From Grain to Grist: The Journey of Maize Milling Explained

In the heart of every cornfield lies a story waiting to be told—a journey that begins with a simple seed and unfolds through the processes of growth, harvest, and transformation. Maize, often referred to as corn, is not just a staple food; it is a cornerstone of culture and economy across the globe. As we delve into the intricate world of maize milling, we will unravel the fascinating transformation of this humble grain into vibrant grist, the finely ground product that serves as the foundation for countless culinary creations. Join us as we explore the stages of maize milling, from its origin on the farm to its final role in the kitchen, revealing the science and artistry behind this essential process.

Understanding the Maize Lifecycle from Field to Mill

Harvested maize undergoes a meticulous process before it reaches the mill, with each stage playing a crucial role in maintaining the quality of the grain. The journey begins in the field, where careful attention is paid to factors like soil health, water availability, and pest management, ensuring that the maize grows optimally. Once harvested, the maize is cleaned to remove impurities, such as dirt and debris. After cleaning, it proceeds to the drying stage, where moisture content is carefully managed. Excess moisture can lead to spoilage and affects milling quality. The key steps include:

- Soil Preparation: Ensuring nutrient-rich soil for better yield.

- Harvesting: Timing the harvest for peak grain maturity.

- Cleaning: Removing unwanted elements from the grain.

- Drying: Achieving optimal moisture levels for storage.

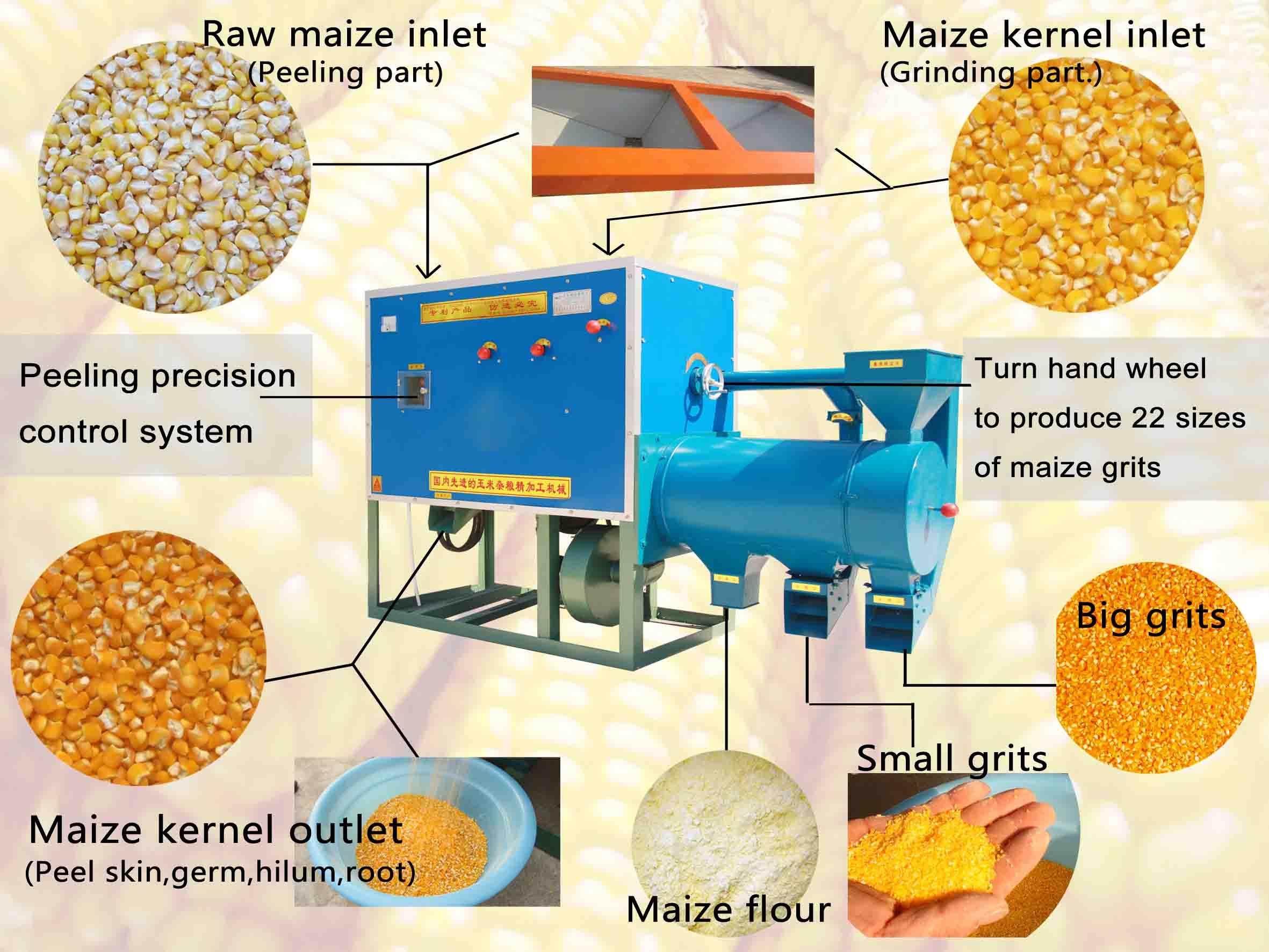

Once the maize is dried and stored properly, it is ready for the milling stage, where it is transformed into grist, the basis for myriad food products. The milling process involves several sophisticated methods designed to increase efficiency while preserving the integrity of the grain. Through grinding, sifting, and separation techniques, the maize is transformed into various forms—meal, flour, or grits. Quality control checks are essential at this stage to ensure consistency in texture and flavor. The milling process can be broken down into:

| Step | Description |

|---|---|

| Grinding | Reducing whole kernels into smaller particles. |

| Sifting | Separating flour from larger particles. |

| Quality Control | Ensuring uniformity and absence of contaminants. |

The Art and Science of Maize Milling Techniques

Milling maize is both an art and a science, where the convergence of technology and tradition shapes the final product. The journey begins with careful selection of high-quality maize kernels, which are the foundation of any milling process. Once harvested, the maize undergoes a series of steps that include cleaning, drying, and conditioning to ensure optimal milling performance. This preparatory phase is crucial, as it removes impurities and adjusts moisture content, ultimately affecting the grinding efficiency and flour quality. The milling itself can be accomplished through various methods, each producing distinct textures and flavors. Common techniques include:

- Stone milling: A traditional method that retains the grain’s nutrients and flavors.

- Hammer milling: Utilizes rapidly rotating blades to produce a fine flour, often used for commercial products.

- Roller milling: Employs a series of rollers to create a very fine flour, commonly used in large-scale operations.

Each milling technique affects not only the texture of the flour but also its flavor profile and nutritional value. For example, stone milling preserves the bran and germ, yielding whole-grain flour rich in fiber and nutrients, while roller milling produces a finer, more consistent product ideal for baking. Additionally, technology, such as sifting and grading, plays a vital role in achieving the desired end result. By grading the flour based on particle size, mills can cater to diverse culinary needs, thereby enhancing the versatility of maize flour in various recipes.

| Milling Technique | Texture | Nutritional Value |

|---|---|---|

| Stone Milling | Coarse and gritty | High in fiber and nutrients |

| Hammer Milling | Fine and fluffy | Variable, depending on grain type |

| Roller Milling | Very fine and smooth | Lower fiber content, refined |

Optimizing Flour Quality: Best Practices for Mill Operators

Mill operators play a crucial role in enhancing flour quality through effective practices that ensure consistency and superior product output. To start with, it’s essential to maintain optimal moisture content in maize grains, ideally between 13% and 14%. This helps in achieving a desirable milling efficiency. Regular monitoring can prevent spoilage and ensure that the grains are in the best condition for milling. Additionally, implementing a rigorous cleaning protocol is vital to eliminate foreign materials that can negatively impact flour quality. This includes thorough screenings and de-stoning of the grains prior to milling.

Furthermore, adjusting the milling parameters based on the grain quality is critical. Operators should consider the following factors to optimize the process:

- Roller Configuration: Select the right size and arrangement of rollers to achieve the desired particle size.

- Grinding Techniques: Utilize a combination of impact and shear grinding to improve flour texture.

- Temperature Control: Maintain appropriate temperatures during milling to prevent the denaturing of gluten.

In addition to the above, conducting regular quality assurance tests throughout the milling process ensures that the flour meets industry standards. Key tests include:

| Test Type | Purpose |

|---|---|

| Moisture Content | Determines the grain’s readiness for milling |

| Color Analysis | Checks for consistency in flour color |

| Gluten Strength | Assesses the flour’s baking performance |

Sustainability in Maize Processing: Innovations and Recommendations

In the quest to enhance sustainability within maize processing, innovators are turning to cutting-edge technologies and best practices that minimize waste and energy use. One promising avenue is the adoption of biodegradable packaging made from corn starch, which not only helps reduce plastic pollution but also supports the circular economy. Additionally, the implementation of energy-efficient milling machines plays a crucial role in decreasing the carbon footprint associated with maize production. Such advancements allow processors to achieve greater operational efficiency while producing higher-quality grist.

Furthermore, embracing waste valorization strategies can transform by-products into valuable resources. For instance, the husks and germ from maize can be processed into animal feed or biofuel, creating a closed-loop system that benefits both the economy and the environment. To aid in decision-making, a simplified comparison of various processing methods can provide insights into the potential impacts of sustainability efforts:

| Processing Method | Energy Consumption | Waste Generation | Sustainability Score |

|---|---|---|---|

| Traditional Milling | High | Moderate | 3/10 |

| Modern, Energy-efficient Milling | Low | Low | 8/10 |

| Integrated Bioprocessing | Moderate | Very Low | 9/10 |

It’s clear that by prioritizing innovative practices and technologies, the maize milling industry can move towards more sustainable operations. By recognizing the synergy between efficiency and environmental stewardship, stakeholders can create a more resilient sector that benefits everyone from farmers to consumers.

Future Outlook

As we conclude our exploration of the intricate journey from grain to grist, it’s clear that maize milling is much more than a mere transformation of raw material into a refined product. It is a confluence of science, tradition, and innovation, where centuries of agricultural heritage meet modern milling techniques.

Whether you’re a farmer tending to your fields, a miller perfecting your craft, or a consumer appreciating the final product on your plate, each step in this process reflects the dedication and expertise that goes into making maize a staple in many diets around the world.

From the sun-soaked fields of vibrant maize to the bustling mills that bring grain to life, every detail matters in this journey. As you take your next bite of cornmeal or enjoy a warm tortilla, remember the rich narrative behind your food—stories of hard work, sustainability, and the intricate dance between nature and technology.

Thank you for joining us on this enlightening voyage through the world of maize milling. We hope it inspires a deeper appreciation for the elements that shape our culinary experiences and encourages an ongoing dialogue about the importance of understanding the origins of what we consume.