In the heart of rice-growing regions across the globe, a silent revolution is taking place. As the sun rises over verdant fields, casting golden hues on ripening paddy, farmers are increasingly turning to technology to streamline the age-old process of rice production. Enter the paddy processing machines—a beacon of innovation that promises to unlock efficiency in an industry deeply rooted in tradition. These machines, designed to enhance productivity while minimizing labor intensity, are transforming how paddy is processed, stored, and prepared for market. This article explores the rise of these technological marvels, examining their impact on agricultural practices, economic growth, and the future of food security. With the world’s population steadily increasing and the demand for rice soaring, understanding the shift towards mechanization is more crucial than ever. Join us as we delve into the intricate workings of paddy processing machines and their pivotal role in shaping the landscape of modern agriculture.

The Evolution of Paddy Processing Technology and Its Impact on Agriculture

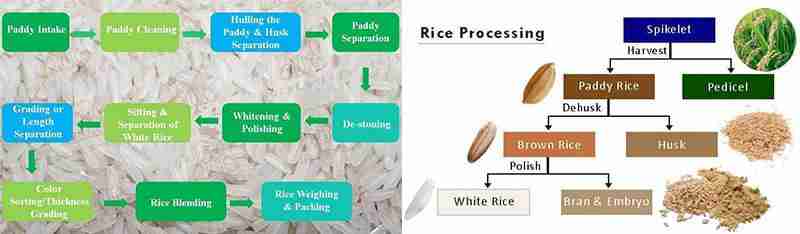

The journey of paddy processing technology has transformed agriculture into a more efficient and productive sector. This evolution began with traditional methods that relied heavily on manual labor and basic tools, which often led to variable quality and significant post-harvest losses. However, the emergence of modern paddy processing machines has brought about a revolutionary shift. With innovations such as multi-functional hullers, de-stoners, and milling machines, farmers can now process paddy at a fraction of the time and cost. These machines not only increase the output but also enhance the quality of rice, making it more marketable.

The integration of technology has not only streamlined production but has also had a profound impact on rural economies. By decreasing the physical labor required and improving processing speeds, these advancements have enabled farmers to diversify their operations and explore value-added products such as rice bran oil and gluten-free offerings. Moreover, the advent of sustainable practices in paddy processing has contributed to environmental conservation, paving the way for a greener agricultural approach. Below is a table that showcases the key technological advancements that have occurred in paddy processing:

| Technology | Benefits |

|---|---|

| Mechanical Hullers | Reduce milling time and increase output. |

| De-stoning Machines | Enhance product purity, minimizing contamination. |

| Automated Packaging | Ensure consistent quality and freshness. |

| Solar Dryers | Utilize renewable energy for drying paddy, reducing costs. |

As we witness these advancements, it is evident that the future of paddy processing will continue to pivot towards efficiency and sustainability, reshaping the agricultural landscape for generations to come. The synergy between technology and traditional practices creates a resilient framework that not only bolsters productivity but also nurtures the environment, ensuring that the needs of the present are met without compromising future generations.

Maximizing Yield: How Paddy Processing Machines Enhance Productivity

The conversion of raw paddy into consumable rice has traditionally been a labor-intensive task, often hampered by inefficiencies in manual processing. With the advent of modern paddy processing machines, the agricultural landscape is witnessing a remarkable transformation. Paddy processing machines are designed to automate various stages of rice milling, which significantly streamlines the production process. This automation contributes to a dramatic reduction in labor costs and time consumption, ultimately leading to enhanced throughput and superior grain quality. The integration of advanced technology, such as sensor-based systems for quality control, allows these machines to optimize every aspect of processing, from husking to polishing, ensuring minimal grain loss.

Moreover, the benefits extend beyond just increased output. The use of these machines also promotes sustainability in rice production. By maximizing yield through efficient processing, farmers can reduce waste and improve resource management. Some notable features of contemporary paddy processing machines include:

- Variable speed controls for tailored processing rates

- Energy efficiency that aligns with eco-friendly practices

- Versatility to handle different rice varieties

Such innovations not only facilitate increased harvest but also pave the way for better market competitiveness, allowing farmers to meet the growing demand for rice while adhering to sustainable practices.

Cost-Benefit Analysis of Investing in Modern Paddy Processing Solutions

When considering the transition to modern paddy processing solutions, a thorough exploration of the costs and benefits is essential. On the one hand, investments in advanced machinery require initial capital expenditure, operational training, and maintenance costs. However, these expenses can often be offset by the tangible benefits that accrue over time. For instance, automated systems minimize labor costs and significantly reduce processing time, meaning more produce can be processed in less time. Moreover, enhanced technological precision leads to higher yields and superior quality, which can attract premium prices in the market. Thus, modern machines can ensure a higher return on investment (ROI) through efficiency and quality improvements.

Furthermore, evaluating the long-term savings versus the immediate outlays reveals a compelling narrative for stakeholders. Consider the following key benefits:

- Increased Yield – Superior machinery can lead to better husking and milling, preserving more grain and reducing loss.

- Energy Efficiency – Modern machines use less energy, which translates to lower utility bills over time.

- Labor Reduction – Automation decreases reliance on manual labor, mitigating risks associated with labor shortages and increasing overall productivity.

- Market Competitiveness – High-quality output positions producers more favorably in the competitive market, enhancing sales opportunities.

Below is a concise table that outlines the potential returns when investing in modern processing machinery:

| Investment Type | Initial Cost | Projected Annual Savings | Payback Period |

|---|---|---|---|

| Automated Paddy Mill | $150,000 | $45,000 | 3.33 Years |

| Advanced Husking Machine | $80,000 | $30,000 | 2.67 Years |

| Energy-Efficient Dryer | $50,000 | $20,000 | 2.50 Years |

This cost-benefit perspective demonstrates that while the upfront investment may appear daunting, the potential for increased revenue and decreased operating costs makes modern paddy processing solutions an attractive option for producers looking to thrive in an evolving agricultural landscape.

Sustainability in Paddy Processing: Eco-Friendly Innovations and Practices

The landscape of paddy processing is undergoing a significant transformation as innovators prioritize eco-friendliness in their operations. New machines and technologies are being developed with a focus on minimizing waste and maximizing efficiency. Solar-powered milling facilities exemplify this trend, harnessing renewable energy to reduce dependence on fossil fuels. Additionally, advancements in water conservation practices are being integrated into machinery design, enabling processors to use up to 50% less water compared to traditional methods. This shift not only cuts operational costs but also protects the vital water resources in farming communities.

Moreover, sustainable practices extend beyond mere machinery upgrades; they encompass the entire paddy processing ecosystem. For instance, many processors are adopting biomass energy systems that utilize rice husks and straw as viable energy sources. This not only provides an alternative to conventional fuels but also helps in reducing greenhouse gas emissions. Complementing these innovations, initiatives to improve nutrient recovery from by-products are gaining traction, turning waste into value. When integrated, these practices foster an environment where both the economy and the ecosystem thrive, paving the way for a future where paddy processing is both efficient and environmentally responsible.

Concluding Remarks

the evolution of paddy processing machines represents a significant leap forward in agricultural efficiency. As we’ve explored, the integration of advanced technology into this essential industry not only streamlines operations but also enhances the quality of the final product. By reducing labor costs and optimizing time, these machines pave the way for a more sustainable and productive future in rice production.

As the demand for food grows alongside the world’s population, embracing such innovations will be crucial for farmers aiming to maximize yields while minimizing their environmental footprint. The rise of paddy processing machines is not merely a trend; it signifies a shift toward more intelligent farming practices that honor both tradition and progress.

As we move forward, it will be important to monitor these advancements and their impacts on the agricultural landscape, ensuring they continue to serve not just the needs of today but also inspire a more resilient and efficient tomorrow. The journey towards agricultural innovation is just beginning, and the promise of paddy processing machines is only the tip of the iceberg. Let us remain open to the possibilities as we unlock new levels of efficiency and sustainability in our global food systems.