Grain to Grain: The Art and Science of Cereal Milling

In the heart of agrarian landscapes, where golden fields stretch toward the horizon, an age-old transformation unfolds—one that has been central to human civilization for millennia. The journey from grain to grain is not merely a passage of raw material to nourishment; it is an intricate dance of art and science that defines the very essence of cereal milling. This multifaceted process combines the rhythmic cadence of machinery with the meticulous craftsmanship of millers, who breathe life into humble grains, unlocking their potential for our daily sustenance. As we delve into the world of cereal milling, we will explore the historical roots, the technological innovations, and the sensory pleasures that emerge from this vital industry, revealing the hidden complexities behind the flour that fills our kitchens and the cereals that fuel our families. Join us as we uncover the delicate balance of tradition and modernity that sustains this essential craft, transforming nature’s bounty into the staple foods we often take for granted.

The Journey from Harvest to Flour: Understanding the Cereal Milling Process

The journey from the field to the mill is a captivating transformation, one that blends both nature’s bounty and human ingenuity. The process begins with the harvest, where ripe grain is collected, often embodying the best of the season’s labor. Once gathered, the grain must undergo initial cleaning to remove impurities such as dirt, stones, and other unwanted materials. This step is crucial for ensuring the quality of the final product. Following cleaning, the grain is conditioned by adding moisture to achieve the ideal level for milling. This preparation optimizes the grain for grinding, affecting the texture and structure of the flour produced.

As the conditioned grain enters the milling phase, it is subjected to a series of precise mechanical actions designed to break it down into flour. The milling process typically involves multiple stages, which can be summarized as follows:

- Breaking: The grain is cracked into smaller pieces.

- Sifting: The cracked grain passes through screens to separate fine and coarse particles.

- Grinding: Smaller fragments are finely ground, producing various flour grades.

During this transformation, different milling techniques, such as stone milling or roller milling, may be employed to achieve unique flour textures. To visualize the journey, the table below highlights the key stages within the milling process:

| Stage | Description |

|---|---|

| Harvest | Collecting mature grain from the fields |

| Cleaning | Removing foreign materials from the grain |

| Conditioning | Adding moisture for optimal grinding |

| Milling | Grinding and processing the grain into flour |

Through this intricate process, what begins as simple grain is transformed into a versatile and essential ingredient, ready to be used in a variety of culinary creations. The art of cereal milling embodies a profound respect for both the grain and the craftsmanship required to bring it to life in the form of flour.

Precision in Milling Techniques: Balancing Artistry and Mechanization

Within the realm of cereal milling, precise techniques serve as the backbone for transforming raw grains into the finely crafted products that grace our tables. The delicate balance between artistry and mechanization reveals itself through a carefully orchestrated combination of traditional methods and modern technology. Stones once ruled the milling process, capturing an essence of craftsmanship that remains appreciated today. Yet, the advent of roller mills has ushered in an era of increased efficiency, allowing millers to achieve particle sizes that meet exacting standards without sacrificing quality. The resulting flour is a reflection of both the grain’s innate characteristics and the dexterity of the machinery employed in its processing.

To fully comprehend the symbiosis between technical precision and artistic flair, one must consider the following characteristics that distinguish successful milling practices:

- Moisture Control: Maintaining optimal moisture levels is essential for achieving the desired grain texture.

- Grain Selection: Premium quality grains lead to better milling outcomes, underscoring the importance of sourcing.

- Temperature Management: Controlling heat during milling preserves the grain’s natural oils and flavors.

Moreover, integrating modern technology introduces innovative methods such as laser sorting and automated monitoring systems that refine the milling process. These advancements not only enhance productivity but also assure consistent quality across production runs. As skilled operators embrace these tools, it becomes clear that the journey from grain to flour is a nuanced blend of timeless traditions and cutting-edge precision.

| Factor | Artistry Aspect | Mechanization Aspect |

|---|---|---|

| Grinding Technique | Traditional stone milling craftsmanship | Modern roller mills for uniformity |

| Quality Control | Hand inspection for unique textures | Automated quality sensors for consistency |

| Flour Type | Creative blends for artisanal products | Standardized flours for commercial use |

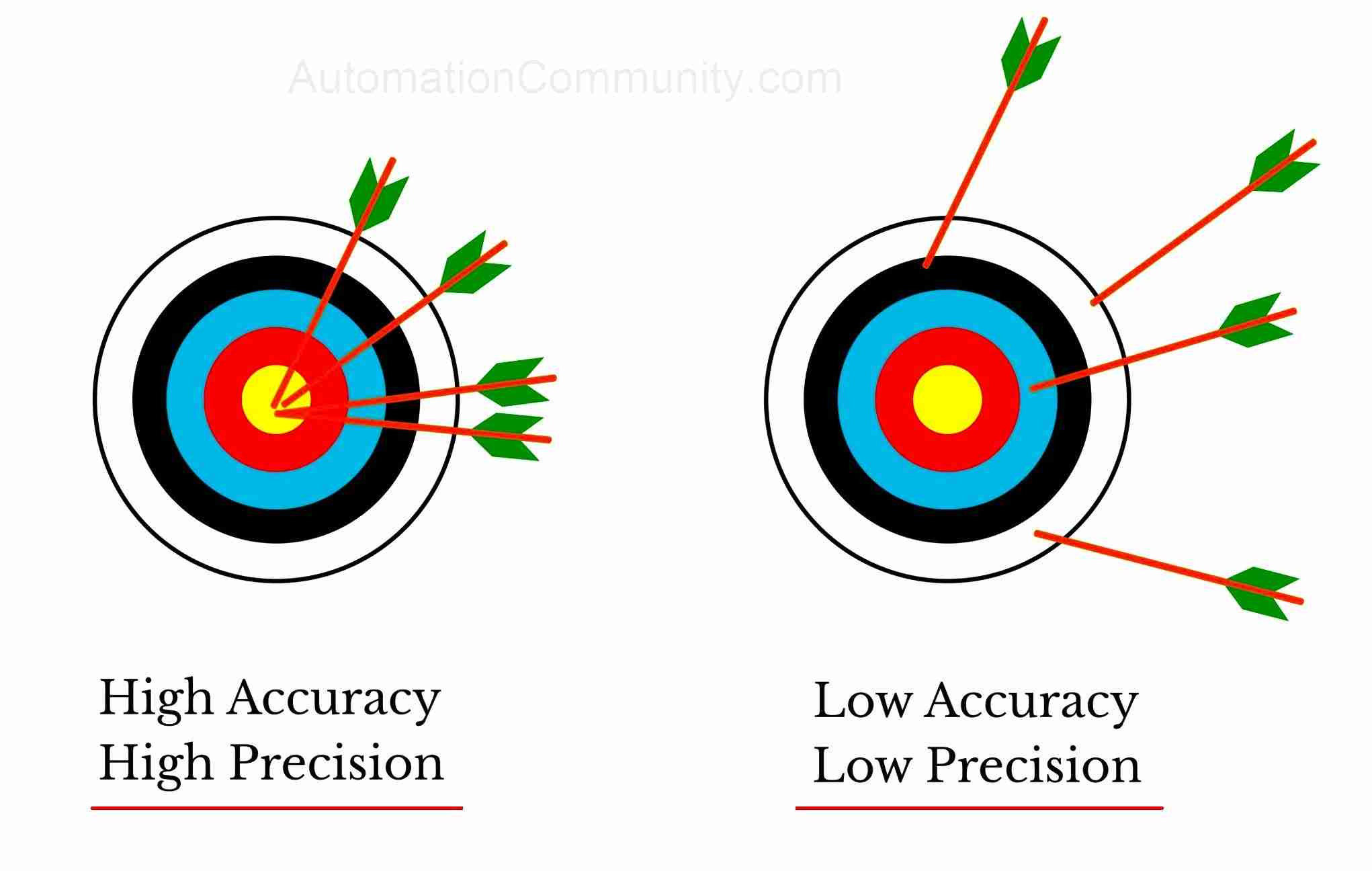

Quality Control in Grain Processing: Ensuring Consistency and Safety

In the intricate world of cereal milling, quality control stands as the linchpin for achieving both consistency and safety in the final product. Several key measures ensure that every batch of grain is processed to meet the high standards expected by consumers and regulatory bodies. Visual inspections play a crucial role, as operators examine the raw grains for signs of pest infestation or spoilage before processing begins. Following this, lab testing becomes essential. The grain is often evaluated for moisture content, protein levels, and contaminant presence, using cutting-edge technology to guarantee results that meet established quality benchmarks.

To further enhance the quality assurance process, mills often adopt a systematic approach incorporating both preventative and corrective strategies. This can include regular maintenance of milling equipment to reduce contamination risks and employing sensory evaluation techniques to ascertain the flavor and texture profiles of the cereal products. A transparent documentation system tracks every stage of production, ensuring accountability and traceability. Utilizing a combination of modern technologies and traditional methods, cereal mills strive to uphold the highest standards of quality control, ensuring that the grains consistently deliver not only on taste but also on safety.

Sustainable Practices in the Milling Industry: Innovating for a Greener Future

The milling industry has undergone a transformative journey towards sustainable practices, emphasizing innovations that significantly reduce environmental impact while enhancing product quality. Millers are increasingly turning to renewable energy sources such as solar and wind power to operate their facilities. These shifts not only diminish reliance on fossil fuels but also lower operational costs in the long run. Additionally, technologies such as energy-efficient machinery and waste management systems are being implemented, allowing for the recycling of materials and the minimization of waste. This commitment to sustainability extends to sourcing practices, where local grain procurement reduces transportation emissions and supports regional economies.

Furthermore, the integration of advanced water conservation techniques and the utilization of biodegradable packaging illustrate the milling industry’s dedication to protecting natural resources. To facilitate this shift, companies are investing in research and development focused on creating innovative solutions that bolster efficiency and sustainability. The chart below provides a snapshot of common sustainable practices adopted in modern mills:

| Practice | Description |

|---|---|

| Renewable Energy Usage | Implementing solar panels and wind turbines to power mills. |

| Water Conservation | Recycling water used in milling processes. |

| Biodegradable Packaging | Switching to materials that decompose naturally. |

| Local Sourcing | Purchasing grains from nearby farms to reduce carbon footprint. |

The Way Forward

As we conclude our journey through the intricate world of cereal milling, it becomes clear that this age-old craft is a harmonious blend of art and science. From the golden fields where grains are nurtured to the precise machinery that transforms them into versatile flours, each step of the milling process is a testament to human ingenuity and respect for nature.

The next time you sprinkle flour into your mixing bowl or savor the aroma of freshly baked bread, take a moment to appreciate the rich tapestry woven from grain to grain. It is a journey marked by tradition and innovation, where every granule tells a story of labor, love, and the pursuit of perfection.

In an era where sustainability and quality are paramount, the cereal milling industry stands at a crossroads, embracing the challenge of delivering nutritious and flavorful products while caring for the planet. As we turn the page on this exploration, we invite you to reflect on the grains that fuel our lives and the remarkable process that brings them to our tables. After all, in every bite we take, we partake in the legacy of an ancient practice transformed by the modern age.