In the quiet hum of the mill, where ancient grains meet modern machinery, a remarkable transformation unfolds—one that quietly fuels our mornings and shapes our culinary experiences. “From Grain to Flake: The Art and Science of Cereal Milling” invites readers into the intricate world of milling, an age-old craft steeped in tradition yet driven by innovation. As we explore the delicate balance between artistry and engineering, we’ll uncover the meticulous processes that take humble grains and elevate them into the crisp, crunchy flakes we pour into our bowls. Join us on this journey through the silos and spouts, where the rhythmic dance of grain milling reveals not only a vital food industry but also the intricate relationship between nature’s bounty and human ingenuity.

The Journey of Grain: Understanding the Milling Process

Transforming whole grains into delightful flakes is an intricate process that marvels both the art and science of milling. It commences with the careful selection of premium grains, where quality and moisture content are paramount. The grains undergo thorough cleaning to remove any impurities, setting the stage for a meticulous milling operation. Key steps in the process include:

- Conditioning: Grains are moistened to toughen the bran and soften the endosperm.

- Grinding: Grains are crushed between metal rollers, breaking them down into smaller particles.

- Sifting: A series of screens separate the fine flour from coarser pieces, ensuring uniformity.

The efficiency of grain milling relies heavily on precision machinery that can handle varied grain types while maintaining consistent output. Each milling unit is designed to target specific grain properties, allowing for custom blends catered to diverse preferences. Throughout this journey, the flavor and nutritional profile of the grains evolve, ultimately creating a product ready for our breakfast tables. Below is a representation of the milling stages:

| Stage | Description |

|---|---|

| Cleaning | Removing stubborn impurities and foreign materials. |

| Conditioning | Preparing grains for effective grinding. |

| Grinding | Breaking down grains into flour or flakes. |

| Sifting | Separating fine flour from larger particles. |

Nutritional Balance: How Milling Affects Cereal Quality

The journey from grain to flake is as much an art as it is a science, particularly when it comes to achieving nutritional balance. Milling determines not only the flavor and texture of the final product but also significantly impacts its nutritional profile. The degree of milling—whether whole grain, refined, or somewhere in-between—carries implications for essential nutrients. With every pass through the mill, vital components such as fiber, vitamins, and minerals can be lost or preserved, influencing the health benefits of cereal products. For instance, while whole grains retain their bran and germ layers, enriched flours may provide a smattering of synthetic nutrients designed to compensate for what has been stripped away.

Furthermore, the milling process itself can vary widely, employing different techniques and equipment that affect end quality. The selection of grinding methods, sifting, and separation greatly alters the nutrient availability in cereals. Factors such as grain hardness, moisture content, and processing temperature play a crucial role in preserving or degrading nutrients. Here’s a brief overview of how different milling types affect the nutritional content:

| Milling Type | Nutritional Impact |

|---|---|

| Whole Grain Milling | Retains bran, germ, and endosperm; highest fiber and nutrient content |

| Refined Milling | Removes bran and germ; lower fiber and micronutrient levels |

| Enriched Milling | Some nutrients added back post-processing; still lacks natural nutrients found in whole grains |

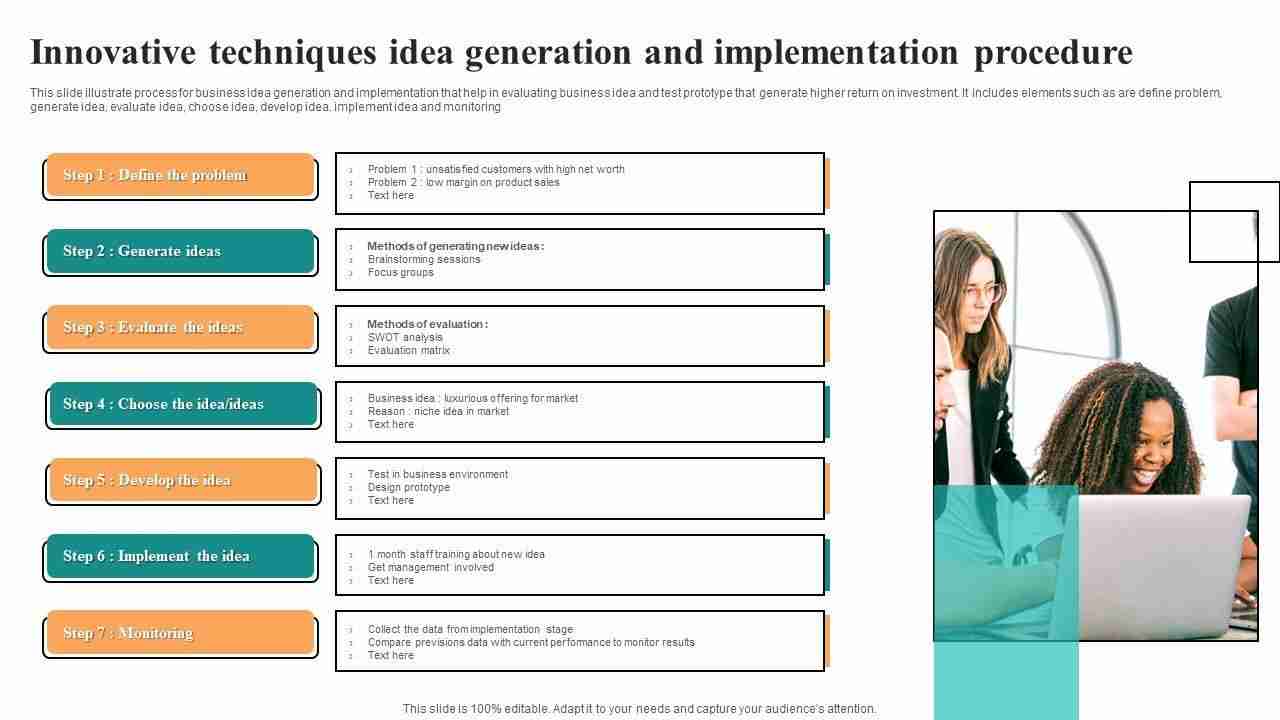

Innovative Techniques: Advancements in Cereal Milling Technology

In recent years, the cereal milling industry has undergone remarkable advancements, driven by a blend of innovation and technology. New milling techniques have emerged that enhance not only the quality of the final product but also improve efficiency and sustainability in the production process. High-pressure roller milling is one such technique, enabling the production of finer particles while maintaining the integrity of the grain’s nutritional profile. Furthermore, the integration of digital technologies, such as IoT sensors and machine learning algorithms, allows for real-time monitoring and adjustments, ensuring that the milling process consistently meets desired outcomes.

Additionally, the exploration of alternative grains has led to exciting developments in milling techniques. By investing in specialized equipment capable of handling various types of grains, producers can diversify product offerings and cater to a growing market of health-conscious consumers. For instance, the introduction of stone milling reflects a return to traditional methods while benefitting from modern advancements, providing a unique flavor profile and texture. The following table summarizes some cutting-edge milling techniques and their respective outcomes:

| Technique | Benefits |

|---|---|

| High-Pressure Roller Milling | Produces finer flour, minimizes heat generation |

| Digital Monitoring Systems | Enhances precision and efficiency in milling |

| Stone Milling | Retains grain nutrients, unique texture |

| Alternative Grain Milling | Diverse product range, meets health trends |

Sustainability Matters: Eco-Friendly Practices in Grain Processing

In the journey from grain to flake, eco-friendly practices play an essential role in minimizing the environmental impact of cereal milling. By emphasizing sustainable sourcing and innovative processing techniques, the industry can significantly reduce waste and conserve resources. Cereals are often grown in diverse conditions, and the adoption of regenerative agricultural methods can enhance soil health while promoting biodiversity. Moreover, using organic inputs and minimizing chemical fertilizers ensures that the grains processed are of the highest standard, both for human consumption and for the planet.

Energy efficiency is another cornerstone of sustainable practices within the grain processing sector. Milling facilities are increasingly investing in renewable energy sources, such as solar or wind power, to minimize their dependence on fossil fuels. Additionally, the implementation of advanced technology allows for enhanced monitoring of energy consumption, leading to better overall efficiency. By optimizing production lines and reducing unnecessary energy expenditure, milling operations can operate effectively while contributing to a healthier planet. Below is a comparison of traditional versus sustainable milling methods that highlights the benefits of eco-friendly practices:

| Aspect | Traditional Milling | Sustainable Milling |

|---|---|---|

| Energy Source | Fossil Fuels | Renewable Energy |

| Waste Generation | High | Minimal |

| Water Use | High | Conservation Techniques Implemented |

| Input Materials | Synthetic Fertilizers | Organic Inputs |

In Retrospect

As we conclude our exploration of the intricate journey from grain to flake, it becomes clear that cereal milling is a fascinating blend of tradition and innovation. This often-overlooked process not only transforms humble grains into nutritious breakfast staples but also embodies the remarkable interplay of art and science. Each flake represents countless hours of expertise, careful precision, and a commitment to quality that spans generations.

Ultimately, understanding the art and science behind cereal milling deepens our appreciation for the food we consume every day. It is a reminder that even the simplest pleasures, like enjoying a bowl of cereal, are the result of complex processes, skilled craftsmanship, and dedicated ingenuity. As we pour our next serving, let us cherish the journey that brought it from the field to our table, continuing to celebrate the rich narrative woven into every crunchy bite.