In the heart of bustling markets and quiet rural landscapes, the humble grain of rice has long stood as a cornerstone of sustenance for billions around the globe. However, the journey from paddy to plate can often be fraught with inefficiencies that affect both producers and consumers alike. Enter the mini rice milling machine—a compact marvel of modern engineering poised to revolutionize the rice milling process. As agricultural traditions evolve in the face of growing demands and technological advancements, these machines offer a promising solution, unlocking newfound efficiency for farmers and small-scale producers. In this article, we delve into the rise of mini rice milling machines, exploring their design, benefits, and impact on the future of rice production. Join us as we navigate this transformative wave that is reshaping the rice industry, one grain at a time.

Understanding the Functionality of Mini Rice Milling Machines

Mini rice milling machines have revolutionized the agricultural sector by offering efficient processing solutions tailored for smaller-scale operations. These machines are designed with advanced technology that optimally mills rice, ensuring higher yield and quality. The compact design allows for easy transport and setup, making them ideal for farms and small processing units. Users can benefit from features like automatic separation of husk, bran, and polished rice, all while minimizing the manual labor typically associated with traditional milling methods. This advancement not only increases productivity but also enhances the overall quality of the final product, leading to better marketability.

Furthermore, the versatility of mini rice milling machines is notable. They can often handle various types of rice, ensuring that different varieties can be processed without issue. Additional benefits include:

- Energy Efficiency: Consumes less power than larger machines.

- Low Maintenance: Designed with durability in mind, requiring minimal upkeep.

- User-Friendly: Simple operation with minimal training required.

- Cost-Effective: Affordable investment for small businesses or individual farmers.

To better understand the efficiency of these machines, consider the following comparison of traditional versus mini rice milling machines:

| Feature | Traditional Milling | Mini Rice Milling Machine |

|---|---|---|

| Setup Time | Long | Short |

| Power Consumption | High | Low |

| Processing Speed | Variable | Consistent |

| Quality of Output | Variable | High |

With such features and advantages, mini rice milling machines are not just a trend; they represent a significant shift towards smarter and more sustainable agricultural practices.

The Economic Benefits of Transitioning to Mini Rice Milling Solutions

Small-scale farming and food production are increasingly winning the economic race due to the cost-effective nature of mini rice milling solutions. By reducing the overall production costs, these machines help smallholder farmers enhance their profit margins while simultaneously improving rice quality. This efficiency not only allows farmers to sell better-quality rice at competitive prices but also supports local economies. Potential benefits include:

- Lower operational costs: Reduced energy consumption and maintenance expenses.

- Increased productivity: Faster milling processes that save time and labor.

- Local job creation: Opportunities for employment in nearby communities.

- Direct market access: Ability for farmers to sell processed rice locally without intermediaries.

Moreover, transitioning to mini rice milling solutions can create a ripple effect across the entire agricultural sector. The investment in these machines positively influences supply chains and supports sustainable farming practices, leading to a healthier environment and improved food security. Here’s how:

| Factor | Impact |

|---|---|

| Reduction of Waste | Higher efficiency results in less paddy loss and better resource management. |

| Quality Control | Consistent quality boosts customer satisfaction and market demand. |

| Community Engagement | Empowers local farmers and encourages collaborative initiatives. |

As more farmers adopt these innovative milling technologies, the potential for stimulating rural economies and supporting sustainable practices becomes evident. Mini rice milling solutions not only ensure tailored processing options that cater to local needs but also foster the growth of resilient agricultural communities.

Streamlining Operations: Key Features to Look For

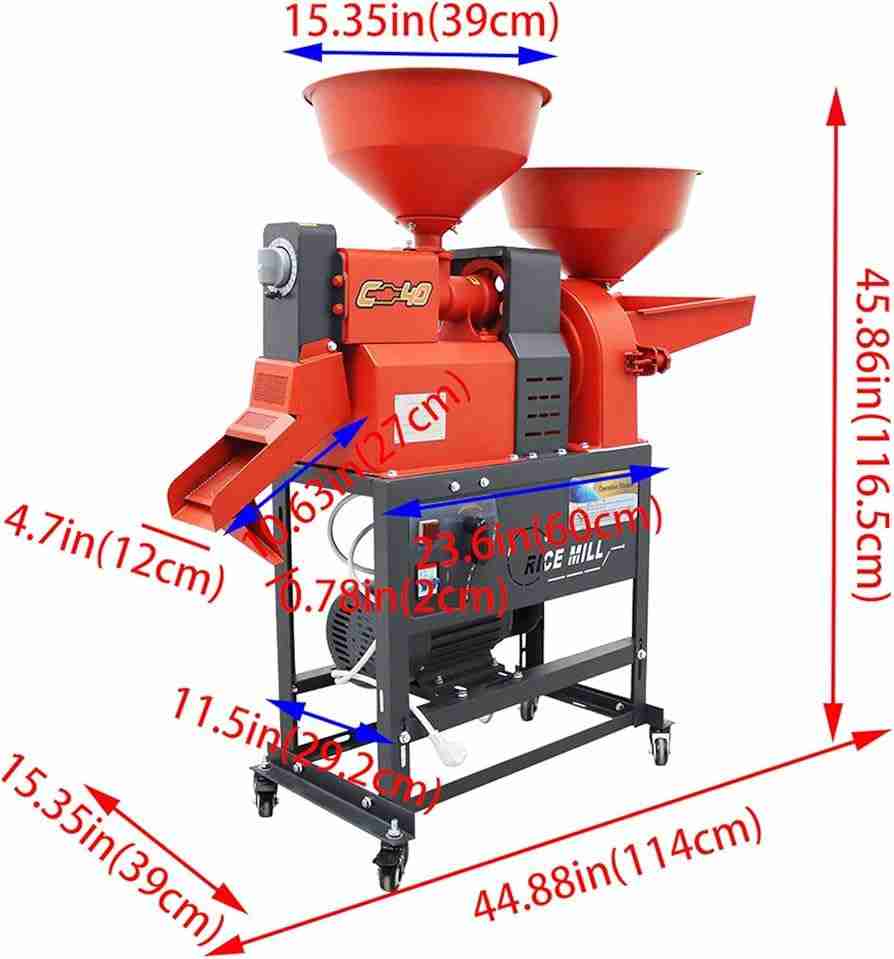

When it comes to enhancing the efficiency of rice milling operations, investing in a mini rice milling machine can prove transformative. Key features that elevate these machines beyond basic functionalities include their compact design, which is crucial for optimizing space, especially in smaller operations or urban settings. Additionally, look for integrated automation capabilities that reduce labor costs and minimize human error. The ability to set custom grinding levels allows for tailored production, offering flexibility for different grain types and textures. Moreover, machines equipped with energy-efficient motors contribute to lower operational costs without compromising on performance.

Another critical aspect to consider is the ease of maintenance. A mini rice milling machine that allows quick access to internal components for cleaning and repairs can drastically reduce downtime. Furthermore, innovations in processing technology—such as multifunctionality, which enables milling, polishing, and grading in one go—can save both time and resources. Enhanced safety features, like automatic shut-off mechanisms, are also essential to prevent accidents during operation. By focusing on these attributes, operators can ensure they select a machine that not only meets current demands but is also adaptable to future needs.

Maximizing Output: Tips for Optimal Use and Maintenance

To make the most of your mini rice milling machine, it’s essential to adhere to a routine of proper use and maintenance. First, familiarize yourself with the manufacturer’s guidelines regarding operation. Regular calibration ensures that the machine operates at its peak efficiency; this involves adjusting the settings based on the type of rice you are processing. Additionally, consider implementing the following practices to enhance performance:

- Regular Cleaning: Remove any debris or leftover grains after each use.

- Lubrication: Apply lubricant to moving parts as recommended to reduce friction and wear.

- Monitoring Temperature: Ensure the machine stays cool during operation to prevent overheating.

Furthermore, understanding the optimal settings for different rice varieties can significantly boost output. Each type of rice, from basmati to jasmine, may require slight adjustments in milling time and pressure. Keeping a detailed logbook of your operations can help identify patterns and areas for improvement. Here’s a helpful reference for common adjustments based on rice type:

| Rice Type | Milling Time (minutes) | Pressure Setting |

|---|---|---|

| Basmati | 10 | Medium |

| Jasmine | 12 | Low |

| Brown Rice | 15 | High |

By keeping these strategies in mind, users can ensure the longevity of their machinery, while still harnessing maximum output for business or personal use. Continuous monitoring and adjustment translate to consistent results, driving efficiency in operations.

Future Outlook

As we close the chapter on the remarkable evolution of mini rice milling machines, it becomes clear that these compact powerhouses are not just a trend; they represent a significant shift in the way we approach agricultural efficiency and food production. By harnessing advanced technology in a smaller, more accessible format, these machines empower farmers and entrepreneurs alike, democratizing the milling process and paving the way for sustainable practices.

The journey of the mini rice milling machine is a testament to human ingenuity, adaptability, and the endless quest for improvement. As we embrace this innovation, it’s essential to consider not just the immediate benefits but also the broader implications for communities and the environment. Whether you’re a seasoned professional or a curious newcomer, the rise of these machines invites us all to reflect on our roles in the agricultural landscape and to envision a future where efficiency and sustainability go hand in hand.

In this ongoing narrative of agricultural transformation, the mini rice milling machine stands as a beacon of possibility. As we continue to explore and innovate, one thing is certain: the grains of today will shape the fields of tomorrow.