From Grain to Flour: The Art and Science of Maize Milling

In the heart of many cultures lies a fundamental staple: maize. From the vibrant fields where golden kernels sway in the breeze to the bustling kitchens where they transform into beloved dishes, maize holds a significant place in our culinary heritage. Yet, the journey from a simple grain to a fine flour is a fascinating blend of art and science, a process steeped in tradition and enhanced by modern technology. This article embarks on a journey through the intricate world of maize milling, exploring the methodologies that turn raw grains into versatile flour, the nuanced techniques that preserve flavor and nutrition, and the innovations that are redefining this age-old practice. Join us as we delve into the rhythms of grinding wheels, the chemistry of texture, and the cultural significance of maize flour, illuminating the path from field to table.

Understanding the Maize Milling Process from Seed to Sifted Flour

The journey of maize from seed to sifted flour is a fascinating blend of nature’s wonders and human ingenuity. It all begins with the selection of high-quality maize seeds, which are carefully chosen for their genetic traits, such as drought resistance and yield potential. Once planted, these seeds thrive in nutrient-rich soil, absorbing sunlight and moisture to grow into robust maize plants. When the plants mature, they produce cobs that are harvested at the right time to ensure peak flavor and quality. After harvesting, the maize undergoes a meticulous process of drying and storing to remove excess moisture, which prevents spoilage and prepares it for milling.

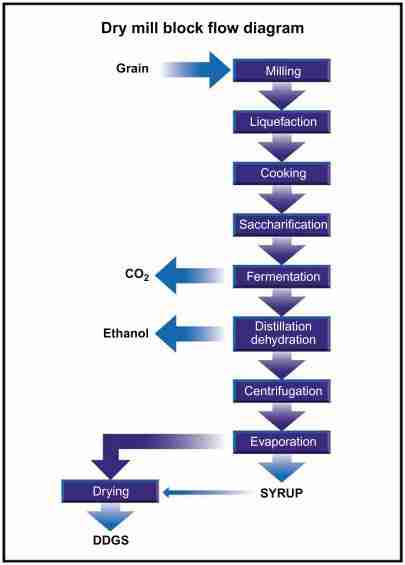

Next comes the milling process itself, where the dried maize enters a series of stages that transform it into fine flour. This involves cleaning, conditioning, and grinding. In the cleaning stage, impurities such as dirt, stones, and other foreign materials are removed. Then, the maize is conditioned by adding moisture to soften the outer hull, making it easier to grind. The grinding is done using specialized machinery that crushes the maize kernels, which are then sifted through fine screens to separate the flour into various grades. The end result is a fine, versatile flour, perfect for baking, cooking, and various culinary applications. Here’s a quick comparison of milling grades:

| Milling Grade | Description | Common Uses |

|---|---|---|

| Fine Flour | White maize flour, smooth texture | Baking, pastries |

| Coarse Flour | Rougher texture, retains more bran | Polenta, porridge |

| Cornmeal | Ground maize with a gritty texture | Bread, cornbread, tortillas |

Essential Factors in Grain Quality and Selection for Optimal Milling

When considering the journey of maize from its raw state to finely milled flour, several key attributes must be evaluated to ensure quality and performance during the milling process. The selection begins with the variety of maize, which greatly influences the final product. Distinct types such as dent, flint, or sweet corn contribute unique characteristics, such as kernel hardness and starch composition. Additionally, one should examine moisture content, as excessive moisture can lead to spoilage or hinder effective milling. Ideally, grains should maintain a moisture level between 14% to 15%, allowing for optimal milling efficiency and quality retention.

Another critical factor is kernel integrity, which affects the milling yield and flour characteristics. Grains should be uniform in size, free from cracks, and unaffected by pests or diseases. This quality can be assessed visually or through standardized testing methods. The geographical origin of maize can also play a crucial role; for example, maize grown in specific regions might exhibit distinct qualities due to soil composition and climate. To summarize, the critical factors in grain quality include:

- Variety of maize

- Moisture content

- Kernel integrity

- Geographical origin

Analyzing these aspects during the selection phase not only ensures better flour quality but also maximizes the efficiency of the milling process. A transparent evaluation of these factors establishes a foundation for producing flour that meets industry standards and consumer expectations. Understanding the interplay between these elements can lead to the development of new milling techniques and innovations.

The Impact of Milling Techniques on Flour Texture and Nutrition

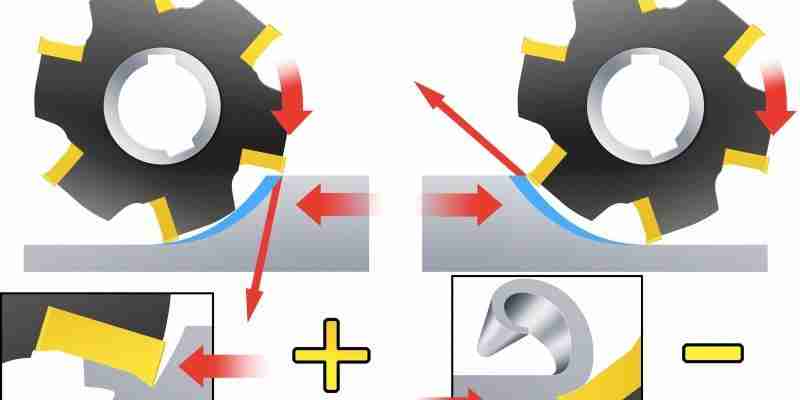

The journey from grain to flour hinges significantly on the milling techniques employed, each influencing both texture and nutritional value. Traditional stone milling, for instance, retains a larger portion of the bran and germ, producing flour that is coarser and richer in fiber and nutrients. In contrast, modern roller milling processes drive efficiency and yield a finer, more homogeneous flour by separating the endosperm from the bran and germ. However, this leads to a loss of essential nutrients that are often crucial in a balanced diet. The choice of milling technique thus acts as a decisive factor in determining the flour’s final characteristics.

When comparing the nutritional profiles and textures achieved through different milling methods, one can observe notable differences. The table below categorizes common techniques alongside their respective outcomes:

| Milling Technique | Texture | Nutritional Retention |

|---|---|---|

| Stone Milling | Coarse and Granular | High (Retains Bran and Germ) |

| Roller Milling | Fine and Powdery | Low (Loss of Nutrients) |

| Cold Milling | Medium and Fluffy | Moderate (Some Nutrients Preserved) |

Texture influences not just the sensory qualities of baked goods, but also their digestibility and the body’s ability to absorb nutrients. Coarser flours, often favored in artisanal baking, can slow the absorption of sugars, providing a steadier energy release. On the other hand, finer flours are more versatile for a range of culinary uses, but may lead to quicker spikes in blood glucose levels. Each milling technique offers a trade-off, making the miller’s choice crucial in navigating both the art and science of flour production.

Innovative Practices for Sustainable and Efficient Maize Milling Operations

In the realm of maize milling, innovative practices are shaping the future of operations, fostering sustainability while maximizing production efficiency. One prominent approach involves the integration of renewable energy sources into milling processes. Solar panels and wind turbines can power the milling equipment, significantly reducing dependence on conventional energy and decreasing the carbon footprint. Furthermore, modern milling factories are increasingly adopting energy-efficient machinery designed to optimize energy use, thereby lowering operational costs and promoting a greener environment.

Another key practice is the implementation of waste reduction techniques throughout the milling process. Advanced technologies enable millers to minimize by-products, ensuring that every kernel of maize is utilized effectively. For instance, by-products such as husks and germ can be repurposed into animal feed or biofuel. Here’s a simple table showcasing potential by-products and their applications:

| By-Product | Application |

|---|---|

| Maize Germ | Oil Production |

| Husks | Animal Feed |

| Starch Residue | Bioplastics |

Through these innovative practices, maize milling operations are not just cultivating high-quality flour but are truly steering towards a sustainable future.

Closing Remarks

As we conclude our exploration of “From Grain to Flour: The Art and Science of Maize Milling,” we find ourselves standing at the intersection of tradition and innovation. The journey of maize, from its cultivation in sun-kissed fields to its transformation into fine flour, encapsulates a rich tapestry of cultural heritage and technological advancement. Each grinding of the mill echoes the labor of generations, while the precision of modern milling techniques reflects our ever-evolving understanding of this staple grain.

In every teaspoon of maize flour, there lies a story—a narrative woven through time, innovation, and the relentless pursuit of perfection. Whether you’re a home baker crafting cornbread or a chef experimenting in a bustling kitchen, the flour derived from maize holds the power to connect us to both our past and our future.

As we continue to cultivate our appreciation for this essential ingredient, let us embrace the science behind the art of milling, recognizing the nuanced flavors and textures it can bring to our culinary endeavors. In a world where food is both sustenance and an expression of identity, maize flour stands as a testament to the ingenuity of humankind—ready to inspire our next creation.