Inside the Paddy Processing Factory: A Journey from Grain to Bowl

Nestled amidst sprawling fields of verdant green, where the gentle rustle of rice stalks harmonizes with the soft whisper of the wind, lies a world that transforms the humble paddy into the staple grain gracing our tables. The paddy processing factory, a marvel of modern ingenuity, stands as a bridge between nature’s bounty and the comforting bowls of rice that appear in kitchens around the globe. This article embarks on a journey into the heart of this intricate process, unveiling the steps that each grain undergoes—from harvesting and husking to milling and packaging. Join us as we explore the delicate balance of tradition and technology, the labor of love that fuels this vital industry, and the unseen paths that bring nourishment from field to fork. In discovering the life cycle of rice, we reveal not just the mechanics of production, but also the stories of the people and communities that thrive within this essential food ecosystem.

Exploring Paddy: Understanding the Variety and Quality of Raw Grain

As we venture deeper into the intricate world of paddy processing, we encounter an astonishing variety of raw grain that serves as the backbone of countless cuisines around the globe. Each type of paddy possesses unique characteristics that contribute to its flavor, texture, and nutritional profile. The categorization of paddy largely revolves around grain size and shape, which can broadly be divided into:

- Short Grain: Typically round and plump, this variety cooks to a sticky consistency, making it ideal for sushi and risottos.

- Medium Grain: With a slightly longer shape, medium-grain paddy strikes a perfect balance between moist and fluffy, suitable for a variety of dishes.

- Long Grain: Characterized by its slender appearance, long-grain is known for remaining separate and fluffy after cooking, perfect for pilafs and stir-fries.

Beyond the grain type, various quality parameters dictate the selection of paddy for processing. Factors such as moisture content, purity, and the presence of broken grains play a pivotal role in determining the final product’s marketability. The table below summarizes key quality indicators and their impact on paddy classification:

| Quality Indicator | Description | Impact on Classification |

|---|---|---|

| Moisture Content | Percentage of water in grains | Affects storage and shelf life |

| Purity | Presence of broken grains and impurities | Determines market value |

| Kernel Length | Measurement of the grain’s length | Defines classification category |

The Milling Process: Transforming Paddy into Rice with Precision

The transformation of paddy into polished rice is a delicate art, meticulously executed through a series of precise milling stages. The journey begins with cleaning, where the harvested paddy is thoroughly rid of impurities such as stones, dirt, and chaff. This ensures that what enters the milling machines is of the highest quality. Once cleaned, the paddy undergoes soaking and steaming, which softens the grain, preparing it for the subsequent hulling process. The husk is removed, unveiling the brown rice that lies within, retaining much of its natural nutrients.

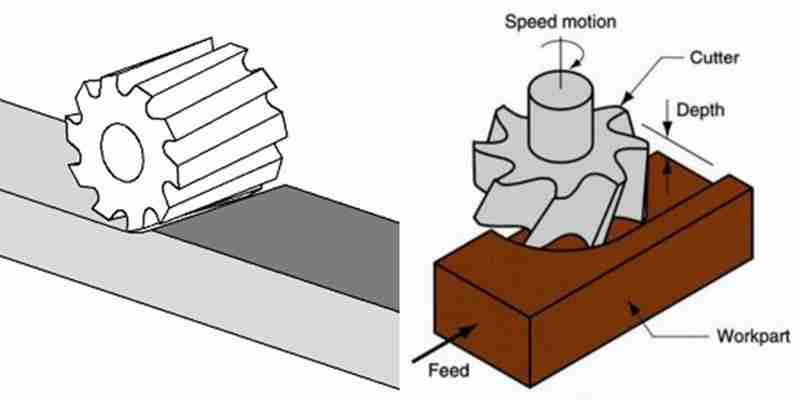

As the process progresses, the brown rice is polished to achieve the preferred white rice appearance. This is done through milling, which involves multiple stages of grinding and airing to remove the bran layers. It’s during this phase that a precise balance must be struck—too much milling can result in nutrient loss, while too little leaves the rice with an undesirable texture. The final steps include sorting and packaging, where the rice is classified based on quality, ensuring that only the finest grains make it to our kitchens. A typical milling factory will also keep track of production metrics:

| Stage | Description | Key Equipment |

|---|---|---|

| Cleaning | Removal of impurities | Destoner, Cleaner |

| Hulling | Separation of husk from grain | Hullers |

| Milling | Polishing brown rice | Milling Machines |

| Sorting | Classifying rice by quality | Sorters |

This intricate process is not just about mechanization; it requires skilled supervision and quality control. The commitment to producing premium rice extends beyond milling; factors like moisture control and storage conditions are carefully monitored to ensure that the rice retains its freshness and flavor until it reaches the consumer’s bowl.

The Role of Technology: Innovations Enhancing Efficiency in Processing

In the intricate world of paddy processing, technological advancements have become the backbone of efficiency, transforming raw grains into polished products ready for consumption. From automated milling machines to precision sorting systems, these innovations have streamlined various stages of the processing chain. Key enhancements include:

- Automated Milling: Modern milling equipment reduces the labor intensity and increases throughput by utilizing sensors to optimize grain flow and adjust parameters in real time.

- Optical Sorters: Advanced optical sorting technology improves quality control, rapidly identifying and removing impurities and discolored grains, thus ensuring a higher quality output.

- Data Analytics: Implementing IoT devices provides valuable insights into operational efficiency, allowing for predictive maintenance and optimizing energy use during processing.

To further illustrate the impact of these technologies, consider the following specifications that showcase typical processing improvements:

| Innovation | Efficiency Gain | Quality Improvement |

|---|---|---|

| Automated Milling | 30% increased throughput | Consistent grain quality |

| Optical Sorting | 95% efficiency in impurity removal | Higher grade rice |

| Data Analytics | 20% reduction in downtime | Proactive quality management |

Through these technological enhancements, paddy processing factories have not only increased productivity but also elevated the standard of the final product, facilitating a seamless journey from the field to the dining table. The marriage of innovation and traditional practices ensures that rice continues to be a staple food across the globe, efficiently bridging the gap between farmer and consumer.

Sustainability Practices: Ensuring an Eco-Friendly Journey from Grain to Bowl

In the journey from grain to bowl, maintaining environmentally friendly practices is paramount. At the heart of the paddy processing factory, several initiatives work tirelessly to reduce the ecological footprint of rice production. These practices include:

- Water Conservation: Utilizing advanced irrigation technologies to minimize water usage during cultivation.

- Waste Recycling: Implementing systems to recycle husks and straw, transforming them into bioenergy and organic fertilizers.

- Eco-Friendly Packaging: Opting for biodegradable and recyclable packaging materials to reduce plastic waste in the market.

- Renewable Energy:** Harnessing solar and wind power to fuel processing machinery, lowering dependence on fossil fuels.

Moreover, the factory collaborates with local farmers to advocate for sustainable farming practices. Through workshops and training, producers learn about crop rotation, pest management, and organic farming. This holistic approach not only enhances the quality of the grain but also promotes biodiversity. The result is a sustainable ecosystem that supports both the environment and local economies. Here’s a quick overview of collaborative efforts:

| Farm Initiative | Benefit |

|---|---|

| Integrated Pest Management | Reduces chemical use and promotes natural predators |

| Cover Cropping | Improves soil health and prevents erosion |

| Organic Certifications | Increases market value and consumer trust |

Future Outlook

As we conclude our journey inside the Paddy Processing Factory, we invite you to reflect on the intricate journey that transforms humble rice grains into the beloved staple found in kitchens around the world. From the rhythmic hum of machinery to the skillful hands of workers, every step in this process tells a story of dedication, innovation, and the seamless integration of technology with tradition.

The next time you savor a steaming bowl of rice, consider the journey it undertook—overcoming challenges, embracing advancements, and ultimately, nourishing countless lives. Understanding this journey not only deepens our appreciation for the food we consume but also connects us to the countless individuals behind its production.

As we step away from the factory’s bustling atmosphere and return to our daily lives, let us carry with us a newfound respect for the dedicated artisans and the processes that turn grains into nourishment. The journey from field to factory to bowl is more than a mere transformation of ingredients; it is a testament to human ingenuity and perseverance. Until our next exploration, may your meals be filled with gratitude for the stories woven into every bite.