Unlocking the Process: A Deep Dive into Maize Milling

In the heart of agriculture lies one of the world’s most versatile and essential grains: maize. From the golden fields of America to the vibrant markets of Africa, maize has woven itself into the fabric of countless cultures. But behind the scenes, a complex and meticulous process transforms this hardy crop into a staple ingredient that fuels economies and nourishes communities. Welcome to the world of maize milling—a journey that takes us from the hushed whispers of the harvest to the rhythmic clatter of the milling machine. In this article, we will unlock the intricate steps of maize milling, exploring the technologies, techniques, and traditions that converge to turn a simple grain into the foundation of countless culinary delights. Whether you are a food enthusiast, an agricultural expert, or simply curious about the journey of your everyday staples, join us as we delve into the fascinating process that powers an industry and sustains populations around the globe.

Understanding the Maize Milling Spectrum: From Grain to Flour

Maize milling is an intricate process marked by several distinct stages that transform the raw grain into fine flour. The journey begins with the careful selection of high-quality maize, which is then subjected to the first critical phase: cleaning. This step is essential to remove impurities such as stones, dirt, and other foreign materials that could affect the quality of the final product. Following this, the maize undergoes conditioning, where moisture is added to toughen the bran and soften the endosperm, preparing it for the milling process. The milling itself is a multifaceted operation involving both grinding and sieving to separate the maize into its component parts: flour, bran, and germ.

Once milled, the flour can be categorized based on its texture and purpose, ranging from coarse to finely ground options. The resulting flour plays a pivotal role in various culinary applications, providing the base for products such as tortillas, cornbread, and polenta. Understanding these classifications can be beneficial for suppliers, bakers, and consumers alike, ensuring the right type of flour is utilized for each recipe. Below is a brief overview of the flour types derived from maize milling:

| Flour Type | Texture | Common Uses |

|---|---|---|

| Coarse Flour | Rough | Polenta, Grits |

| Medium Flour | Granular | Tortillas, Muffins |

| Fine Flour | Soft | Cakes, Breads |

This transformation from grain to flour not only highlights the complex processes involved but also emphasizes the vital role of each stage in achieving the desired flour characteristics. Understanding this intricate milling spectrum allows enthusiasts and professionals alike to appreciate the artistry behind cooking and baking with maize while promoting the nutritional benefits it offers.

The Science Behind Efficient Milling Techniques and Equipment

In the world of maize milling, the efficiency of milling techniques and equipment is underpinned by a complex interplay of science and engineering principles. Understanding the physical and chemical properties of maize grains—such as moisture content, kernel hardness, and starch composition—can significantly influence the milling process. Techniques like dry milling and wet milling are employed based on these properties, each requiring specific equipment and parameters to optimize output and retain quality. Moreover, particle size reduction is a crucial factor; it affects not only the milling efficiency but also the final product’s characteristics. Adjusting variables such as feed rate and milling speed can enhance product yield and maintain quality while minimizing energy consumption.

To ensure effective milling, various types of equipment are utilized, each with distinct functions that collectively contribute to the process’s success. Key machinery includes:

- Roller mills: These are designed for grinding grains to a fine particle size.

- Impact mills: They utilize high-speed impact to break down grains efficiently.

- Pin mills: These create a shearing effect to achieve the desired texture.

- Separators: Essential for classifying the milling output based on particle size.

The integration of modern technology, such as automated controls and computerized monitoring systems, further boosts efficiency, enabling precise adjustments that adapt to variations in grain characteristics.

| Equipment Type | Function | Best Used For |

|---|---|---|

| Roller Mill | Grinding grains | Producing flour |

| Impact Mill | High-speed grinding | Coarse to fine particles |

| Pin Mill | Shearing and grinding | Uniform particle size |

| Separator | Classifying particles | Balancing texture |

Through the application of these technologies, maize milling can be finely tuned to maximize efficiency, allowing millers to unlock the full potential of their raw materials while ensuring sustainability and economic viability. The evolution of milling science continues to be at the forefront of achieving optimal results in the maize milling industry.

Quality Control Essentials: Ensuring Consistency in Maize Products

In the intricate landscape of maize milling, quality control stands as a pillar of consistency and excellence. By systematically monitoring every stage of the milling process, producers can significantly enhance the end product’s quality. Key aspects of quality control include:

- Raw Material Inspection: Regular tests on maize for moisture content, purity, and foreign materials ensure a high-quality start.

- Process Monitoring: Continuous observation of milling parameters such as temperature and pressure can prevent deviations that affect consistency.

- Final Product Testing: Rigorous quality checks on flour or cornmeal for texture, color, and flavor guarantee a product that meets industry standards.

To facilitate effective quality management, maintaining thorough records is essential. This practice not only aids in tracing the source of issues but also strengthens accountability across the production chain. Implementing a feedback loop where quality findings are reported to the relevant departments fosters a culture of continuous improvement. The table below summarizes critical quality indicators for maize products:

| Quality Indicator | Target Value |

|---|---|

| Moisture Content | 13-14% |

| Purity Level | 98%+ |

| Color Consistency | Uniform Yellow |

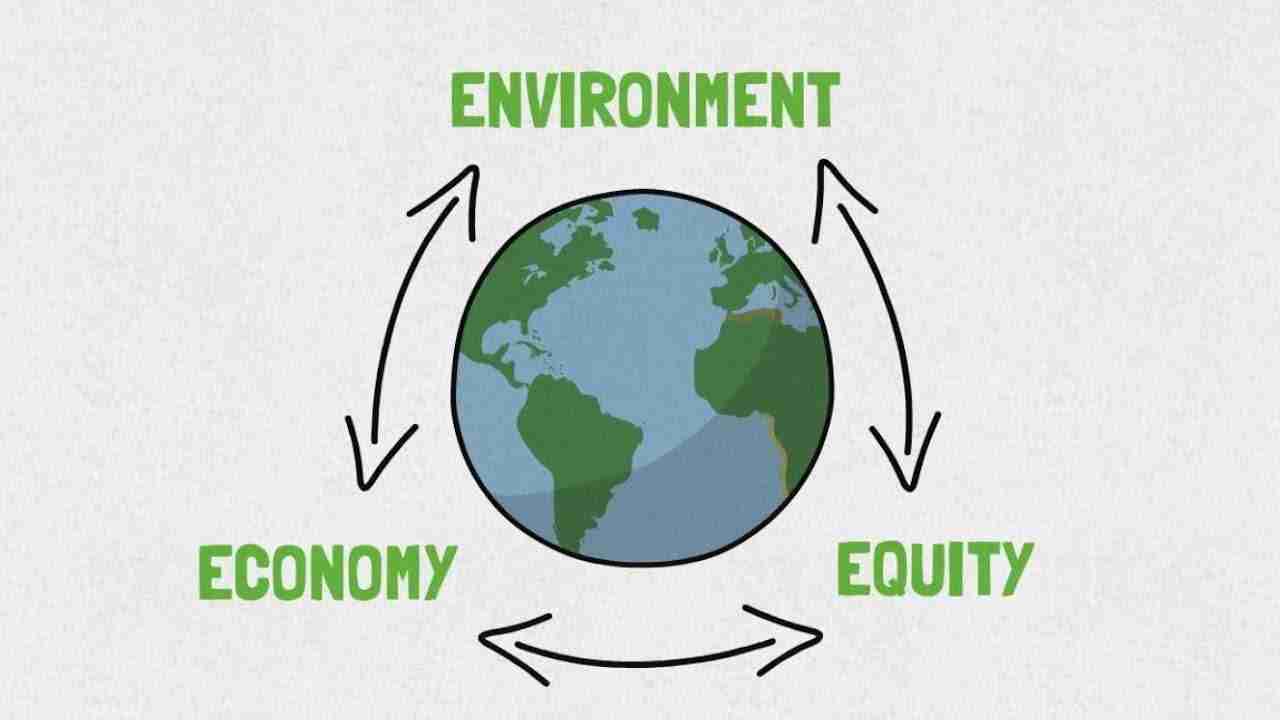

Sustainability in Maize Milling: Practices for a Greener Future

As the world gravitates towards sustainable practices, maize milling is no exception. The industry is increasingly adopting eco-friendly techniques to reduce its environmental footprint. Water conservation is paramount; modern milling facilities are re-engineering their systems to recycle water used in the processing stages, ensuring minimal waste. Additionally, energy-efficient machinery, equipped with variable speed drives and renewable energy sources, plays a vital role in reducing overall energy consumption. This shift not only lowers operational costs but also contributes positively to the environment by decreasing greenhouse gas emissions.

Furthermore, sustainable sourcing of raw materials is at the forefront of ethical practices in milling. By partnering with local farmers who adhere to environmentally friendly agricultural techniques, mills are supporting biodiversity and soil health. Transparency in the supply chain promotes responsible procurement, enhancing consumer trust. These practices are often measured and refined through careful monitoring, which can be summarized in the following table:

| Practice | Impact | Benefits |

|---|---|---|

| Water Recycling | Reduced water usage | Cost savings |

| Energy Efficiency | Lower carbon footprint | Long-term sustainability |

| Local Sourcing | Support for local economies | Enhanced transparency |

Future Outlook

As we draw the curtains on our exploration of maize milling, it’s clear that this intricate process is much more than just grinding grains. It represents a fusion of tradition and technology, where the age-old practices of our ancestors meet the innovations of modern engineering. From the selection of the finest maize to the precise techniques employed in milling, every step carries the potential to transform raw ingredients into a staple of diets around the world.

In this deep dive, we have uncovered the layers that make up the milling process, revealing the science and skill behind the creation of maize flour. We have seen how this fundamental grain serves not only as a vital food source but also as a catalyst for economies, cultures, and culinary artistry.

As the sun sets on our journey, we invite you to reflect on the vital role maize milling plays in our global landscape. Whether you’re a farmer, a miller, or a consumer, knowing the intricacies of this process equips you with a greater appreciation for the food on your plate. Unlocking this knowledge opens the door to a world where every bite is infused with history, innovation, and the promise of sustenance.

Thank you for joining us as we navigated the fascinating world of maize milling; until next time, may your understanding flourish as richly as the fields of golden maize.