In the heart of the countryside, where the golden fields sway with the breeze and the sun-kissed grains await their fate, lies a bustling hub of activity – a paddy processing plant. Here, the age-old tradition of harvesting rice is brought to life through modern technology and time-honored techniques. Join us on a journey from harvest to table as we delve into the inner workings of this fascinating world, where every grain tells a story of hard work, precision, and the timeless connection between man and nature.

The Journey of Rice from Field to Factory

Rice is a staple food for over half of the world’s population, and the journey it takes from field to factory is a fascinating process. At the paddy processing plant, the harvested rice undergoes a series of steps to transform it from raw grain to the familiar white rice we see on our plates. The first step in this journey is the cleaning and dehusking of the rice, where any impurities are removed and the outer husk is stripped away.

Next, the rice is polished to remove the bran layer, giving it that shiny, white appearance. After polishing, the rice is sorted by size and quality, ensuring that only the best grains make it to the final packaging stage. Once sorted, the rice is then packaged and ready to be distributed to stores and eventually to our tables, ready to be cooked and enjoyed.

State-of-the-Art Equipment and Technology in Paddy Processing

Within the walls of a modern paddy processing plant, cutting-edge equipment and technology are seamlessly integrated to streamline the journey from harvest to table. State-of-the-art machinery such as the high-capacity paddy husker and precision rice polisher work in harmony to deliver the highest quality rice grains to consumers around the world. Automated sorting systems utilize advanced sensors and algorithms to ensure that only the finest grains make it to the packaging stage.

At the heart of the processing plant, computerized control panels monitor every stage of production, optimizing efficiency and minimizing waste. The utilization of innovative drying techniques, such as infrared heating technology, reduces energy consumption and speeds up the drying process. With a focus on sustainability, the plant incorporates eco-friendly practices like water recycling systems and solar panels to lessen its environmental impact.

Efficient Practices for Maximum Yield and Quality

At our state-of-the-art paddy processing plant, we have implemented a range of efficient practices to ensure maximum yield and quality in our final products. From the moment the raw paddy arrives at our facility to when it is transformed into rice ready for the table, every step of the process is carefully monitored and optimized for the best results.

One key practice we follow is **precision milling**, where the paddy is milled to remove the husk and bran layers while retaining the valuable rice kernel. Our **automated sorting system** ensures that only the highest quality grains make it through the processing line, resulting in a final product that is uniform in size and free of impurities. To further enhance the quality of our rice, we also **polish** each grain to give it a shiny finish and improve its cooking characteristics.

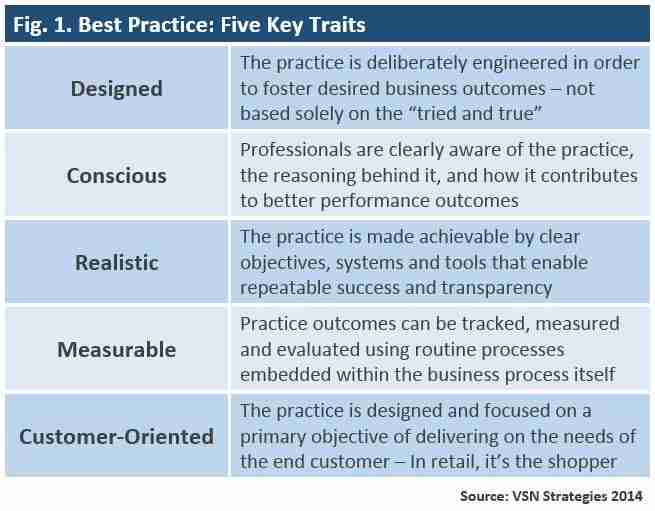

Best Practices for Storage and Distribution of Processed Rice

When it comes to storing and distributing processed rice, there are several best practices that can ensure the quality and freshness of the final product. One important practice is to store rice in a cool, dry place to prevent moisture buildup and potential mold growth. It is also crucial to keep rice away from direct sunlight to avoid exposure to heat, which can lead to the rice becoming stale.

Another important aspect of storage and distribution is proper packaging. Rice should be stored in airtight containers or bags to protect it from contamination and pests. Additionally, labeling packages with expiration dates can help ensure that older rice is used first, maintaining freshness and quality. By following these best practices, rice producers can ensure that their products reach consumers in optimal condition, providing a delicious and nutritious experience.

In Retrospect

As we wrap up our journey through the paddy processing plant, we hope you have gained a deeper understanding of the intricate process that brings rice from the fields to our tables. From the careful selection of grains to the meticulous sorting and packaging, each step plays a vital role in ensuring the quality and freshness of the final product. Next time you enjoy a bowl of rice, take a moment to appreciate the labor of love that goes into each grain. Thank you for joining us on this insightful journey from harvest to table.