From the ancient Mayans to modern-day farmers, maize has been a staple crop that has sustained civilizations for centuries. However, the journey from field to flour is no simple task. Maize milling is an intricate art that requires skill, precision, and dedication. In this article, we will explore the mesmerizing process of turning maize kernels into fine, versatile flour that is used in a myriad of culinary creations. Join us as we delve into the fascinating world of maize milling and uncover the secrets behind this essential agricultural practice.

The Importance of Proper Maize Milling Techniques

When it comes to maize milling, proper techniques are key to producing high-quality flour that can be used in a variety of products. The process of turning maize kernels into flour involves several steps that must be executed with precision to ensure a consistent and uniform final product. From cleaning and de-germinating the maize to grinding and sifting the flour, each step plays a crucial role in producing flour that meets industry standards.

Utilizing advanced milling equipment and following best practices, such as adjusting the moisture content of the maize and monitoring the particle size during grinding, are essential for achieving optimal results. Additionally, maintaining a clean and organized mill environment, as well as regularly servicing and calibrating equipment, can help prevent contamination and ensure the safety and quality of the final product. By mastering the art of maize milling, producers can create flour that is not only nutritious but also ideal for use in a wide range of food products.

Selecting the Right Equipment for Maize Milling

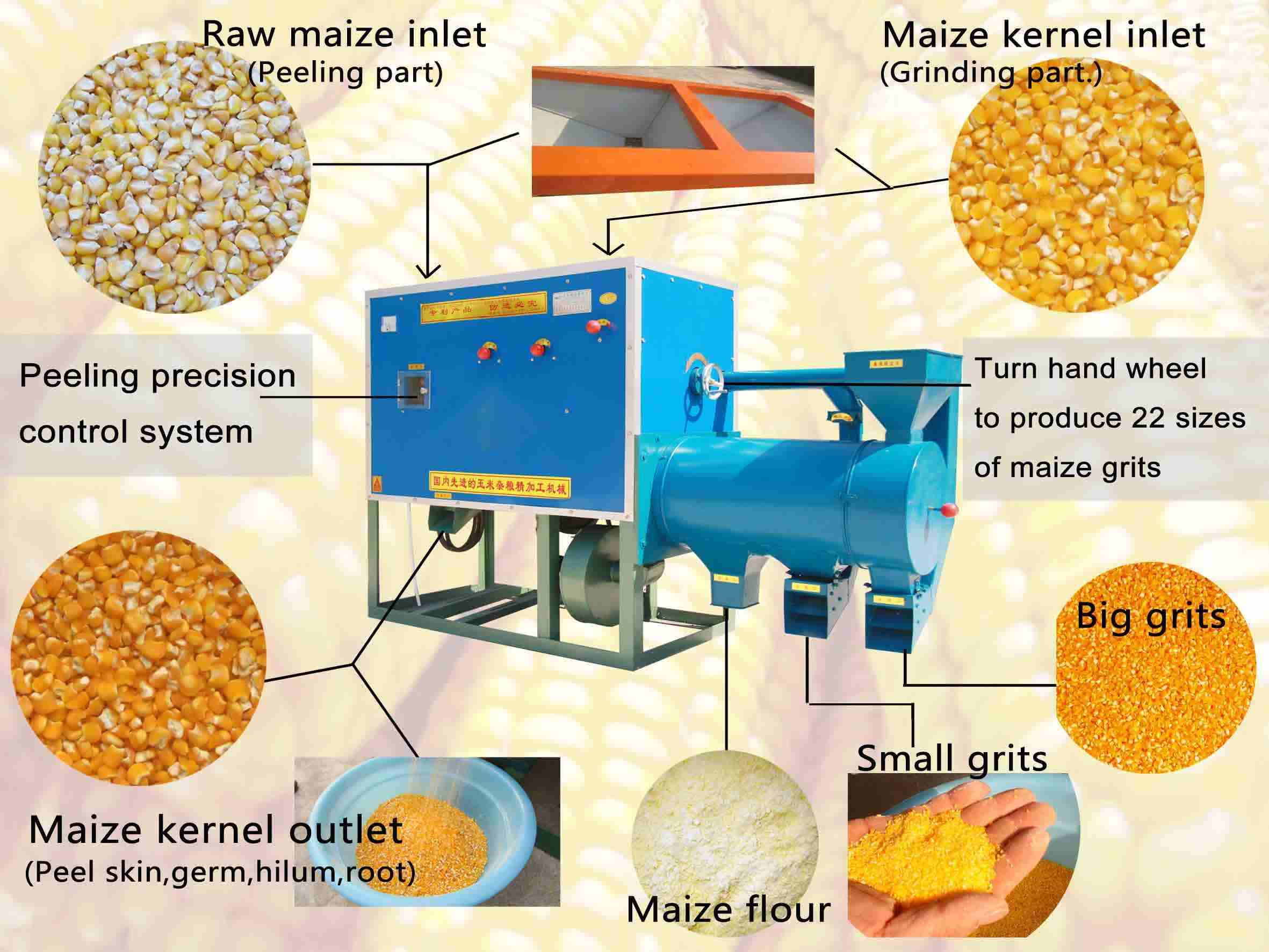

When it comes to maize milling, selecting the right equipment is crucial for achieving a high-quality end product. From cleaning and degerminating the maize kernels to grinding and sifting the flour, each step requires the right machinery to ensure efficiency and consistency.

One essential piece of equipment for maize milling is the degerminator, which helps to remove the germ from the maize kernel. This process is vital for producing refined maize flour that is free from impurities. Additionally, a hammer mill is commonly used for grinding the maize kernels into flour, while a plansifter is used for sifting the flour to achieve the desired fineness.

| Equipment | Function |

|---|---|

| Degerminator | Removes germ from maize kernel |

| Hammer Mill | Grinds maize kernels into flour |

| Plansifter | Sifts flour to desired fineness |

Key Steps in the Maize Milling Process

Milling maize is a complex process that involves several key steps to turn the corn from the field into fine flour ready for consumption. The first step in the process is cleaning the maize to remove any impurities such as dirt, stones, and other debris. This ensures that the final product is of the highest quality.

Once the maize has been cleaned, it is then dried to the correct moisture levels to prevent mold and ensure optimal milling. The next step is to grind the maize into a coarse meal using a milling machine. This meal is then sifted to separate the bran from the flour, resulting in a fine, powdery substance that is ready to be used in a variety of dishes.

Tips for Maintaining Quality and Efficiency in Maize Milling Operations

Maintaining quality and efficiency in maize milling operations is crucial for producing high-quality flour that meets customer expectations. One tip for achieving this is to regularly inspect and clean the milling equipment to ensure optimal performance. **Proper maintenance** can prevent breakdowns and reduce downtime, ultimately increasing productivity and efficiency. Additionally, regularly calibrating the milling equipment and monitoring the milling process can help ensure consistent quality in the final product.

Another tip for maintaining quality and efficiency in maize milling operations is to source high-quality maize grains from reputable suppliers. Using premium quality maize grains can result in better flour quality and higher yields. Furthermore, investing in modern milling technology and equipment can improve efficiency and reduce operating costs. By staying up-to-date with the latest advancements in maize milling technology, mill operators can optimize their operations for maximum quality and efficiency.

| Tip | Description |

|---|---|

| Regular Equipment Inspection | Inspect and clean milling equipment for optimal performance |

| Source High-Quality Maize | Buy premium maize grains for better flour quality |

The Way Forward

As we conclude our exploration into the art of maize milling, it is clear that this age-old process holds an undeniable significance in our history and culture. From the fertile fields where the maize is grown to the skilled hands of the millers who transform it into flour, every step of the journey is steeped in tradition and craftsmanship. So the next time you enjoy a piece of freshly baked bread or a steaming bowl of tortillas, take a moment to appreciate the intricate journey that brought that flour to your plate. The art of maize milling may be ancient, but its impact on our lives today is as profound as ever.