In the world of culinary arts, few staples hold as much significance as rice, the humble grain that forms the foundation of countless dishes across diverse cultures. Yet, behind its unassuming exterior lies a remarkable journey, starting from the field and culminating in our kitchens. At the heart of this journey is a seemingly simple yet intricate machine: the rice polisher. Often overlooked in the hustle and bustle of food production, the rice polisher plays a pivotal role in achieving the perfect grain texture, flavor, and appearance. “Unveiling the Rice Polisher: Precision in Every Grain” delves into this essential process, exploring the technology and craftsmanship that elevate rice from a basic commodity to a culinary delight. Join us as we peel back the layers of this essential equipment and discover how precision and care transform each grain into a masterpiece poised for gastronomic excellence.

Understanding the Mechanics of Rice Polishing Technology

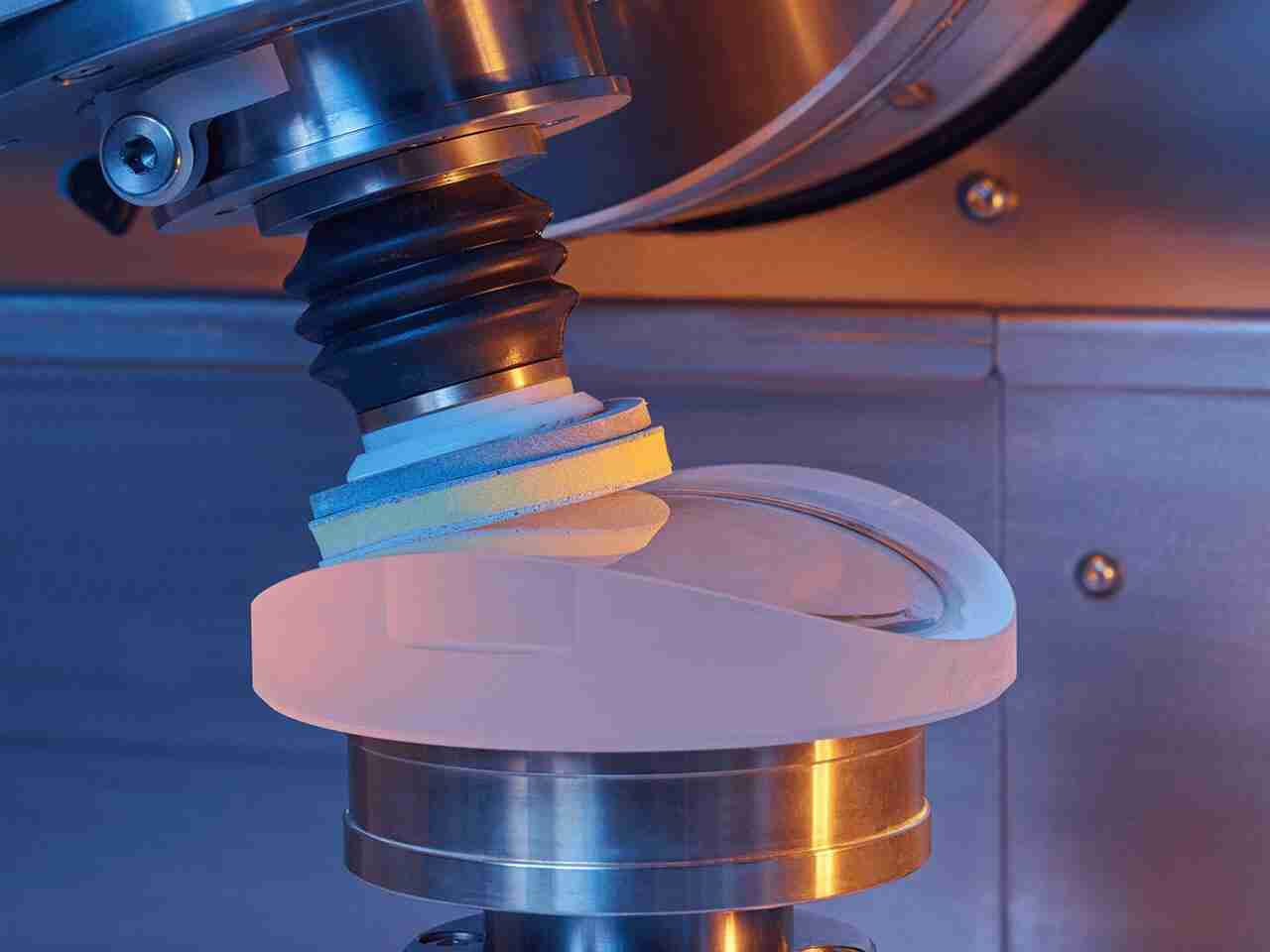

The art of rice polishing has evolved into a sophisticated technology that combines engineering precision with agricultural tradition. At its core, rice polishing technology employs a series of mechanical and physical processes that enhance not only the appearance of rice grains but also their culinary qualities. Polishing machines utilize a combination of friction and airflow to gently remove the outer layers of the rice, which can include bran and husk. This careful elimination not only improves the visual appeal of rice but also plays a critical role in extending its shelf life while preserving essential nutrients.

Modern polishing techniques leverage advanced machine designs that ensure uniform treatment across all grains. These machines are typically characterized by various parameters such as polishing speed, pressure applied, and time duration. Some essential features of contemporary rice polishing systems include:

- Variable speed controls for customized polishing levels

- Integrated air suction systems to eliminate excess debris

- Automated moisture detection to achieve optimal results

Implementing such innovations not only enhances the quality of the final product but also addresses sustainability concerns by maximizing efficiency in raw material utilization. Below is a simple comparison table illustrating different rice polishing techniques:

| Technique | Advantages | Limitations |

|---|---|---|

| Traditional Hand Polishing | Cost-effective, traditional flavor retention | Inconsistent results, labor-intensive |

| Mechanical Polishing | Efficiency, uniform results | Higher initial investment, potential nutrient loss |

| Infrared Polishing | Fast processing, minimal damage to grains | Requires specialized equipment, higher operational costs |

The Impact of Precision Polishing on Rice Quality

Precision polishing is revolutionizing the rice milling industry by enhancing the quality of rice grains, transforming them into a staple that meets both culinary and nutritional expectations. The process meticulously removes the outer layers of the rice grain, thereby significantly impacting its texture, appearance, and overall quality. This advanced technique not only enhances the whiteness and luster of the rice, making it more appealing to consumers, but it also helps to retain essential nutrients that could otherwise be lost through traditional milling methods.

Moreover, precision polishing contributes to the rice’s shelf life, which is an important factor for both retailers and consumers. By minimizing the damaged grains and maintaining the integrity of each individual grain, this method leads to improved cooking qualities. The benefits of precision polishing can be summarized as follows:

- Enhanced visual appeal: Clear and shiny grains attract consumers.

- Improved cooking performance: Consistent size leads to even cooking.

- Extended shelf life: Reduced rancidity means longer usability.

- Nutritional retention: Preserving vitamins and minerals for better health.

Choosing the Right Rice Polisher for Your Needs

When it comes to selecting the ideal rice polisher, understanding the diverse options available is essential to meet your specific needs. Considerations such as capacity, efficiency, and design are paramount. Depending on whether you’re a small-scale farmer, a restaurant owner, or part of a large-scale production line, your choice of a rice polisher will vary. Here are a few key factors to take into account:

- Capacity: Match the polisher to your output requirements; small machines are suited for home use while larger ones cater to commercial needs.

- Technology: Look for advanced features, such as touch screens or automated polishing cycles, that enhance usability and control.

- Energy Efficiency: Considering energy consumption can greatly impact operational costs, especially in large-scale settings.

- Maintenance: Opt for models that are easy to disassemble and clean to ensure longevity and consistent performance.

Furthermore, evaluating the type of polishing mechanism can significantly affect the quality of the finished product. Here’s a quick comparison table of common polishing technologies available in the market:

| Polishing Type | Best Use | Advantages |

|---|---|---|

| Mechanical | Small to Medium Scale | Cost-effective and durable |

| Waterless Air Polishing | Commercial | Less waste and higher polish quality |

| Hybrid Models | All scales | Versatile, balancing cost and quality |

By weighing these attributes against your operational goals and desired rice quality, you can make a well-informed decision. Each rice polisher has its nuances, and understanding these will pave the way for a fruitful investment.

Best Practices for Maintaining Your Rice Polisher

To achieve peak performance and longevity from your rice polisher, establish a routine maintenance schedule. Regular cleaning is paramount; after each use, ensure that the interior components are free from residual rice husks and other debris. Utilize a soft brush or cloth to gently wipe down surfaces, paying particular attention to the polishing chamber. This will not only maintain the functionality but also prevent cross-contamination between batches. Check the motor and electrical parts systematically for any signs of wear and tear; a malfunctioning motor can dramatically alter the quality of the polished rice.

It’s also advisable to conduct a thorough inspection of key components periodically. Replace worn belts and seals promptly to avoid diminished performance. To assist in your maintenance routine, keep a detailed log that tracks the dates of each service and any replacements made. You may also find it useful to refer to manufacturer guidelines for specific recommendations. Consider utilizing a dedicated maintenance kit tailored for your model, as this will ensure you have all necessary tools at hand. Below is a simple guideline table for reference:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean polishing chamber | After every use | Use a soft brush or cloth |

| Inspect motor and electrical parts | Monthly | Look for wear and tear |

| Replace belts and seals | As needed | Follow manufacturer’s guidelines |

| Log maintenance activities | Ongoing | Keep a detailed record |

In Retrospect

As we conclude our exploration of the rice polisher, it’s clear that this seemingly simple device encapsulates a world of precision and craftsmanship. From the careful engineering that ensures each grain is polished to perfection, to the intricate balance between tradition and innovation, the rice polisher stands as a testament to the dedication and vision of those who strive for excellence in rice production.

The journey of rice, from field to table, is one that deserves celebration. With the rice polisher at the helm, we not only enhance the aesthetics of this staple but also elevate its nutritional quality, ensuring that each grain tells a story of care and innovation. As we embrace the future of food processing, it is essential to recognize the role of such technologies in shaping sustainable and efficient agricultural practices.

the rice polisher is not just a tool; it’s a key player in sustaining livelihoods, preserving cultures, and nourishing communities worldwide. As we continue to unveil the layers of our food systems, let us hold in high regard the precision that goes into every grain, recognizing that behind each polished kernel lies a commitment to quality and the promise of a better tomorrow.