Unlocking the secrets of maize milling is like peeling back the layers of a golden corn cob to reveal the intricate process that transforms it into the staple food of billions of people worldwide. In this article, we will delve into the world of maize milling, exploring the ancient techniques and modern innovations that have unlocked the full potential of this humble grain. Join us on a journey through the maize fields and milling machines as we uncover the hidden secrets that have been passed down through generations, shaping the way we grind, sift, and sift again to produce the flour that sustains us all.

Exploring the History and Significance of Maize Milling

Maize milling has a long and rich history, dating back thousands of years. The process of grinding maize into flour has been a staple in many cultures, serving as a fundamental element in their diets. From ancient civilizations to modern industrial processes, maize milling has played a significant role in shaping societies and economies.

Understanding the significance of maize milling involves delving into its cultural, social, and economic impact. The production of maize flour has not only provided sustenance for communities but has also been a source of livelihood for many. Additionally, the technological advancements in maize milling have revolutionized the way we process and consume this versatile grain. By , we can unlock the secrets behind this essential practice and appreciate its importance in our daily lives.

The Key Components and Processes of Maize Milling

Unlocking the Secrets of Maize Milling

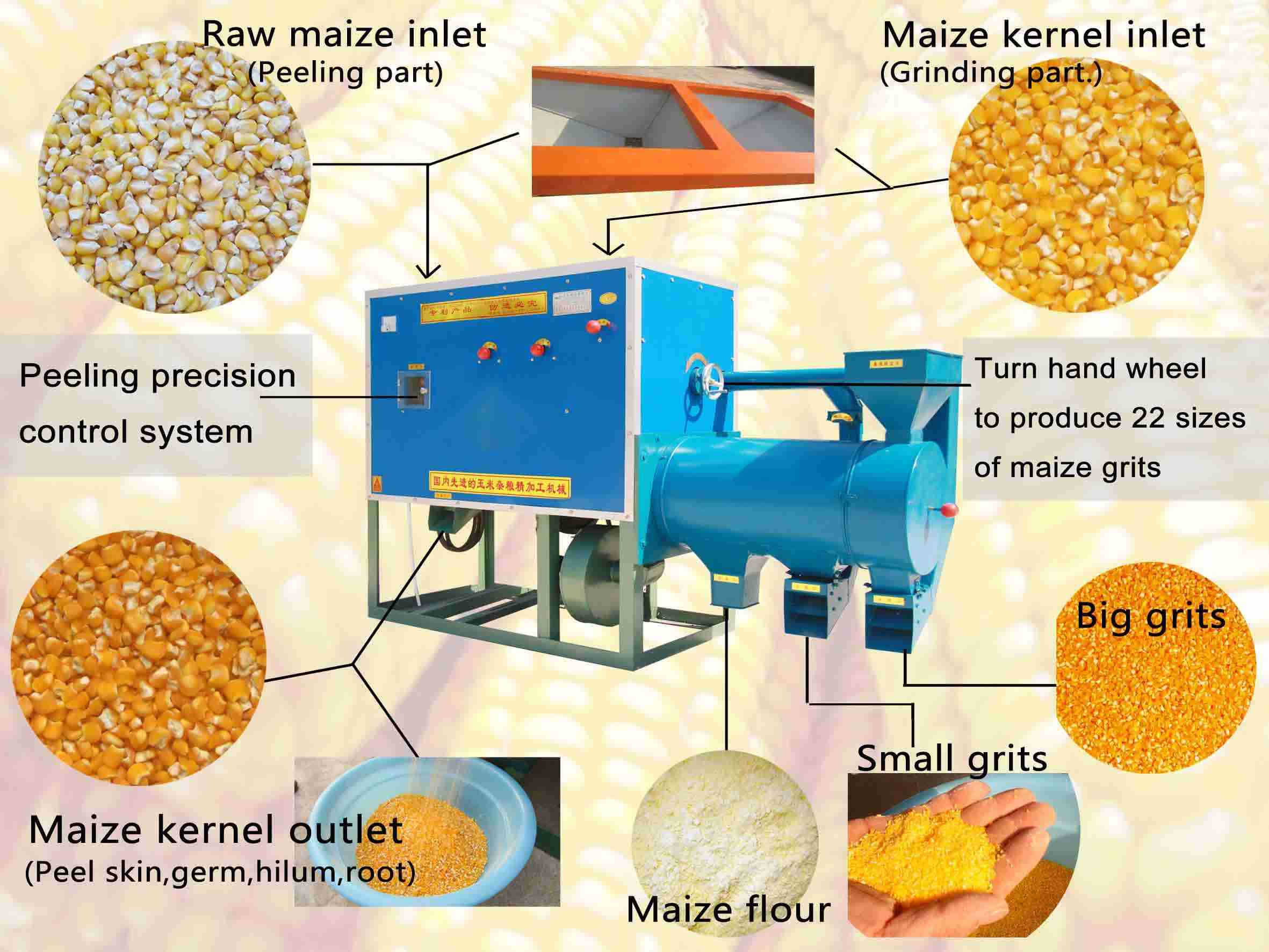

Maize milling involves a series of key components and processes that are essential for turning maize kernels into various products such as flour, meal, and grits. The main components of a maize milling process typically include:

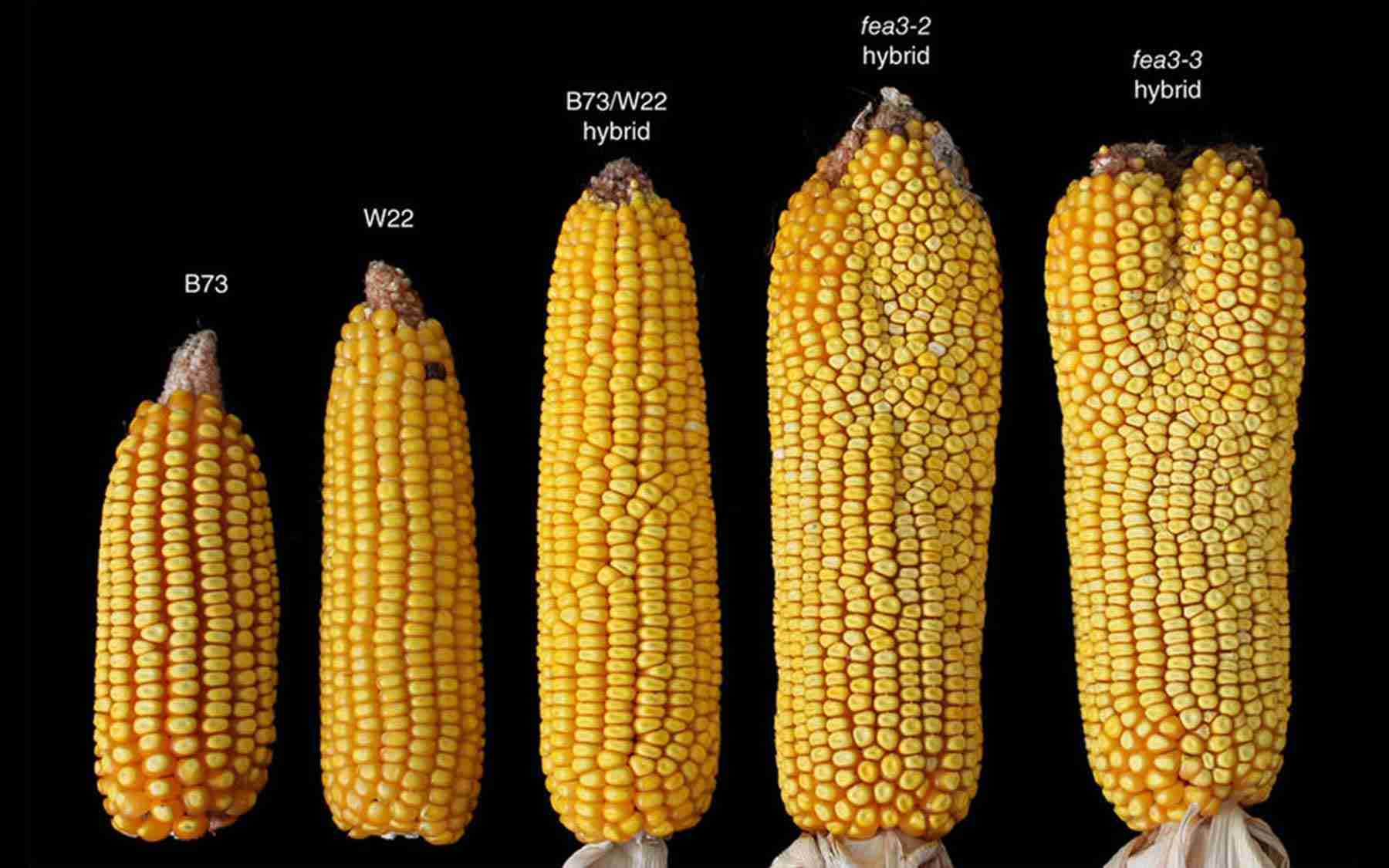

- Raw materials: Quality maize kernels are the starting point for any successful milling operation.

- Cleaning: The maize kernels are thoroughly cleaned to remove any impurities such as dust, stones, and other foreign matter.

- Conditioning: The cleaned maize is conditioned by adding water to achieve the desired moisture content for milling.

- Milling: The conditioned maize kernels are then ground into different particle sizes using various milling techniques.

- Sifting: The milled maize particles are sifted to separate the different products such as flour, meal, and grits.

These key components and processes work together seamlessly to produce high-quality maize products that are used in a variety of food products around the world. By understanding the intricacies of maize milling, millers can optimize their operations to meet the demands of the market and produce products that exceed customer expectations.

Enhancing Efficiency and Quality in Maize Milling Operations

When it comes to maize milling operations, efficiency and quality are key factors that every miller should prioritize. By unlocking the secrets of maize milling, millers can significantly improve their operations and deliver superior products to their customers. One of the most important secrets to enhance efficiency is investing in modern milling equipment that is designed to process maize efficiently and accurately.

Additionally, implementing proper maintenance practices and regular inspections can help prevent downtime and ensure consistent quality output. Another secret to improving maize milling operations is optimizing the milling process to minimize waste and maximize yield. By focusing on these key areas, millers can unlock the full potential of their maize milling operations and achieve unparalleled efficiency and quality.

Best Practices for Maximizing Maize Milling Productivity

When it comes to maximizing maize milling productivity, there are a few key best practices that can make a significant difference in the efficiency and output of your operation. One of the most important factors to consider is the quality of the maize being used. Using high-quality maize will result in a better final product with higher yields and better profits. Additionally, maintaining and regularly servicing your milling equipment is crucial to ensure optimal performance and prevent breakdowns that can negatively impact productivity.

Another best practice to consider is implementing proper cleaning and sorting procedures to remove any impurities or foreign materials from the maize before milling. This can help prevent contamination and ensure a higher quality end product. Additionally, optimizing the milling process itself by adjusting settings such as moisture content, grind size, and milling speed can help improve efficiency and maximize productivity. By focusing on these key areas, you can unlock the secrets of maize milling and achieve greater success in your operation.

Concluding Remarks

In conclusion, the intricate process of maize milling may seem like a mystery to some, but with the right knowledge and techniques, its secrets can be unlocked. By understanding the various components and methods involved in milling maize, we can appreciate the significance of this staple food and the skill required to produce it. So next time you enjoy a delicious cornmeal dish, remember the journey that maize has taken from field to flour, and the fascinating secrets of maize milling that have been revealed along the way.