Have you ever wondered about the intricate process behind creating your favorite cereal? From harvesting to packaging, cereal processing is a fascinating art that involves a careful balance of science and creativity. In this article, we will delve into the world of cereal processing and explore the various steps involved in crunching the numbers to create the perfect breakfast staple. Join us on a journey through the science and artistry of cereal processing.

Mastering the Moisture Content: Key to Quality

When it comes to cereal processing, the key to achieving high quality products lies in mastering the moisture content. Controlling the moisture levels in cereal products is crucial for maintaining freshness, texture, and shelf life. By carefully monitoring and adjusting the moisture content throughout the processing stages, manufacturers can ensure consistent quality and taste in their products.

One effective method for managing moisture content is through the use of specialized equipment such as moisture meters and dryers. These tools allow manufacturers to accurately measure and control the moisture levels in the raw materials and final products. Additionally, implementing proper storage and packaging techniques can help prevent moisture absorption and maintain product integrity. By paying close attention to moisture content, cereal processors can achieve optimal product quality and customer satisfaction.

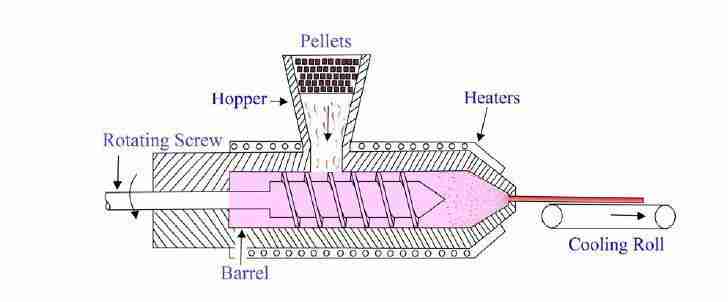

Optimizing Extrusion Parameters for Perfect Crunch

When it comes to achieving the perfect crunch in cereal processing, optimizing extrusion parameters is key. By carefully adjusting factors such as temperature, screw speed, and moisture content, manufacturers can fine-tune their process to produce crispy, crunchy cereals that consumers love. One important parameter to consider is the die design, which can impact the texture and shape of the final product. Experimenting with different die configurations can help achieve the desired level of crunchiness.

Another crucial factor in optimizing extrusion parameters is the choice of ingredients. Using quality grains and additives can enhance the crunchiness of the cereal. Additionally, adjusting the formulation to include ingredients like malt extracts or enzymes can help improve the overall texture of the product. By carefully balancing these parameters, manufacturers can consistently produce cereals with the perfect crunch that keep customers coming back for more.

Innovative Ways to Enhance Nutrient Preservation in Cereal Processing

One innovative way to enhance nutrient preservation in cereal processing is by utilizing vacuum packaging techniques. By removing oxygen from the packaging, the risk of oxidation and nutrient degradation is significantly reduced. This method helps to maintain the freshness of the cereal and preserves important vitamins and minerals.

Another creative approach is to incorporate natural preservatives, such as citrus extracts or rosemary oil, into the cereal processing. These natural additives not only help to extend the shelf life of the product but also contribute to the overall nutritional value. By thinking outside the box and experimenting with different preservation methods, cereal manufacturers can find unique ways to enhance the nutrient content of their products while keeping them fresh and flavorful.

In Conclusion

In conclusion, the art of cereal processing is a fascinating and intricate process that involves a delicate balance of science and creativity. From selecting the perfect ingredients to fine-tuning the manufacturing process, every step plays a crucial role in producing the perfect bowl of cereal. So next time you pour yourself a bowl, take a moment to appreciate the numbers that go into creating that delicious crunch. Remember, behind every spoonful of cereal lies a world of calculations and precision that ensure your breakfast is nothing short of perfection.