In the vibrant tapestry of culinary traditions, few ingredients hold as much versatility and significance as maize. This humble grain, revered by countless cultures around the globe, transforms from a simple seed into a foundational element in diverse cuisines. Yet, the journey of maize from field to flour is a nuanced process, rich with history, craftsmanship, and innovation. In this article, we delve into the art of maize milling, an age-old practice that not only preserves the essence of this golden grain but also unveils the intricate techniques that have been refined over generations. Join us as we explore the stages of milling, the science behind the grind, and the impact of this process on the flavors and textures of the foods we cherish. Discover how the transformation of maize into flour is not merely a mechanical operation but a celebration of tradition, sustainability, and culinary creativity.

Understanding the Journey: The Path of Maize from Field to Flour

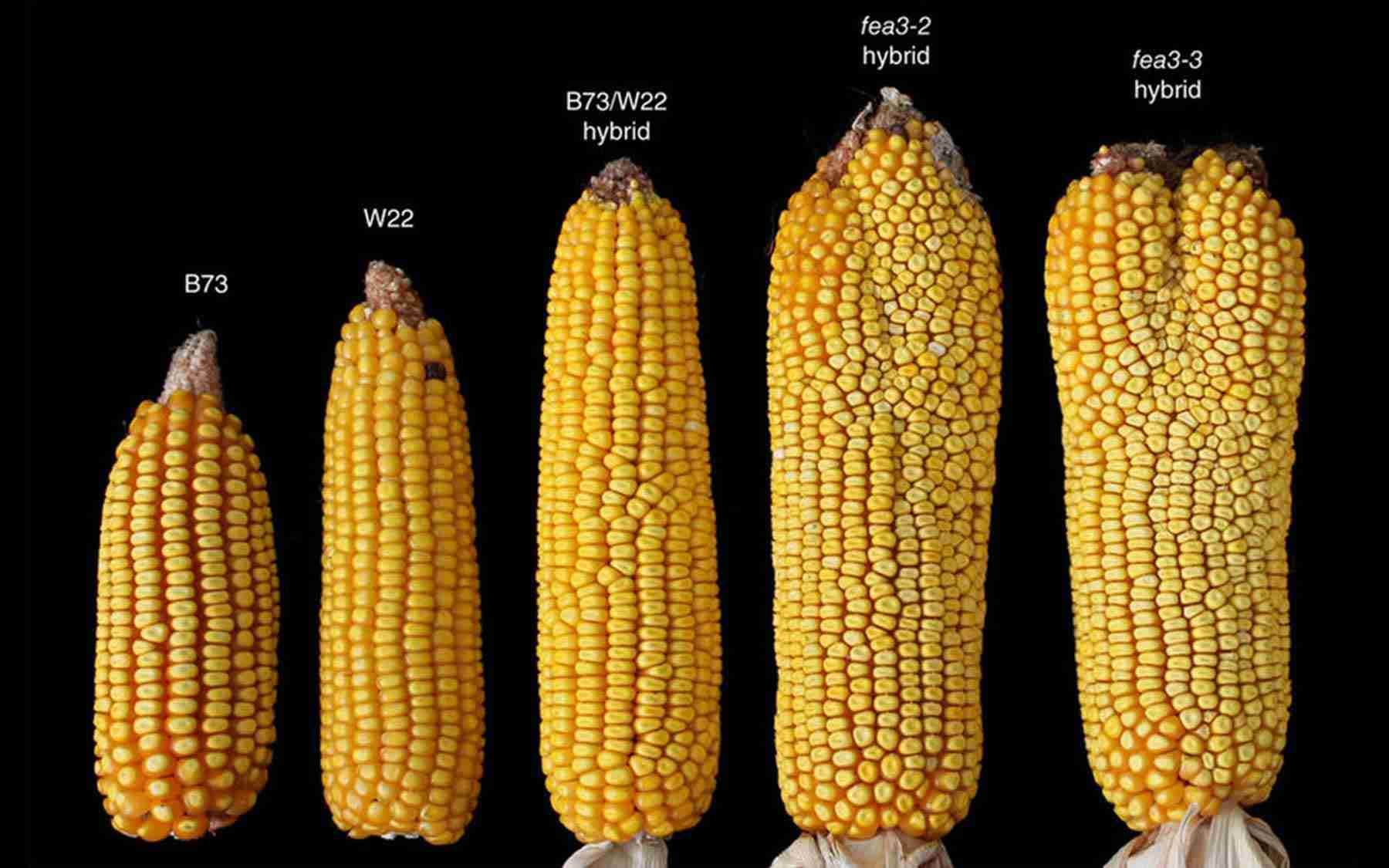

The journey of maize from the golden fields to the fine flour is a testament to both agricultural expertise and artisanal craftsmanship. At the beginning of this transformation lies the harvest, where plump ears of maize are picked at their peak ripeness. Each kernel, swollen with nutrients, has a story to tell—stories of the soil, the sun, and the rain. After harvesting, the grains undergo cleaning, where unwanted debris and impurities are removed, ensuring that only the best kernels make their way to the milling process. This essential step sets the stage for the subsequent transformations that bring out the rich flavors and textures of maize.

Next comes the milling process, characterized by several stages that convert whole grains into versatile flour. The kernels are subjected to dry milling, where they are cracked open, separating the endosperm from the germ and bran. This yields a range of products, from fine flour to coarse meal, all depending on the desired texture. Below is a simplified breakdown of the milling products:

| Milling Product | Texture | Common Uses |

|---|---|---|

| Fine Maize Flour | Silky | Baking, Tortillas |

| Coarse Meal | Grainy | Polenta, Grits |

| Maize Grits | Chunky | Breakfast Dishes |

After milling, the flour is often enriched with additional nutrients, enhancing its dietary value. Storage methods are also critical at this stage, as the freshly milled flour must be kept in optimal conditions to maintain its quality and flavor. This meticulous journey from field to flour unfolds a world rich in tradition, wisdom, and the artful mastery of farmers and millers alike.

Essential Equipment: Tools of the Trade in Maize Milling

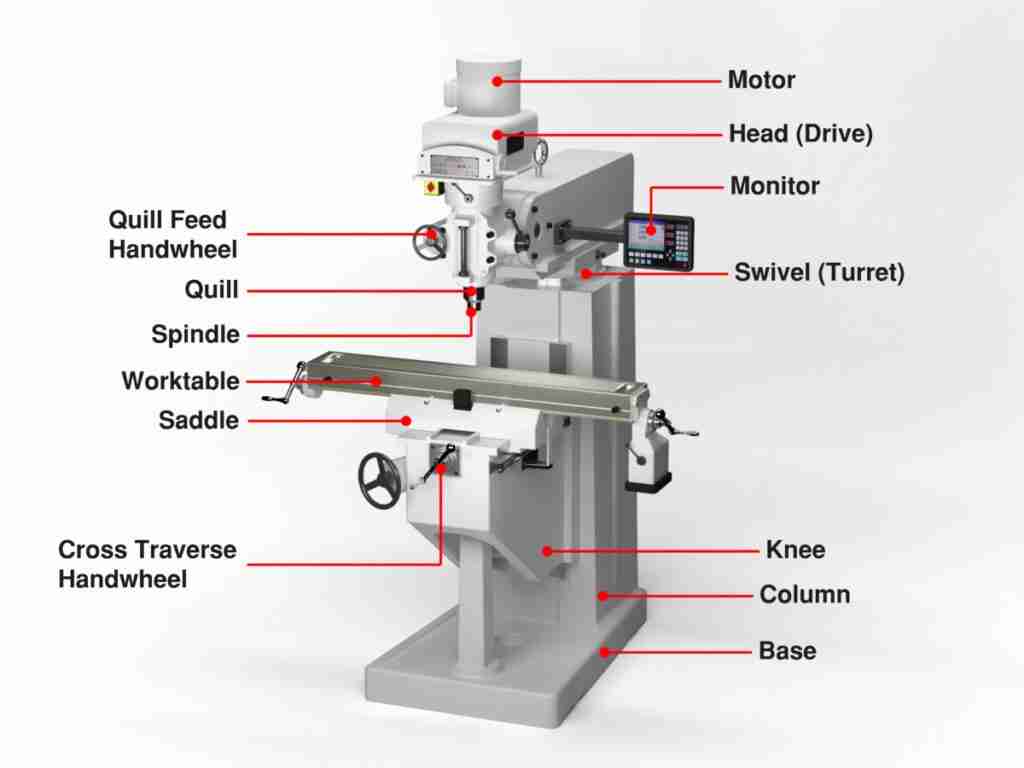

To embark on the journey from grain to flour, one must harness a variety of essential tools, each tailored to the unique requirements of the maize milling process. Milling machines serve as the heart of this operation, transforming whole grains into fine flour through a series of mechanical processes. Key types of milling machines include hammer mills, known for their high-speed impact on grains, and roller mills, which utilize the crushing action of two rotating cylindrical rollers to achieve a finer, more uniform flour. Additionally, sifting machines play a crucial role in ensuring the consistency and quality of the final product by removing any coarse particles and bran, thus refining the flour to perfection.

Alongside these primary machines, a host of auxiliary equipment supports the milling process. Conveyors facilitate the transportation of grains from storage to milling machines, while destoners remove impurities, such as stones and debris, ensuring only the best grains are processed. Furthermore, cyclones and bagging machines are indispensable in collecting the milled flour, separating it from air and other by-products. The synergy of these tools not only enhances efficiency but also bolsters the quality of the flour produced, establishing a foundation for the many culinary delights that can emerge from this age-old craft.

| Equipment | Function |

|---|---|

| Milling Machines | Convert maize to flour |

| Sifting Machines | Ensure flour consistency |

| Conveyors | Transport grains |

| Destoners | Remove impurities |

| Cyclones | Collect milled flour |

| Bagging Machines | Package flour for distribution |

Techniques of Milling: Crafting Quality Flour for Diverse Uses

At the heart of maize milling lies a refined set of techniques that transforms whole grains into fine flour, each method contributing distinct characteristics to the final product. Central to this process is the selection of machinery, including traditional stone mills and modern roller mills, each brewing its unique flavor and texture. A critical phase in milling is cleaning the grains, ensuring they are free from impurities before any grinding occurs. This stage is essential not just for the quality of the flour, but also for extending its shelf life. Following this, the grains are subjected to conditioning; a process where moisture levels are adjusted, allowing for more efficient milling and better flour extraction rates.

- Fine Grinding: Achieves a silky texture, ideal for baking and sauces.

- Coarse Grinding: Produces grits or polenta, perfect for hearty dishes.

- Sieving: Separates different flour grades, tailoring the fineness to specific culinary needs.

Once the milling techniques are executed, the resulting flour can serve an array of purposes, from baking bread to thickening soups. The nutritional profile of the flour is also a critical aspect, influenced by the milling technique employed. For instance, whole grain flour retains more nutrients compared to refined options. Below is a concise comparison of different maize flour types, illustrating their characteristics and culinary uses:

| Flour Type | Texture | Uses |

|---|---|---|

| Fine Flour | Smooth | Baking pastries and tortillas |

| Coarse Flour | Grainy | Making cornmeal and grits |

| Whole Grain Flour | Rough | Baking nutritious breads |

Sustainability in Milling: Practices for a Greener Future

In recent years, the milling industry has taken significant strides toward minimizing its ecological footprint and promoting environmentally responsible practices. By adopting innovative technologies and sustainable methods, millers are able to contribute toward a greener future while still delivering high-quality maize flour. Some of the pivotal practices include:

- Energy Efficiency: Implementing energy-efficient machinery can reduce power consumption. Techniques like regenerative braking and variable frequency drives optimize energy use.

- Water Conservation: Employing water-saving technologies and recycling systems helps mitigate water wastage during processing.

- Sustainable Sourcing: Collaborating with local farmers to source maize nurtures community relationships and lowers transportation emissions.

- Waste Utilization: Converting by-products into animal feed or bioenergy minimizes waste and promotes a circular economy.

Moreover, millers are focusing on transparency in their supply chains and environmentally friendly packaging materials to further enhance their sustainability efforts. This practice not only reduces plastic waste but also appeals to environmentally-conscious consumers. The incorporation of modern technology, such as blockchain for tracking ingredient origins, ensures ethical sourcing. To illustrate the impact of these practices, a comparative analysis of traditional versus sustainable milling methods can highlight clear benefits:

| Aspect | Traditional Milling | Sustainable Milling |

|---|---|---|

| Energy Consumption | High | Optimized |

| Water Usage | Excessive | Conserved |

| Waste Generation | Minimal | Utilized |

| Supply Chain Transparency | Limited | High |

Insights and Conclusions

As we conclude our exploration of maize milling, we emerge with a newfound appreciation for the intricate dance between grain and flour. This age-old process, steeped in tradition yet continuously evolving, is a testament to human ingenuity and our enduring relationship with food. From the moment a humble kernel is harvested to the final touch of flour ready for baking, every stage is a harmonious blend of science and artistry.

As we savor the flavors and textures that finely milled maize brings to our kitchens, let us also reflect on the skilled hands and innovative minds that make this transformation possible. The journey from field to flour is not just a tale of sustenance; it is a celebration of culture, craftsmanship, and community.

In recognizing the artistry involved in maize milling, we not only honor the past but also inspire a future of sustainable practices and culinary creativity. As we sift through our understanding of this ancient craft, may we continue to explore, appreciate, and elevate the humble maize, ensuring that each culinary creation is a tribute to the journey it undertook to get there.