In an increasingly fast-paced world, the quest for efficiency permeates every industry, and agriculture is no exception.Enter the mini rice mill combines—a game-changing innovation that promises to transform the way we approach rice production. As the backbone of sustenance for half of the global population,rice demands a nuanced understanding of both its cultivation and processing. mini rice mill combines symbolize a leap toward modernity, melding time-honored agricultural practices wiht cutting-edge technology. This article delves into the myriad ways these compact, multifunctional machines enhance efficiency in rice milling, from reducing labor costs to minimizing post-harvest loss, ultimately shining a light on their potential to shape the future of rice farming. Join us as we explore the remarkable features and benefits of mini rice mill combines, and examine how they are redefining productivity in agrarian communities around the world.

Exploring the Mechanics behind mini rice mill Combines

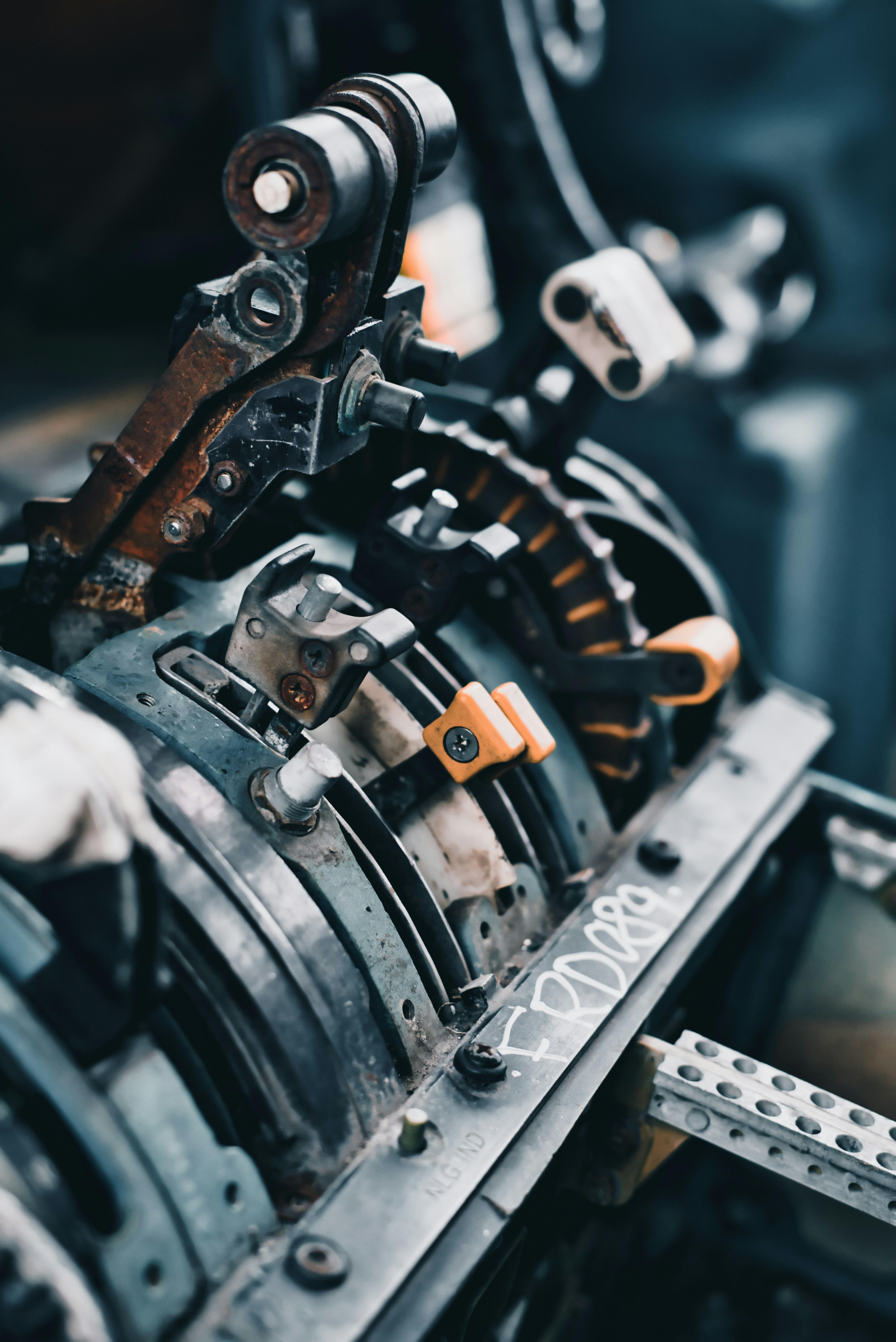

At the heart of mini rice mill combines lies a remarkable integration of technology and design that streamlines the rice milling process. These compact machines employ advanced engineering principles to efficiently transform paddy into polished rice.Key components such as the husker, separator, and rice polisher work in harmony to ensure minimal grain loss and optimal texture.The ability to operate in small-scale farms allows for a personalized approach to rice production, helping farmers retain quality while also reducing labor costs.

One of the most noteworthy features of mini rice mill combines is their energy-efficient design.By utilizing a single engine for multiple processes, these machines significantly cut down on fuel consumption compared to traditional methods. Additionally,the modular setup allows for easy maintenance and upgrades,ensuring durability and long-term functionality. To illustrate the benefits succinctly,consider the following table:

| Feature | Benefit |

|---|---|

| compact size | Suitable for small farms |

| Multi-functional | Reduces the need for multiple machines |

| Energy-efficient | Lower operating costs |

This blend of practicality and innovation positions mini rice mill combines as a game-changer in the agricultural landscape,empowering smallholder farmers to elevate productivity and profitability in the rice milling sector.

Key Benefits of mini rice mill Combines for Small-Scale Farmers

mini rice mill combines are revolutionizing the agricultural landscape for small-scale farmers, offering a multitude of advantages that significantly enhance operational efficiency. These compact machines simplify the rice production process by integrating multiple functions into one unit. Farmers can benefit from:

- Time Savings: the all-in-one design reduces the time spent on various milling stages, allowing farmers to process rice quickly and focus on other essential tasks.

- Cost-Effectiveness: By minimizing the need for multiple machines and labor, mini rice mill combines help lower production costs, making rice cultivation more financially viable.

- Increased Yield: These machines ensure higher output rates and better quality rice, contributing to improved profitability for farmers.

- Accessibility: Their small size and ease of use make these combines accessible to smallholder farmers who traditionally lack the resources for larger milling setups.

Additionally, mini rice mill combines play a crucial role in promoting sustainable agricultural practices. These machines reduce waste by efficiently utilizing raw rice, thereby supporting eco-kind farming methods. The integration of technology also encourages a transition to modern farming techniques. Here’s a table summarizing some key features:

| Feature | Benefit |

|---|---|

| Compact Design | Saves space and enhances portability. |

| Multi-Functionality | Combines harvesting, milling, and packaging in one unit. |

| User-Friendly Interface | easy operation for farmers with minimal technical skills. |

| Affordable Maintenance | Lower upkeep costs compared to larger machinery. |

Maximizing Productivity: Best Practices for Operating mini rice mill Combines

To achieve peak performance when utilizing mini rice mill combines, operational efficiency is paramount.Implementing a structured scheduling system enables mill operators to optimize their working hours. This not onyl minimizes downtime but also ensures that the combine works at its full potential during peak harvest periods. Operators should also prioritize regular maintenance to enhance the longevity and efficiency of the equipment. A systematic approach to maintenance can include:

- Daily inspections to check for wear and tear.

- Routine cleaning to prevent residue buildup.

- Timely servicing for critical components.

Moreover,training staff on effective operating techniques is crucial.Knowledgeable operators can make real-time adjustments to maximize output and reduce waste. integrating technology such as GPS systems for monitoring and tracking can greatly improve precision in milling processes. Below is a comparison of key operational factors that can enhance productivity:

| Factor | Impact on Productivity |

|---|---|

| Regular Maintenance | Increases machine efficiency and lifespan |

| Operator Training | enhances skillful handling and reduces errors |

| Technology Integration | Improves accuracy and data tracking |

Future Innovations in Mini Rice Milling Technology

The future of mini rice milling technology is poised for transformative innovations driven by advancements in automation, sustainable practices, and smart technology integration. With the global demand for rice increasing, manufacturers are focusing on creating machines that not only enhance productivity but also reduce waste and energy consumption. Key advancements include:

- Smart Sensors: Integration of AI and IoT technologies that monitor moisture levels, helping to optimize milling processes and enhance yield quality.

- Energy-Efficient Motors: development of high-efficiency motors that minimize electricity consumption while ensuring rapid milling times.

- Modular Designs: Innovations enabling easy upgrades and repairs, extending the lifespan and adaptability of mini rice mills.

Moreover,the introduction of bio-based materials in manufacturing these mini rice mills is encouraging a shift towards eco-friendly machines,reducing the carbon footprint associated with traditional milling processes. Emerging technologies such as 3D printing are also enabling more complex and efficient designs, leading to cost reductions and improved functionality. A look at potential benefits reveals:

| Innovation | Benefit |

|---|---|

| IoT Connectivity | Real-time data tracking for optimized workflow. |

| Automated Calibration | Consistent milling quality with minimal human intervention. |

| Compact Designs | Space-efficient solutions ideal for small-scale operations. |

The way Forward

As we draw the curtain on our exploration of mini rice mill combines,it’s clear that these innovative machines are transforming the landscape of rice milling. By marrying technology with traditional practices, they empower farmers and mill operators to achieve greater efficiency, reduce waste, and elevate the quality of their produce. As the world continues to grapple with the challenges of food security and sustainable agriculture, mini rice mill combines stand out as a beacon of promise—offering scalability and simplicity in a single, compact package. As we look to the future, embracing such advancements may not only enhance productivity but also nourish livelihoods and communities. The journey of rice milling is evolving, and at the heart of this evolution lies the enduring quest for efficiency and sustainability. Let us continue to celebrate and invest in such innovations that hold the potential to reshape our agricultural practices for generations to come.