In the world of agriculture, there is a fascinating and complex process that turns humble corn into a versatile and essential ingredient in our everyday lives. From the ancient techniques of grinding corn by hand to the modern industrial methods of producing corn derivatives, the art and science of corn processing have come a long way. Join us on a journey through the history, techniques, and innovations of corn processing, and discover how this simple grain holds the key to a myriad of products and possibilities.

Understanding the historical significance of corn processing

Corn processing has played a crucial role in the development of societies throughout history. Dating back to ancient civilizations such as the Maya and Aztecs, corn was a staple food source that provided sustenance and nutrients. The process of milling corn into various forms such as cornmeal, corn flour, and cornstarch was a labor-intensive task that required skill and precision. allows us to appreciate the art and science behind this essential food staple.

Through the centuries, corn processing techniques have evolved and adapted to meet the needs of changing times. From traditional stone grinding mills to modern industrial processing plants, the methods of extracting corn’s nutrients have become more efficient and sophisticated. The invention of corn processing machinery such as grain mills and corn shellers revolutionized the way corn was harvested and utilized. Today, corn processing not only provides food and sustenance but also serves as a foundation for various industries such as biofuels, livestock feed, and food additives.

Exploring the various methods of corn milling

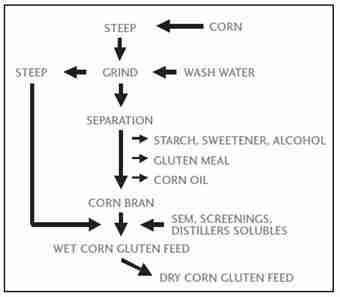

Corn milling is a fascinating process that combines both art and science. There are various methods used to mill corn, each with its own unique characteristics and advantages. One common method is dry milling, where corn kernels are ground into flour for food products like cornbread and tortillas. Wet milling, on the other hand, involves soaking the corn in water before processing it into products like corn syrup and ethanol. Each method requires precision and expertise to achieve the desired outcomes.

Other methods of corn milling include stone milling, which produces a coarser texture perfect for grits and polenta, and hammer milling, which is often used for animal feed. The choice of milling method can greatly impact the final product, influencing its flavor, texture, and nutritional content. Understanding the intricacies of each milling process is essential for producing high-quality corn products that meet consumer demands for taste and quality.

Examining the crucial role of enzymes in corn processing

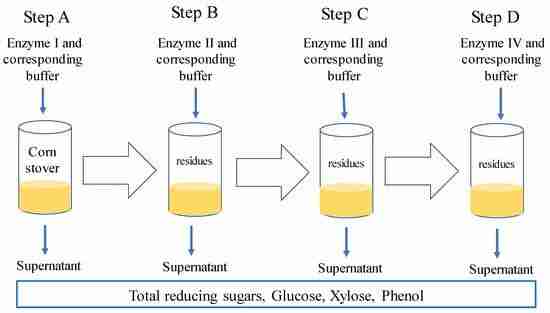

Enzymes play a crucial role in the complex process of turning corn into various products that we use every day. These biological catalysts help break down complex molecules in corn, such as starch, into simpler sugars that are essential for fermentation and other processes. Without enzymes, corn processing would be much slower and less efficient.

There are several key enzymes involved in corn processing, each with its specific function. Alpha-amylase helps break down starch into maltose, a type of sugar. Glucose isomerase then converts this maltose into high fructose corn syrup, which is commonly used as a sweetener in various food products. Another important enzyme is glucoamylase, which breaks down longer sugar chains into glucose, essential for producing ethanol and other industrial products.

Optimizing corn processing techniques for maximum yield

By combining traditional techniques with modern technology, corn processing can be optimized to achieve maximum yield. Farmers have long relied on tried and true methods to extract the most out of their corn harvest, but advancements in machinery and processes have opened up new possibilities for increasing efficiency and productivity. When corn processing is approached as both an art and a science, the results can be truly remarkable.

One key aspect of optimizing corn processing techniques is proper moisture management. By ensuring that corn is at the ideal moisture content before processing, farmers can reduce waste and improve overall yield. Additionally, utilizing specialized equipment such as grain dryers and moisture meters can help farmers accurately gauge moisture levels and make informed decisions. Embracing a holistic approach that takes into account both traditional wisdom and cutting-edge technology is essential for truly maximizing corn processing efficiency.

Wrapping Up

In conclusion, the art and science of corn processing is a dynamic and fascinating field that combines tradition with innovation. From ancient civilizations’ techniques to modern technological advancements, corn processing has evolved and continues to shape the way we consume this versatile crop. Whether it’s turning corn into food, fuel, or industrial products, the process is a delicate balance of artistry and scientific precision. By understanding the intricacies of corn processing, we can appreciate the skill and expertise that goes into bringing this humble grain to our plates and beyond. So next time you enjoy a corn-based dish or product, take a moment to contemplate the art and science behind it – it’s a journey worth exploring.