Transforming Grain: Inside the Paddy Processing Plant

In the heart of agricultural landscapes where golden fields sway gently in the wind, rice reigns as a staple that nourishes billions across the globe. Yet, the journey from paddy to polished grain is a fascinating narrative often overlooked. Within the confines of the paddy processing plant, an intricate dance of technology and tradition unfolds, transforming raw, unassuming grains into the culinary cornerstone of countless cultures. This article invites you to step inside these bustling facilities, where each mechanism hums with purpose, and every grain tells a story of cultivation, innovation, and sustainability. Join us as we explore the meticulous processes that breathe life into this vital cereal, revealing not only the journey of the grain but also the livelihoods intertwined with its journey from field to fork.

Understanding the Paddy Processing Journey from Field to Fork

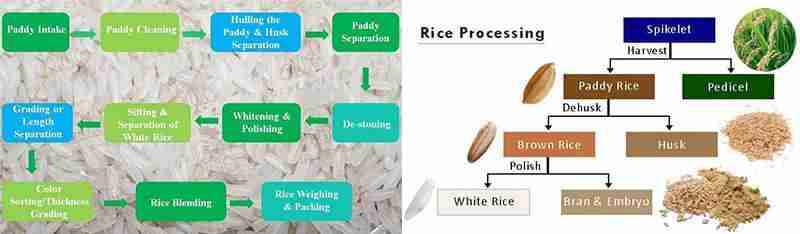

The journey of paddy from the vast, green fields to our plates is nothing short of remarkable. It all begins in the paddy fields, where the grains are nurtured under the right climatic conditions and careful cultivation methods. Once harvested, the real transformation starts in the processing plant. Here, the grains undergo several critical stages, including drying, hulling, and polishing, all designed to enhance quality while preserving the essential nutrients. During these processes, grain quality is meticulously checked, ensuring only the best reaches the consumer. Factors such as moisture content, foreign material, and grading standards are all assessed to maintain high-quality output.

In a modern paddy processing plant, technology plays an essential role in streamlining operations and improving efficiency. Striking a balance between traditional practices and modern techniques can drastically influence the end product’s flavor and nutritional value. Key steps involved in the processing include:

- Drying: Reducing moisture content to prevent spoilage.

- Hulling: Removing the husk to retrieve the brown rice.

- Polishing: Enhancing appearance and taste.

- Sorting: Ensuring uniformity and quality through automated systems.

At the end of this extensive process, it is essential to understand the nutritional implications. Below is a quick comparison of rice before and after processing:

| Stage | Nutritional Value |

|---|---|

| Raw Paddy | High fiber, vitamins, and minerals |

| Brown Rice | Retains bran and germ, high in nutrients |

| White Rice | Lower fiber and vitamin content |

Understanding these stages provides insight into the care and precision that goes into each grain. As consumers become increasingly aware, the value of quality processing becomes clear, elevating the simple grain to a staple enjoyed worldwide.

Key Technologies Revolutionizing Grain Processing Efficiency

In the quest for efficiency, modern paddy processing plants are increasingly adopting cutting-edge technologies that streamline operations and enhance yield. Automated sorting systems equipped with optical sensors are revolutionizing seed selection, ensuring that only the highest quality grains progress through the processing stages. This technology dramatically reduces waste and increases the overall quality of the final product. Additionally, advanced milling machines optimize the husking and polishing processes, allowing operators to achieve consistent results while minimizing energy consumption.

Another game-changer in grain processing is data analytics. By implementing IoT devices and real-time monitoring systems, plants can collect and analyze data to identify bottlenecks and optimize workflows. Predictive maintenance powered by machine learning algorithms anticipates equipment failures before they occur, significantly reducing downtime and maintenance costs. These innovations are paving the way for a more sustainable and efficient future in grain processing, enabling businesses to meet the growing demand while adhering to environmental regulations.

| Technology | Benefits |

|---|---|

| Automated Sorting Systems | Improved quality control and reduced waste |

| Advanced Milling Machines | Consistent results and lower energy usage |

| IoT and Data Analytics | Real-time monitoring and optimized workflows |

| Predictive Maintenance | Decreased downtime and maintenance costs |

Quality Control Measures That Ensure Premium Rice Production

To ensure the production of premium rice, processing plants implement rigorous quality control measures at every stage of the grain transformation. Each batch of paddy undergoes a thorough inspection to assess its initial quality, with focus points including moisture content, purity, and foreign matter. These evaluations help identify any potential issues before processing begins, allowing the plant to maintain high standards right from the start. Regular training for staff further enhances the ability to recognize quality issues, ensuring that everyone is well-equipped to manage the intricate details of rice processing.

During the milling process, advanced technology plays a pivotal role in maintaining quality. Automated systems are utilized to monitor and control various parameters such as temperature and time, which are crucial for achieving optimal texture and flavor in the final product. After milling, every batch is sampled and subjected to sensory evaluations, where trained panels assess characteristics like aroma, grain integrity, and visual appeal. The results from these tests are documented and reviewed, guiding any necessary adjustments in production. The table below provides insight into the different quality parameters monitored throughout the rice production process:

| Quality Parameter | Description | Importance |

|---|---|---|

| Moisture Content | Measurement of water within the grain | Prevents spoilage and maintains quality |

| Purity | Presence of foreign grains or debris | Ensures a clean and premium product |

| Grain Integrity | Physical state of the rice grains | Enhances cooking quality and consumer appeal |

Sustainable Practices in Paddy Processing for Future Generations

As the world moves towards a more eco-conscious mindset, the paddy processing industry is stepping up with innovative methods that prioritize sustainability without compromising quality. Some of the key practices emerging in this field include:

- Water Recycling: The industry is adopting advanced systems to recycle water used in processing, significantly reducing overall consumption and minimizing waste.

- Energy Efficiency: Upgraded machinery and technology help to lower energy consumption, harnessing renewable sources wherever feasible, such as solar or wind energy.

- Biomass Utilization: By-products from paddy processing, including husks and stalks, are repurposed for bioenergy, reducing landfill waste and generating power.

Moreover, sustainable practices extend beyond the processing plant. The use of eco-friendly packaging is gaining traction, providing protection for grains while minimizing plastic use. Furthermore, collaboration with local farmers ensures that practices are aligned with environmentally responsible farming methods, fostering a circular economy. A closer look at the benefits includes:

| Benefit | Description |

|---|---|

| Reduced Carbon Footprint | Lower greenhouse gas emissions through efficient processing. |

| Community Engagement | Supporting local farmers through sustainable sourcing initiatives. |

| Enhanced Product Quality | Maintaining purity while adhering to organic and eco-friendly standards. |

To Conclude

As we conclude our journey inside the paddy processing plant, it becomes clear that the transformation of grain is much more than a mere industrial process; it is a delicate interplay of tradition and technology, of labor and innovation. The rhythmic hum of machinery echoes not just the sounds of production, but also the stories of communities nourished by the grains that pass through these walls. From the careful harvesting in the fields to the final polished rice ready for market, each stage of processing represents a commitment to quality and sustainability.

In an age where food security and environmental concerns are paramount, the dynamics within these processing plants serve as a microcosm for the broader challenges facing the agricultural sector. By embracing advancements in technology while honoring age-old practices, paddy processing plants position themselves at the forefront of the food industry’s evolution.

As we leave the processing line today, we carry with us a deeper appreciation for the journey that begins in the fields and ends on our plates. The next time you savor a grain of rice, remember the myriad of hands, machines, and techniques that made it possible. In this intricate dance of transformation, every grain tells a story worth sharing.