Have you ever stopped to think about the intricate process that goes into turning a simple grain into the cereal that fills our bowls each morning? From milling to shaping to toasting, cereal processing is a fascinating blend of art and science. In this article, we will break down the complex science behind cereal processing and explore the steps that transform raw ingredients into the crispy, tasty breakfast staple we all know and love. So grab a spoon and get ready to delve into the world of cereal production!

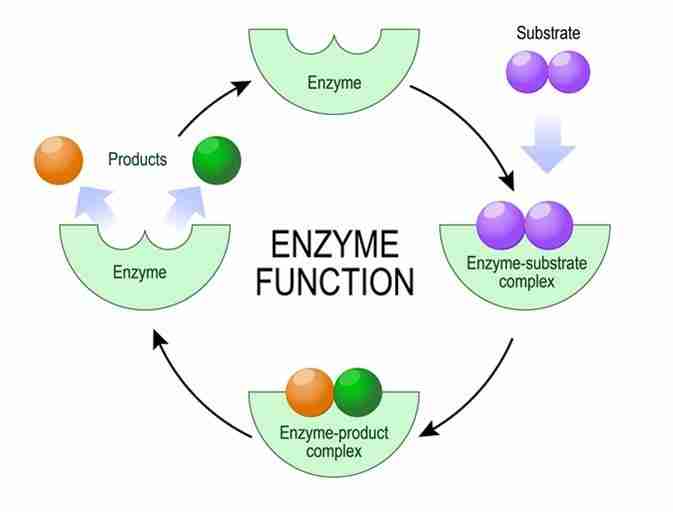

Exploring the Role of Enzymes in Cereal Processing

Enzymes play a crucial role in the complex process of cereal processing, aiding in the breakdown of starches and proteins to create the desired texture, flavor, and nutritional profile of the final product. From the milling of grains to the baking of bread, enzymes are the unsung heroes that facilitate the transformation of raw ingredients into our favorite breakfast cereals and snacks. By understanding the specific functions of different enzymes, food scientists can optimize processing conditions to achieve the desired characteristics in the end product.

One key enzyme involved in cereal processing is amylase, which breaks down starch molecules into sugars, providing the necessary fuel for fermentation during baking. Proteases, on the other hand, help to degrade proteins, improving dough elasticity and creating a softer texture in the final product. Lipases, meanwhile, contribute to the development of flavor by breaking down fats into their component parts. By harnessing the power of enzymes, food manufacturers can innovate and create new products that cater to evolving consumer preferences and dietary trends.

Maximizing Nutrient Retention in Cereal Products

When it comes to maximizing the retention of nutrients in cereal products, understanding the science behind cereal processing is essential. By breaking down the complex processes involved in the production of cereals, we can better appreciate the importance of preserving the nutritional value of these staple foods.

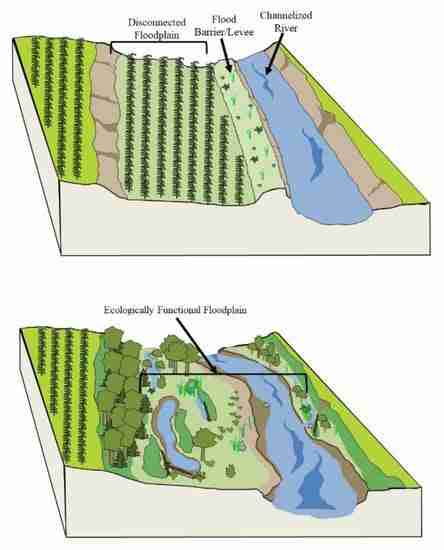

One key factor in nutrient retention is the method of milling grains. **Stone milling** is known to be gentler on the grains, preserving more of their natural nutrients compared to **steel roller milling**. Additionally, techniques such as **germination** and **fermentation** can enhance the bioavailability of nutrients in cereals, making them more easily absorbed by the body. By incorporating these practices into the production of cereal products, we can ensure that consumers are getting the most nutritional benefit from their daily servings of grains.

Understanding the Impact of Processing Methods on Digestibility

When it comes to , it’s essential to break down the science behind cereal processing. Different processing techniques can significantly affect the digestibility of cereals, influencing how our bodies absorb nutrients. Let’s take a closer look at some key factors that determine digestibility:

- Grain Size: The size of the grain can impact digestibility, with smaller grains generally being easier to digest.

- Heat Treatment: Heat processing methods such as cooking or baking can break down complex carbohydrates into simpler forms, making them more digestible.

- Enzyme Activity: Enzymes present in some processing methods can help pre-digest the cereals, increasing their overall digestibility.

| Processing Method | Digestibility Rating |

|---|---|

| Boiling | High |

| Milling | Medium |

| Extrusion | Low |

Tips for Improving Cereal Processing Efficiency

One key aspect of optimizing cereal processing efficiency is proper equipment maintenance. Regularly cleaning and inspecting equipment such as conveyors, sifters, and dryers can help prevent breakdowns and ensure smooth operation. Additionally, calibrating equipment settings regularly can help maximize output and minimize waste.

Another important factor to consider is the quality of raw materials used in the cereal processing. Ensuring that grains are properly cleaned and dried before processing can help improve the overall efficiency of the process. Investing in high-quality ingredients can also result in a better end product, which can increase customer satisfaction and brand loyalty. By focusing on equipment maintenance and ingredient quality, cereal processors can take proactive steps towards improving efficiency and profitability.

To Wrap It Up

So there you have it, a closer look at the fascinating science behind cereal processing. From the raw grains to the finished product, each step in the process involves a delicate balance of art and science. Next time you dig into your favorite bowl of cereal, take a moment to appreciate the intricacies that go into transforming those simple grains into a breakfast staple. And remember, the next time you pour yourself a bowl of cereal, you’re not just eating breakfast – you’re enjoying the fruits of centuries of agricultural innovation and food technology.