The Art and Science of Cereal Milling: A Grain Journey

In the world of food production, few processes are as fundamental yet intricate as cereal milling. From the golden fields of ripened grain to the bustling mills where the magic happens, the journey of cereal is a testament to both artistry and precision. Imagine the rustling of wheat in the breeze, the rhythmic hum of machinery, and the transformation of humble grains into the flour that forms the backbone of countless culinary creations. This article invites you to explore the fascinating interplay between tradition and technology in cereal milling—a journey that not only shapes our food but also reflects the innovation and dedication behind each grain. As we delve into the methods, machinery, and meticulous techniques involved, we’ll uncover the secrets that turn grain into the versatile ingredients we often take for granted, revealing the hidden artistry that defines this critical phase of food production. Join us as we embark on this exploration of the art and science woven into every handful of milled grain.

Exploring the Anatomy of Grains and Their Milling Potential

Understanding the structure of grains is paramount to mastering the milling process. At their core, grains consist of three primary components: the bran, the endosperm, and the germ. The bran, serving as the protective outer layer, is rich in fiber and essential nutrients, while the endosperm provides the bulk of the grain’s energy content in the form of carbohydrates. The germ, although minimal in size, is a powerhouse of vitamins and healthy fats, containing the genetic material necessary for a new plant. Analyzing these components not only reveals the nutritional potential of each grain but also how they can be transformed through milling into flours of varying textures and utilizations.

Each grain type exhibits unique characteristics that influence its milling potential and subsequent applications. For instance, the hard red wheat is celebrated for its high protein content, making it ideal for bread flour, while soft white wheat is preferred for pastries and cakes due to its lower protein level. Here’s a quick overview of some common grains and their key attributes:

| Grain Type | Protein Content | Common Uses |

|---|---|---|

| Hard Red Wheat | 12-15% | Bread, Pizza Dough |

| Soft White Wheat | 8-10% | Cakes, Pastries |

| Durum Wheat | 13-15% | Pasta, Semolina |

| Barley | 10-12% | Soups, Malt |

| Rye | 10-12% | Bread, Crackers |

In the world of milling, these distinctions are crucial in determining the right processing methods to unlock a grain’s fullest potential. Factors such as moisture content, hardness, and the milling technique employed can drastically affect the final product’s quality. Understanding these intricate details paves the way for innovation in flour production, allowing millers to cater to specific culinary needs while promoting the diverse flavors and nutritional benefits that grains have to offer.

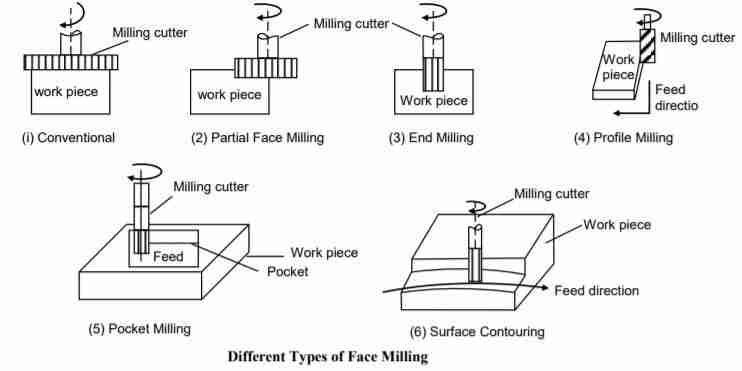

Understanding the Milling Processes: Techniques and Technologies

The journey of cereal milling embodies a harmonious blend of art and science, where traditional techniques meet modern innovations to transform raw grains into versatile food products. Whole grain milling, often celebrated for its nutritional richness, utilizes methods such as stone grinding and roller milling. Stone grinding involves using pairs of granite stones to crush grains slowly, preserving the kernel’s nutrient integrity. In contrast, roller milling operates on a system of precision steel rollers that can be finely adjusted, allowing millers to achieve specific particle sizes and textures. This method is often preferred for its efficiency and ability to produce uniformly refined flour suitable for numerous culinary applications.

On the technological side, automation and innovative machinery have revolutionized the milling process. Many mills now employ computerized systems that monitor grain quality and moisture levels, ensuring consistency in the final product. These advancements include techniques such as air classification and extrusion, which enhance the milling process by segregating various components of the grain for targeted use. An important aspect of this transformation is the growing interest in organic and sustainable milling practices, which aim to reduce the ecological footprint of cereal production. Through these evolving methods and technologies, the cereal milling industry continues to adapt, ensuring it meets both consumer demands and sustainability goals.

| Technique | Description | Benefits |

|---|---|---|

| Stone Grinding | Ancient method using granite stones. | Preserves nutrients; richer flavor. |

| Roller Milling | Modern technique using steel rollers. | High efficiency; consistent texture. |

| Air Classification | Separates grain components by weight. | Utilizes finer grades; greater versatility. |

| Extrusion | Processes grains under heat and pressure. | Enhances digestibility; new product forms. |

Quality Control in Cereal Milling: Ensuring Consistency and Safety

Within the realm of cereal milling, quality control acts as both a guardian and a compass, guiding producers toward achieving consistently high standards in their final products. This intricate process involves the rigorous testing of raw materials, cutting-edge technological interventions, and meticulous attention to detail. The goal is to ensure that every batch adheres to strict specifications regarding texture, nutritional content, and food safety. Critical checkpoints along the milling journey might include:

- Grain Selection: Choosing the right varieties of grains that meet the desired quality standards.

- Moisture Analysis: Assessing moisture levels to prevent spoilage and maintain product integrity.

- Pest Inspection: Ensuring that grains remain free from infestations and foreign materials.

- Laboratory Testing: Conducting regular tests for protein content, gluten strength, and other vital attributes.

Moreover, implementing sound quality control practices not only enhances the safety of cereal products but also builds consumer trust. The integration of advanced technologies, such as automated sensors and real-time monitoring systems, revolutionizes how mills operate, making it easier to identify discrepancies and rectify them promptly. In a constantly evolving market, millers are also harnessing data analytics to predict trends and adjust processes accordingly. The significance of these efforts can be summarized in the following table:

| Quality Control Aspect | Purpose |

|---|---|

| Raw Material Testing | To ensure the best grains are sourced for milling. |

| Milling Process Monitoring | To guarantee consistent particle size and flour quality. |

| Final Product Testing | To confirm adherence to safety standards and specifications. |

Sustainable Practices in Grain Milling: Balancing Tradition and Innovation

Grain milling has long been a dance between the hands of tradition and the pulse of innovation. As millers strive to produce high-quality flour while minimizing environmental impact, sustainable practices are emerging as a vital aspect of the industry. By integrating renewable energy sources, such as solar and wind power, facilities are beginning to reduce their carbon footprint significantly. Additionally, initiatives that focus on water conservation, recycling, and waste management not only fulfill ethical responsibilities but also enhance operational efficiency. The following practices highlight the commitment to sustainability:

- Utilizing modern milling technologies to reduce energy consumption.

- Implementing zero-waste policies through byproduct recycling.

- Adopting organic farming practices in sourcing raw grains.

- Engaging in local sourcing to minimize transportation emissions.

The blend of traditional techniques with modern advancements creates a unique landscape for grain milling. For instance, many mills are now exploring new cultivar varieties that are more resistant to pests and diseases, ultimately leading to a reduced need for chemical treatments. This symbiosis of past and present not only achieves efficiency but also fosters a sustainable relationship with the land. Consider the following table that illustrates the benefits of these innovative practices:

| Practice | Benefits |

|---|---|

| Renewable Energy | Reduces dependency on fossil fuels. |

| Water Conservation | Minimizes water use and protects local waterways. |

| Crop Rotation | Enhances soil health and promotes biodiversity. |

| Local Sourcing | Supports local economies and reduces emissions. |

Future Outlook

As we conclude our exploration into “The Art and Science of Cereal Milling: A Grain Journey,” we find ourselves at the intersection of tradition and innovation. This intricate process, meticulously honed over centuries, blends age-old techniques with cutting-edge technology, transforming humble grains into the nutritious staples that grace our tables.

From the rhythmic hum of the millstones to the precision of modern machinery, every step of milling is a testament to human ingenuity and the enduring significance of agriculture. Each grain carries a story—a narrative of the soil, sun, and seasonal rhythms that forged it—and through milling, we unlock its potential, nourishing both body and spirit.

As we reflect on this journey, may we appreciate not only the bread on our plates but also the delicate artistry and scientific prowess that brought it there. In understanding the complexities of cereal milling, we cultivate a deeper respect for our food and the hands that create it, inviting us to cherish each bite as a celebration of craft, culture, and connection. Indeed, the journey of grain is far from over; it continues to evolve, shaping our diets and futures in ways yet to be imagined.