In the heart of every loaf of bread, every delicate pastry, and every bowl of comforting porridge lies an intricate journey that begins long before the first bite. This journey, rooted in the age-old practice of milling, transforms humble grains into the fine flour that is foundational to our daily sustenance. “Grain to Flour: The Art and Science of Cereal Milling” invites readers to explore the delicate balance of tradition and innovation that defines this essential process. From the rhythmic whir of grinding stones to the precise calibrations of modern milling technology, we delve into the rich tapestry of techniques that have evolved over millennia. Join us as we uncover the artistry behind the transformation of raw grains into versatile flours, and the science that ensures they serve as the building blocks of our culinary creations. In unraveling this intricate process, we celebrate not only the grains themselves but also the millers who, through their craft, weave a connection between nature and nourishment.

Understanding the Milling Process: Transforming Grain into Flour

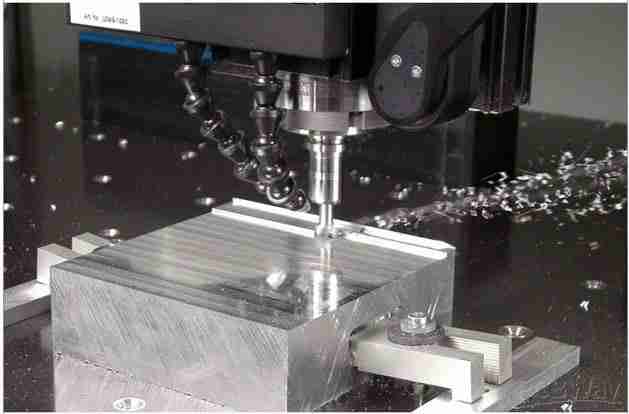

The milling process is a sophisticated dance between art and science, transforming harvested grains into a versatile ingredient that lies at the heart of many culinary traditions. At its core, milling involves multiple stages, each designed to achieve a specific goal while preserving the grain’s inherent qualities. The journey begins with cleaning, where grains are thoroughly sifted and sorted to remove impurities. Following this, conditioning ensures that the grains retain optimal moisture levels, making them easier to grind. The actual grinding stage employs various types of mills, such as roller or stone mills, each imparting unique characteristics to the flour.

Throughout these stages, several factors influence the final product, including the grain variety, milling technique, and end product requirements. Flour produced from hard wheat, for instance, is well-suited for bread making due to its high protein content, while softer varieties yield perfect pastries. The milling process culminates with the sifting of flour to achieve the desired fineness and consistency. To visually summarize these stages, the following table outlines essential milling processes:

| Stage | Description |

|---|---|

| Cleaning | Removing impurities and foreign materials. |

| Conditioning | Adjusting moisture content for optimal milling. |

| Grinding | Reducing grain to flour using various milling techniques. |

| Sifting | Separating flour by fineness and achieving consistency. |

This intricate dance of elements ensures that each batch of flour meets the diverse needs of bakers and chefs, allowing for boundless creativity in the kitchen. From the rich, nutty flour of whole grains to the light, airy texture of finely milled white flour, understanding these processes provides valuable insight into the culinary foundations we often take for granted.

The Role of Grain Selection in Quality Flour Production

In the intricate dance of milling, the variety of grains chosen serves as the foundation for high-quality flour, heavily influencing the end product’s texture, flavor, and baking performance. Quality flour production hinges on selecting grains that align with the desired characteristics of the final product. For instance, hard wheat types are rich in gluten, making them ideal for bread and pasta, while soft wheat varieties are perfect for cakes and pastries due to their lower gluten content. Each grain contributes distinct properties that dictate whether the flour is suitable for artisan sourdough or a delicate sponge cake.

The process of grain selection remains an art, combined with the science of understanding grain composition. Factors influencing grain choice include:

- Grain variety: Determines protein content and gluten strength.

- Harvest conditions: Affects moisture levels and grain integrity.

- Storage methods: Influences freshness and flavor retention.

Additionally, the milling process itself must harmonize with the selected grains to maximize their potential. For example, a coarser grind may enhance rustic bread but compromise the fluffiness of pastries. Here, one must consider the interaction between the grain’s natural properties and the desired flour qualities—a true testament to the synergy of art and science in cereal milling.

| Grain Type | Protein Content | Best Uses |

|---|---|---|

| Hard Red Wheat | 12-14% | Bread, Pasta |

| Soft White Wheat | 9-11% | Cakes, Pastries |

| Durum Wheat | 13-15% | Pasta, Couscous |

Technological Innovations in Cereal Milling: Enhancing Efficiency and Consistency

The world of cereal milling has undergone a significant transformation thanks to groundbreaking technological innovations. Modern milling processes now utilize advanced machinery equipped with precision sensors and automated controls, enabling millers to achieve improved efficiency and ensure consistent product quality. These innovations have streamlined the milling process, making it possible to monitor and adjust parameters in real time. Techniques such as digital milling, smart automation, and advanced analytics have emerged as key components in this evolution, allowing for faster processing times and reduced waste in the production of flour.

Additionally, the integration of sustainable practices into milling processes highlights a commitment to environmental stewardship. Innovations such as energy-efficient milling equipment and water reclamation systems demonstrate the industry’s focus on reducing its carbon footprint while maintaining high production standards. Companies are increasingly investing in biotechnology to enhance grain quality and modification techniques to improve yield and nutritional value. Innovations also extend to software solutions that optimize supply chain logistics, ensuring that the grains are processed and distributed promptly. This synergy of technology and traditional methods marks a new era in cereal milling, where efficiency and consistency are paramount.

Exploring Sustainable Practices in Flour Milling for a Greener Future

The transformation of grain into flour is not merely a mechanical process; it is a delicate dance between tradition and innovation. In recent years, flour milling has adapted to the pressing need for sustainability, resulting in environmentally friendly practices that minimize waste and energy consumption. One pivotal approach is the investment in energy-efficient milling technologies that reduce electricity use while maintaining high output quality. Milling facilities are increasingly employing renewable energy sources, such as solar or wind power, which not only lowers carbon emissions but also often proves more cost-effective in the long run. Furthermore, the use of recycled water systems in milling operations significantly lessens the demand for fresh water, demonstrating a strong commitment to resource conservation.

Alongside technological advancements, sustainability in flour milling also embraces the circular economy, where by-products of the milling process are re-utilized rather than discarded. For instance, bran and germ, commonly extracted during milling, can be redirected for use in nutraceuticals or as feed components in livestock farming, promoting a zero-waste initiative. Additionally, many mills are partnering with local farmers to source grains that are grown using organic farming practices, which not only supports local economies but also encourages biodiversity. A shift to labeling that educates consumers about the sustainability of their flour products can further drive this initiative, creating a consumer base that is informed and more supportive of eco-conscious mills.

Insights and Conclusions

As we conclude our exploration of “Grain to Flour: The Art and Science of Cereal Milling,” it becomes clear that this transformative journey is more than mere machinery and methods—it’s a symphony composed of time-honored traditions and innovative techniques, seamlessly blending the practical with the poetic. Each kernel, carefully cultivated, tells a story of the earth from which it springs, while the miller’s expertise reveals the potential locked within.

From the farmers nourishing the fields to the artisans refining their craft, every step in the milling process upholds a legacy that bridges generations. The dance of grains as they morph into flour carries a significance that transcends the kitchen, feeding not just our bodies, but also our culture and community.

As we turn our attention to the flour that enriches our loaves, pastries, and everyday meals, let us appreciate the intricate dance of nature and technology that brings it to our tables. We invite you to reflect on the journey your daily bread underwent, to celebrate the art and science behind it, and to understand that every bite is a testament to the enduring relationship between humanity and the nourishing grains of the earth.