ton rice mill plant involves a meticulous approach to streamlining operations. By deploying automated processing systems, facilities can reduce manual labor and minimize errors that often lead to operational delays. Key enhancements include:

- Integrating real-time monitoring tools to keep track of production efficiency and equipment health.

- Implementing modular layout designs that facilitate smooth material flow, reducing bottlenecks.

- Optimizing scheduled maintenance to anticipate breakdowns before they halt operations.

- Training personnel on the latest technologies and techniques to ensure adaptability.

Furthermore, evaluating performance metrics is essential in identifying areas for growth. Incorporating data-driven decision-making allows managers to analyze key variables, such as:

| Metric | Current Value | Target Value |

|---|---|---|

| Production Rate (tons/hour) | 2.5 | 4 |

| Energy Consumption (kWh/ton) | 50 | 40 |

| Waste Percentage (%) | 5 | 2 |

By continuously monitoring and adjusting these metrics, a rice mill plant can navigate the complexities of production, ultimately paving the way for sustainable growth and increased profitability without compromising quality.

Innovative Technologies Shaping Modern Rice Milling

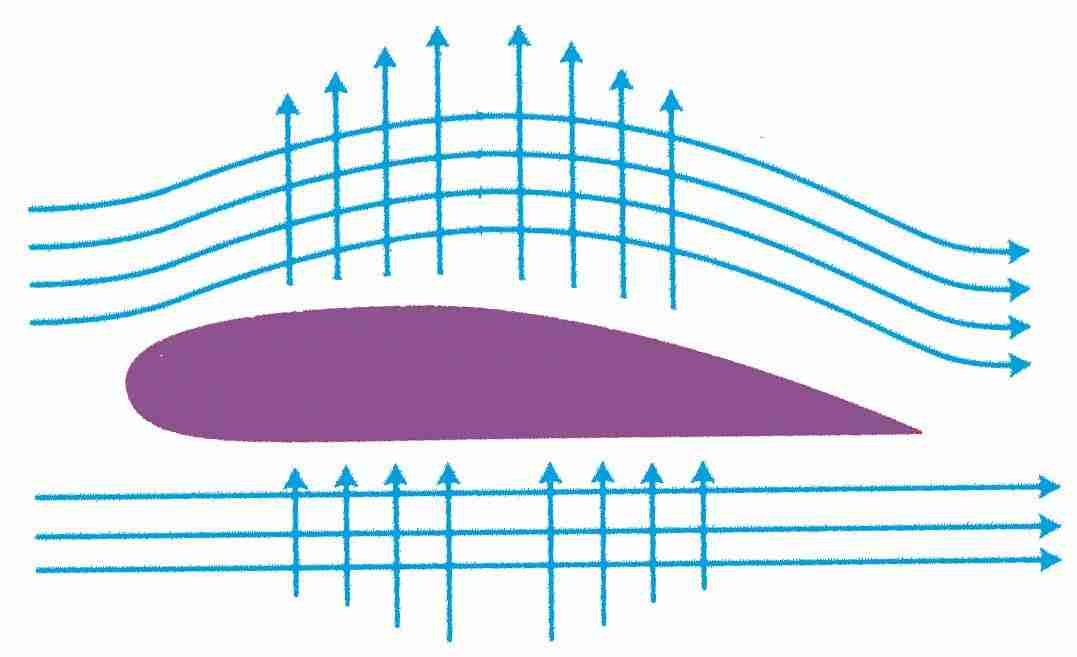

Modern rice milling has undergone a remarkable transformation, driven by innovations that promote efficiency and sustainability. Automation plays a pivotal role, replacing manual processes with cutting-edge machinery equipped with sensors and artificial intelligence. Such enhancements allow for real-time monitoring of the milling process, leading to optimally milled rice with minimal broken grains. Key technologies include:

- Vertical Milling Machines: These machines maximize output by stacking multiple functions, reducing both space and operational time.

- Laser Sorting Systems: Advanced optical sorting technology ensures quality control by detecting and removing impurities with high precision.

- Energy-Efficient Motors: Engaging in sustainability, these motors lower energy consumption, significantly reducing operational costs.

A critical aspect of modern mills is their ability to integrate data analytics into production planning. By leveraging Big Data, mill operators can analyze market trends and adjust output accordingly, thus minimizing waste and optimizing resource allocation. The introduction of smart sensors in grain storage solutions further enhances quality control, providing continuous feedback on moisture levels and pest presence. Below is a concise overview of how technology impacts various facets of rice milling:

| Technology | Impact |

|---|---|

| Automation | Reduces labor costs and enhances throughput |

| Data Analytics | Increases efficiency and reduces waste |

| Smart Storage | Improves grain quality and shelf life |

Sustainable Practices for Long-Term Success in Rice Production

Implementing environmentally sustainable practices is crucial for achieving long-term success in rice production. By adopting techniques that minimize environmental impact, rice mill operators and farmers can enhance productivity while safeguarding natural resources. Some effective methods include:

- Crop Rotation: Alternating rice with legumes or other crops reduces soil depletion and pest prevalence.

- Water Management: Employing drip irrigation and rainwater harvesting systems to optimize water use and combat water scarcity.

- Organic Fertilizers: Utilizing compost and green manures to enhance soil fertility, reducing dependency on chemical fertilizers.

- Integrated Pest Management: Combining biological control methods with minimal chemical applications to maintain pest populations at manageable levels.

In addition to these practices, investing in modern milling technology contributes to sustainable rice production. A well-designed milling process not only boosts efficiency but also reduces energy consumption and waste. Consider the following key performance indicators (KPIs) to measure sustainability in your rice milling operations:

| KPI | Description | Target |

|---|---|---|

| Energy Efficiency | Measure of energy consumed per ton of rice milled | Reduce by 20% within 5 years |

| Water Usage | Liters of water used per ton of rice processed | Reduce by 15% annually |

| Waste Management | Percentage of waste recycled or repurposed | Achieve 50% recycling rate within 3 years |

Insights and Conclusions

As we conclude our exploration of the 4-ton rice mill plant journey, it becomes clear that the pursuit of efficiency is both an art and a science. From the initial planning stages to the intricate mechanics of production, each element plays a crucial role in transforming raw grains into the staple food that nourishes millions. By embracing innovative technologies, optimizing processes, and fostering a culture of continuous improvement, rice mill operators can not only enhance productivity but also contribute to sustainability in the agricultural sector.

This journey is not merely about machinery and output; it reflects a commitment to quality and a deep respect for the resources we utilize. As we move forward, let us remember that the path to maximum efficiency is paved with knowledge, collaboration, and an unwavering dedication to excellence. Whether you are a seasoned mill operator or a newcomer to the industry, the lessons learned from this journey can serve as a beacon, guiding you toward greater accomplishments and a brighter, more efficient future in rice milling.