Unveiling the Journey: Inside a Paddy Processing Factory

Nestled in the heart of verdant rice fields, where golden grains dance with the rhythm of the breeze, the paddy processing factory stands as a remarkable bridge between nature’s bounty and our daily sustenance. This unseen world transforms humble paddy into the polished rice that graces our dining tables, a process steeped in tradition yet powered by modern technology. In this article, we invite you to step inside a paddy processing facility, unveiling the intricate journey that each grain undertakes—from harvesting to milling and packaging. Explore the meticulous methods employed, the intricate machinery at work, and the dedicated individuals who bring this essential staple to life. Join us as we illuminate the path of rice, revealing not just the processes involved but also the stories that resonate within this vital industry.

Exploring the Lifecycle of Paddy: From Grain to Final Product

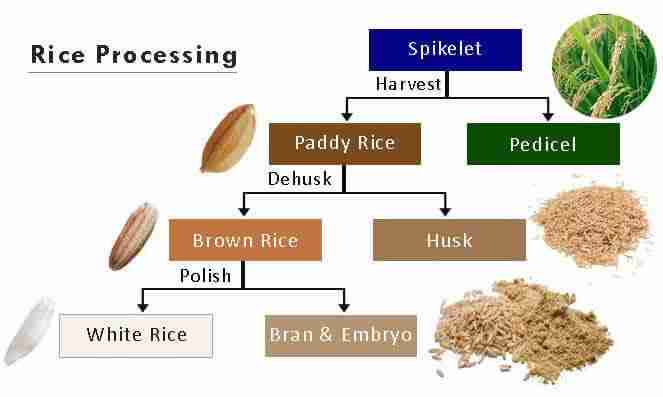

As paddy arrives at the processing factory, the journey begins from its natural state—a golden harvest waiting to be transformed. The first step is sorting and cleaning, where the grains are meticulously examined to remove impurities such as stones, dirt, and broken kernels. This phase is crucial to ensure that only the best quality grains proceed through the stages of processing. The cleaned paddy is then subjected to the hulling process, where the outer husk is removed, revealing the brown rice beneath. This transformation is akin to peeling away the layers to uncover a hidden treasure.

After hulling, the brown rice undergoes milling, where it is polished and further refined. The goal here is to achieve white rice, which is the end product that consumers are familiar with. During this process, not only does the outer bran layer get removed, but also valuable nutrients are stripped away, sparking debates on health and nutrition. To illustrate the nutritional differences, consider the following table:

| Type of Rice | Bran Layer | Nutritional Benefits |

|---|---|---|

| Brown Rice | Intact | High in fiber, vitamins, and minerals |

| White Rice | Removed | Lower in fiber, enriched with some vitamins |

Once milled, the rice is subjected to a final quality control phase, ensuring that only the best grains make it to packaging. It is here that the rice is weighed, packaged, and branded, ready to embark on its journey to markets and kitchens around the world. This intricate process, blending traditional techniques with modern technology, creates a synergy that enhances the quality and sustainability of rice production.

Behind the Scenes: Technology and Techniques in Paddy Processing

Within the bustling confines of a paddy processing factory, cutting-edge technology and time-honored methods converge to transform golden grains into market-ready rice. State-of-the-art machinery plays a vital role, streamlining the production process through features such as:

- Automated Hulling Machines: Efficiently remove the husk from paddy grains.

- De-stoning Equipment: Ensure that stones and impurities are eliminated.

- Color Sorting Machines: Use advanced optical technology to segregate discolored grains.

- Packaging Systems: Facilitate quick and precise bulk packing.

By incorporating these innovations, factories are able to maintain a consistent level of quality while boosting productivity.

However, the heart of paddy processing also lies in the traditional techniques that have been passed down through generations. Skilled workers employ methods that go beyond mere automation to enhance the quality of the end product, such as:

- Manual Inspection: Allowing for meticulous evaluation of rice quality.

- Natural Drying: Utilizing sunlight to dry grains, which enhances flavor.

- Community Knowledge: Leveraging local knowledge on grain varieties.

Such practices underscore the essential balance between modern technology and traditional wisdom, crafting grains that are not just processed, but celebrated for their heritage.

Quality Control in Action: Ensuring Standards at Every Stage

In the bustling environment of a paddy processing factory, precision is key. Quality control measures are effectively interwoven into every phase of production to guarantee that each grain of rice meets the highest standards. From the moment paddy arrives, meticulous checks begin, ensuring that only the best raw materials proceed through the milling process. Workers conduct visual inspections and utilize advanced technology to identify impurities and defects. This proactive approach is vital as it helps in:

- Sorting out subpar grains to maintain purity.

- Monitoring humidity levels during storage to prevent spoilage.

- Conducting regular machinery audits to avoid mechanical failures.

As the paddy continues through its journey, quality control does not wane. Each stage, from husking to polishing, is accompanied by rigorous testing protocols that analyze factors such as moisture content, grain length, and cleanliness. Visual indicators are supplemented by data collection, ensuring consistency throughout the production process. Quality metrics are systematically recorded and compared against established benchmarks, illustrating our commitment to excellence. The following table summarizes key quality indicators tracked at various stages:

| Stage | Key Quality Indicators |

|---|---|

| Receiving | Impurity Percentage, Moisture Content |

| Husking | Kernel Breakage Rate |

| Polishing | Surface Shine, Grain Length |

| Packing | Weight, Seal Integrity |

Sustainable Practices: Recommendations for Eco-Friendly Paddy Processing

Embracing eco-friendly technologies in the paddy processing industry not only enhances operational efficiency but also plays a crucial role in preserving our environment. A few innovative practices can significantly reduce the ecological footprint of processing facilities. For instance, the integration of solar panels for energy needs can lower reliance on fossil fuels, while rainwater harvesting systems can help mitigate water scarcity issues. Additionally, incorporating bioenergy systems utilizing agricultural waste not only provides renewable energy but also reduces waste disposal challenges.

Moreover, the implementation of waste management strategies ensures minimal environmental harm. Facilities can adopt methods that include:

- Composting organic waste to create nutrient-rich fertilizers, thereby promoting soil health.

- Recycling packaging materials to lessen landfill waste.

- Utilizing energy-efficient machinery to minimize energy consumption during processing.

By investing in these sustainable approaches, paddy processing factories can lead the way towards a greener future while still maintaining high productivity levels.

Final Thoughts

As we draw the curtain on our exploration of the intricate world within a paddy processing factory, we come to appreciate the marriage of tradition and technology that defines this industry. From the rhythmic sounds of machinery to the meticulous hands that sort, clean, and package each grain, we have witnessed the dedication and expertise required to transform paddy into the staple that nourishes millions.

This journey is not just about the grains; it is a narrative woven with the stories of the workers, the innovation of processes, and the commitment to quality that underpins every step. As consumers, we may often overlook the complexity behind our food, but the path from field to table is rich with effort and care.

In recognizing the journey of paddy processing, we invite you to reflect on the broader food systems that sustain us all, fostering an appreciation for the labor and technology that come together in this remarkable transformation. The next time you savor a bowl of rice, remember the voyage it undertook and the hands that made it possible. In unveiling this journey, may we cultivate a deeper connection to the food we cherish, honoring both its origins and the communities that bring it to our plates.