In the heart of the countryside, where verdant fields stretch as far as the eye can see, lies a hidden gem of agricultural innovation – the paddy processing factory. Here, amidst the tranquil hum of machinery and the earthy scent of freshly harvested grains, the art of rice comes to life in all its splendor. Join us on a journey through the inner workings of this bustling hub of rice production, where tradition and technology merge seamlessly to deliver the golden grains that grace our tables. Welcome to the enchanting world of paddy processing - where every kernel tells a story.

1. Unveiling the Intricate Process of Rice Production

Rice production is a fascinating and intricate process that involves several steps to transform raw paddy into the familiar white grains we consume every day. The journey starts in the paddy fields, where rice is cultivated and harvested by skilled laborers. The harvested paddy is then transported to processing factories, where it goes through a series of steps to become the rice we know and love.

Inside a paddy processing factory, the paddy undergoes cleaning, husking, milling, and polishing to remove the outer layers and reveal the edible grain within. Each step in the process requires precision and expertise to ensure the quality and integrity of the final product. From the hands of the farmers to the meticulous care of the factory workers, the art of rice production is truly a labor of love that results in a staple food enjoyed by billions worldwide.

2. The Science Behind Perfecting White Rice Quality

Ever wonder what goes into producing the perfect bowl of white rice? At the heart of every grain is a meticulous process that combines science and artistry. In a paddy processing factory, the journey of rice begins with carefully selected raw materials from local farmers. The grains are then cleaned and polished to remove impurities, ensuring a pristine final product.

Through advanced milling techniques and precise measurements, the factory ensures that each grain of rice is uniform in size and texture. This attention to detail is what sets apart high-quality white rice from the rest. lies in the delicate balance of moisture content, milling pressure, and polishing duration. By mastering these elements, the factory is able to produce rice that is not only visually appealing but also boasts a superior taste and aroma.

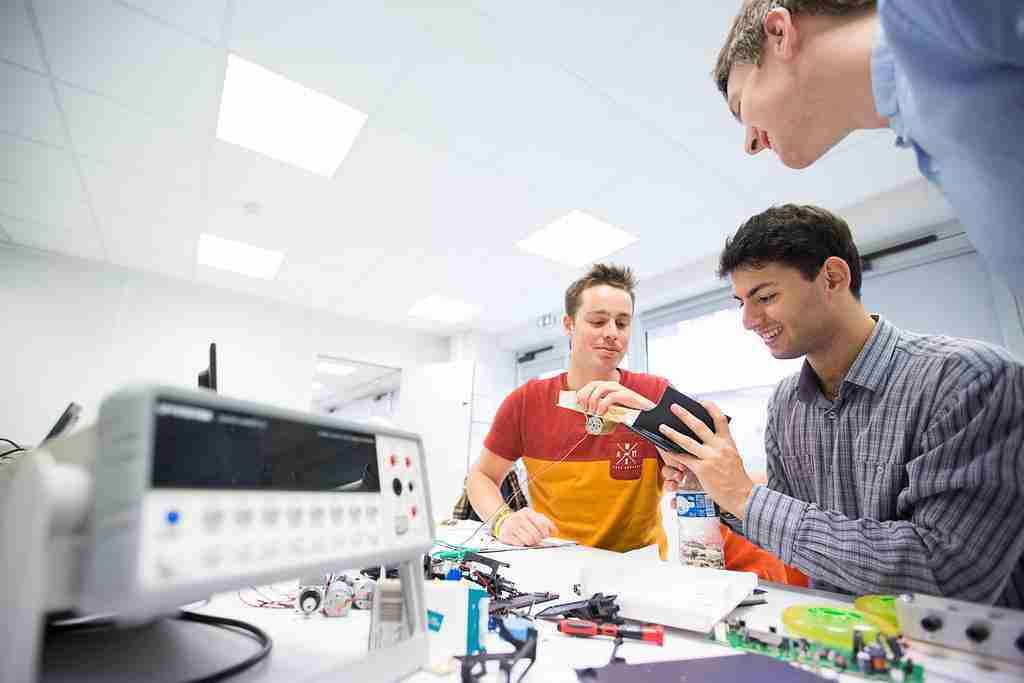

3. Innovative Technologies Revolutionizing Paddy Processing

Imagine walking into a state-of-the-art paddy processing factory where innovative technologies are revolutionizing the way rice is produced. Machines humming, steam billowing, and workers bustling about, each step of the process is a fascinating dance of precision and efficiency. From the moment the freshly harvested paddy arrives at the facility to the final packaging of perfectly polished rice grains, every detail is carefully monitored and controlled.

One of the key technologies transforming paddy processing is the use of automated sorting machines. These high-tech devices use advanced sensors and algorithms to quickly and accurately separate the good grains from the defective ones. This ensures that only the highest quality rice makes it to the consumer, reducing waste and improving overall efficiency. Additionally, cutting-edge milling machines are able to process rice at lightning speed, significantly increasing output without compromising on quality. With these innovations, the art of rice production has truly reached new heights.

4. Best Practices for Maintaining Hygiene Standards in a Rice Factory

One of the key aspects of maintaining hygiene standards in a rice factory is ensuring that all surfaces and equipment are kept clean at all times. This includes regularly sanitizing production areas, storage containers, and machinery to prevent contamination. Implementing a strict cleaning schedule and providing proper training to employees on hygiene practices are essential components of achieving this goal.

Another best practice for maintaining hygiene standards in a rice factory is to regularly monitor and control the moisture levels in the storage and production areas. Excess moisture can lead to the growth of bacteria and mold, which can contaminate the rice and pose health risks to consumers. Installing dehumidifiers and conducting routine checks on moisture levels can help prevent these issues from occurring. Additionally, ensuring that proper ventilation systems are in place can help regulate temperature and airflow, further minimizing the risk of contamination.

Key Takeaways

As we conclude our exploration of “The Art of Rice” inside a paddy processing factory, we are left in awe of the intricate and fascinating processes involved in bringing this staple food to our plates. From the rhythmic planting and harvesting in the fields to the precise milling and packaging in the factory, every step in the production of rice is a testament to human ingenuity and dedication.

Next time you sit down to enjoy a bowl of rice, take a moment to appreciate the artistry that goes into each grain. The journey of rice from paddy to plate is a true testament to the beauty and complexity of the world around us. Just as each grain of rice plays a vital role in nourishing our bodies, so too does the art of rice production enrich our understanding and appreciation of the food we eat.

Thank you for joining us on this enlightening journey through the paddy processing factory, and may you continue to savor the art of rice in all its forms.