In the heart of many homes and kitchens across the globe lies a humble yet versatile ingredient: maize. Known by many names—corn in North America, sweetcorn in the UK, and maize in others—this golden grain is far more than just a staple for farmers; it is a cornerstone of culinary traditions and innovations alike. From the ancient civilizations that revered it as sacred to the modern-day artisans who have perfected the craft, maize has journeyed through time, transforming from cob to flour in a process that marries both art and science. In this exploration of maize milling, we delve into the intricacies of how this grain undergoes its metamorphosis, revealing the techniques, technologies, and traditions that come together to produce the fine flour that flourishes in kitchens. Join us as we uncover the delicate balance between age-old practices and cutting-edge methods that shape the future of maize milling, celebrating the versatility of a grain that unites cultures and palates around the world.

Understanding the Anatomy of Maize: A Journey from Cob to Kernels

To truly appreciate the transformation of maize, one must first delve into its intricate structure. The cob, a cylindrical spine that holds the kernels together, is often overlooked yet is crucial in understanding how maize grows and develops. Wrapped in husks, each cob can yield hundreds of kernels, which are the star players in this journey. The kernels themselves are packed with nutrients and energy, encased in a protective outer layer called the pericarp. This armor not only safeguards the seed but also influences its texture and cooking properties, affecting everything from the taste of the final product to its suitability for milling.

The milling process begins with these harvested cobs, which must be separated from the kernels. Each kernel undergoes a meticulous transformation, where its anatomy plays an essential role. The kernel consists of three primary components: the endosperm, which provides energy; the germ, the embryo of the plant responsible for sprouting; and the bran, the protective outer layer rich in fiber. Understanding the proportions and functions of these parts is vital for millers seeking to produce flour with specific characteristics. This knowledge dictates every step of the milling process, as illustrated in the table below:

| Kernel Component | Function | Impact on Flour |

|---|---|---|

| endosperm | Provides carbohydrates and energy | Determines flour texture and protein content |

| germ | Source of vitamins and oils | Influences flavor and nutritional value |

| bran | Offers fiber and protects the kernel | Adds color and texture to flour |

As the milling journey unfolds, knowing these details equips millers with the insights needed to craft high-quality flour tailored to specific culinary applications. From tortillas to pastries, the variations in kernel composition directly inform the milling techniques employed. In this ongoing exploration of maize’s anatomy, it becomes clear that each component contributes uniquely to the final product, making the seemingly simple act of milling a beautiful blend of art and science.

Mill Design and Technology: Innovations in Maize Milling Processes

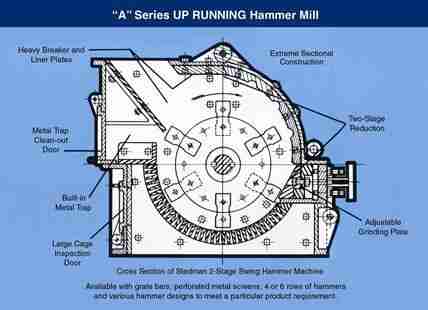

In the ever-evolving field of maize milling, technology plays a pivotal role in enhancing efficiency and production quality. Traditional methods have given way to innovative machinery designed to streamline the entire process from cob to flour. Advanced grinding technologies are now employed to ensure uniform particle size, which not only improves the texture of the flour but also preserves the essential nutrients contained within the maize. The adoption of automated systems enables real-time monitoring and adjustments, resulting in higher throughput while minimizing waste. Additionally, integrating data analytics allows millers to predict equipment maintenance needs, ensuring uninterrupted production cycles.

Moreover, sustainability has become a core component of modern milling operations, with eco-friendly practices being integrated into the production processes. Mills are increasingly utilizing biomass energy from byproducts, reducing dependence on fossil fuels and cutting operational costs. The introduction of innovative wet milling techniques enhances the extraction of valuable components, such as starch and protein, which can be repurposed in various industries, thereby enhancing the circular economy. Below is a summary of specific innovations in the maize milling process:

| Innovation | Description |

|---|---|

| Automated Milling Lines | Reduces labor costs and increases speed and precision. |

| Advanced Sorting Technology | Improves grain quality by removing impurities and damaged kernels. |

| Energy-Efficient Machinery | Minimizes energy consumption while maximizing output. |

| Byproduct Utilization | Reduces waste by converting husks and germ into useful products. |

The Nutritional Transformation: How Milling Affects Maizes Health Benefits

The journey of maize from cob to flour involves more than just transforming form; it significantly impacts its nutritional profile. When maize undergoes milling, the degree of processing determines the retention or loss of vital nutrients. Whole maize retains essential components such as fiber, vitamins, and minerals, while refined maize may strip away valuable attributes. A careful selection of milling processes, like stone grinding versus steel milling, can preserve beneficial phytochemicals and antioxidants, enhancing the overall health benefits of the final product.

Moreover, the texture and particle size produced during milling can influence the bioavailability of nutrients. Finer flours may lead to quicker digestion, which affects satiety and blood sugar levels. Additionally, the milling method can impact the following nutrients:

| Nutrient | Whole Maize | Refined Maize |

|---|---|---|

| Fiber | High | Low |

| Vitamin E | Present | Reduced |

| Magnesium | High | Lower |

Investing in minimally processed flours not only supports health but also celebrates the culinary richness of maize. By understanding the effects of milling on its nutritional quality, consumers can make more informed choices that elevate their meals while harnessing the full potential of maize’s health benefits.

Best Practices for Flour Production: Balancing Quality and Efficiency

Achieving the perfect balance between quality and efficiency in flour production requires a strategic approach to milling techniques and ingredient selection. A thorough understanding of the maize kernel and its properties is crucial. Selecting high-quality maize not only enhances flavor and nutrition but also optimizes the milling process. Key factors to consider include moisture content, kernel hardness, and the presence of impurities. Implementing state-of-the-art milling equipment that embraces precision technology leads to finer granulation while minimizing waste. Traditional stone mills combined with modern roller mills can create a diverse range of flour types, ensuring that both artisanal and large-scale production needs are met.

To further enhance operational efficiency, establishing standard operating procedures (SOPs) can streamline workflows and reduce errors. Regular maintenance of milling machinery ensures optimal performance and longevity, preventing unexpected downtimes that can disrupt production schedules. Additionally, investing in quality control measures at various stages—from grain reception to finished flour storage—guarantees that customers receive consistent, premium products. An effective approach may include the implementation of batch testing for moisture and protein levels, allowing producers to adjust formulations as necessary. By fostering a culture of continuous improvement, flour producers can adeptly navigate the delicate balance between maintaining high standards and maximizing output.

The Conclusion

As we journey from cob to flour, the story of maize milling transcends mere agricultural practice; it embodies the harmonious interplay between tradition and innovation, art and science. Each stage of the milling process is a testament to human ingenuity, transforming a simple kernel into a versatile ingredient that serves as the backbone of countless cuisines and cultures around the world. The millers, with their age-old techniques and modern technologies, bridge the gap between nature’s bounty and the culinary creations that enrich our tables.

While the process may seem straightforward, beneath the surface lies a complex tapestry woven from historical significance, nutritional value, and economic impact. As we savor the fruits of this labor—be it in the form of cornbread, tortillas, or polenta—we are reminded of the deep-rooted connections we share with this staple grain.

In an era where sustainability and food security dominate discourse, understanding the art and science of maize milling becomes ever more vital. It invites us to appreciate the journey of our food, recognize the skilled hands that produce it, and consider the broader implications of our consumption choices. As we close this exploration of maize milling, let us carry forth the knowledge gleaned and celebrate the humble maize in all its forms—a testament to the past and a beacon for the future.