The Art and Science of Cereal Milling: A Detailed Exploration

In the ever-evolving landscape of food production, few processes blend artistry and scientific precision quite like cereal milling. From the golden fields that cradle ripened grains to the rhythmic hum of machinery in modern mills, this intricate craft has shaped civilizations for centuries. At first glance, milling may appear as a straightforward task—grains ground to flour—but the reality is a harmonious convergence of age-old techniques and cutting-edge technology. This article endeavors to peel back the layers of this fascinating domain, revealing not only the meticulous methods and innovative advancements that define milling today, but also the cultural significance and nutritional implications of one of humanity’s oldest practices. Join us on a journey through the heart of cereal milling, where tradition meets innovation, and discover the nuanced interplay that transforms humble grains into foundational foodstuffs.

Understanding the Milling Process from Grain to Flour

The journey from grain to flour is a fascinating blend of traditional craftsmanship and cutting-edge technology. At its core, milling transforms raw grains, such as wheat, corn, or barley, into the fine flour that is essential for countless culinary applications. The process begins with cleaning, where impurities like dust, stones, and other foreign materials are meticulously removed to ensure quality. This is followed by conditioning, a crucial step that involves adjusting the moisture content of the grain. By treating the grain with a precise amount of water and allowing it to rest, millers enhance the wheat’s milling qualities, making it easier to separate the bran and germ from the endosperm during grinding.

- Grinding: The heart of the milling process, where the cleaned and conditioned grain is ground into flour.

- Sieving: This step separates flour from bran and other particles, ensuring a consistent texture.

- Packaging: Final flour products are then packaged for distribution, ready to be transformed into delicious baked goods.

Throughout the milling process, various techniques are employed to achieve the desired flour characteristics, which include factors like texture, color, and protein content. Different milling systems, such as stone milling and roller milling, offer distinct qualities and are chosen based on the final product’s use. For example, stone milling preserves the natural nutrients and flavor of the whole grain, while roller milling produces finer flour. The table below summarizes these milling methods:

| Milling Method | Characteristics | Typical Uses |

|---|---|---|

| Stone Milling | Retains nutrients, rustic texture | Artisan breads, whole grain flours |

| Roller Milling | Fine texture, efficient, less bran | Commercial breads, pastries, cakes |

Nutritional Considerations in Cereal Milling Techniques

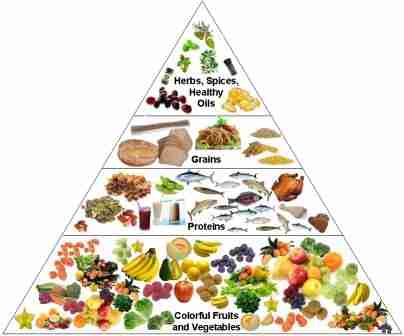

Understanding the intricate relationship between milling techniques and the nutritional profile of cereals is paramount for achieving optimal health benefits. Milling not only influences the texture and flavor of the final product, but it also plays a crucial role in determining the nutrient availability from various grains. Different milling processes can lead to varying degrees of nutrient retention or loss, thus impacting the overall dietary value of the flour produced. For instance, while whole grain milling retains the bran, germ, and endosperm, resulting in a higher fiber and micronutrient content, refined milling often strips these essential components, thereby diminishing the grain’s nutritional potential.

Moreover, the choice of milling technique can significantly affect the bioavailability of essential nutrients. Factors such as particle size, moisture content, and the presence of additives can either enhance or inhibit nutrient absorption in the human body. To better understand this relationship, here is a comparison of typical nutrients in whole grain versus refined grain products:

| Nutrient | Whole Grain | Refined Grain |

|---|---|---|

| Fiber | 3-6 g per serving | 0.5-2 g per serving |

| Iron | 1.5-3 mg per serving | 0.5-1 mg per serving (often fortified) |

| B Vitamins | High levels (e.g., B1, B3, B6) | Lower levels (often fortified) |

Beyond the nutritional content, the milling process can also influence the glycemic index (GI) of cereal products. Coarse milling methods often yield grains with larger particle sizes, which may contribute to lower GI values and a slower release of glucose into the bloodstream. In contrast, finely milled flours tend to have a higher GI, potentially leading to spikes in blood sugar. Thus, incorporating diverse milling techniques and educating consumers about their impacts on nutrition can empower healthier choices, underscoring the importance of these considerations in the cereal milling industry.

Innovations in Milling Technology and Their Impact on Quality

The advancements in milling technology have reshaped the landscape of cereal processing, significantly enhancing both efficiency and product quality. Roller mills, which replaced traditional stone mills, enable better control over particle size through precise adjustments, contributing to a more consistent flour texture. Additionally, the integration of computerized systems allows mill operators to monitor real-time data on moisture content and granulation, ensuring superior quality control. The impact of these innovations is evident in the resulting flour, characterized by improved baking performance, nutritional retention, and overall product integrity.

Furthermore, the introduction of environmentally friendly milling techniques has also made a considerable difference. Techniques such as cold milling, which uses lower temperatures during grain processing, help preserve essential nutrients and enzymes that might otherwise be lost in conventional milling methods. Notably, cleaner milling processes generate less waste and energy consumption, maximizing sustainability. The table below outlines some key innovations and their benefits:

| Innovation | Benefit |

|---|---|

| Roller Mills | Consistent particle size |

| Computerized Monitoring | Enhanced quality control |

| Cold Milling | Preserves nutrients |

| Eco-Friendly Techniques | Reduced waste and energy use |

Sustainable Practices in the Cereal Milling Industry

In recent years, the cereal milling industry has increasingly prioritized sustainability, recognizing its vital role in addressing environmental challenges. Innovative milling technologies play a crucial role in minimizing energy consumption and reducing waste. Key practices that exemplify this commitment include:

- Water Conservation: Implementing closed-loop water systems to reduce usage and recycle water within the process.

- Energy-Efficient Machinery: Upgrading to energy-efficient milling equipment to decrease the carbon footprint associated with production.

- Sourcing Sustainable Raw Materials: Partnering with farmers who practice sustainable agriculture, ensuring a responsible supply chain that promotes biodiversity.

Moreover, the adoption of waste reduction strategies in cereal milling enhances sustainability. Milling byproducts, such as bran and germ, can be repurposed into high-value products like animal feed or nutritional supplements. This creates a circular economy that not only aids in reducing landfill waste but also maximizes resource utilization. The following table highlights some significant impacts of sustainable practices in the milling sector:

| Practice | Environmental Benefit | Economic Impact |

|---|---|---|

| Water Recycling | Reduces freshwater usage | Lower operational costs |

| Energy System Optimization | Decreases carbon emissions | Increases energy savings |

| Utilization of Byproducts | Minimizes waste generation | Generates additional revenue streams |

The Way Forward

As we conclude our detailed exploration of the art and science of cereal milling, it’s clear that this meticulous process is a symphony of tradition and innovation. Beneath the surface of seemingly simple grains lies a complex interplay of mechanical precision and culinary creativity. The transformation of raw cereal into flour or meal is not merely utilitarian; it is a dance of chemistry, engineering, and time-honored techniques that have evolved across cultures and centuries.

Understanding the nuances of milling not only enhances our appreciation for the diverse array of food products derived from grains but also enlightens us about the intricate relationship between agriculture and gastronomy. With advancements in technology and increased awareness of nutritional quality, the industry is poised for further evolution, ensuring that cereal milling remains at the forefront of food science.

As you reflect on the journey from field to flour, consider the remarkable processes that bring your morning cereal to the table. Whether you are a home cook, a professional baker, or simply a curious foodie, the world of milling offers endless avenues for exploration and appreciation. The next time you savor that first crunch of your favorite breakfast, remember the artistry that goes into every kernel and the science that makes it possible. In the realm of cereal milling, the journey is as rich as the products it yields, inviting us all to take a closer look at the foundations of our daily sustenance.