In the heart of bustling cities and quiet countryside alike, the journey of cereal—from golden grains swaying in the wind to the finely milled flour that enriches our daily bread—unfolds as a remarkable interplay of art and science. “From Grain to Gold: The Art and Science of Cereal Milling” invites readers to explore this intricate transformation, where tradition meets technology in a timeless dance of innovation and craftsmanship. As we delve into the milling process, we will uncover the meticulous techniques and sophisticated machinery that convert raw grains into the foundation of countless culinary creations. Join us on this enlightening journey that not only celebrates the rich heritage of cereal milling but also underscores its vital role in feeding the world today.

The Transformation Process Unveiled: Understanding Cereal Milling Techniques

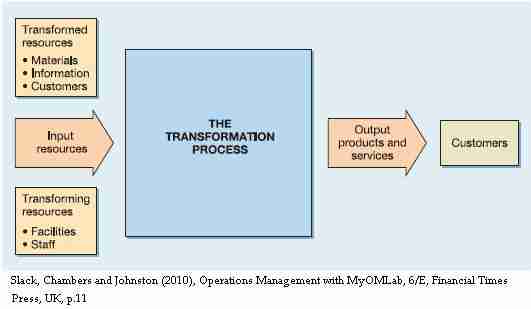

The journey from raw grain to fine flour involves a meticulous transformation process that combines both artistry and technology. At the heart of cereal milling lies the concept of grinding, where various techniques are employed to achieve the desired texture and quality. Key methods include:

- Roller milling: This technique utilizes pairs of rotating cylindrical rollers to crush grain, offering precision and uniformity.

- Stone milling: An ancient technique that uses stone grinders to produce flour, imparting a unique flavor and nutritional profile.

- Hammer milling: In this process, high-speed hammers break down the grain, ideal for producing coarse powders.

Each milling method serves different purposes, depending on the final product and desired characteristics like texture and flavor. Understanding the factors that influence these processes can provide insight into how milling affects the nutritional value of grains. For instance, variations in the extraction rate—the amount of bran and germ retained in the flour—can significantly impact the overall quality and health benefits of the end product. The table below summarizes some key aspects of popular milling techniques:

| Milling Technique | Texture | Flavor Profile | Nutritional Value |

|---|---|---|---|

| Roller Milling | Smooth | Neutral | Varies |

| Stone Milling | Coarse | Nutty | High |

| Hammer Milling | Coarse to Fine | Strong | Varies |

Nurturing Quality: Selecting the Right Grains for Optimal Milling

Selecting the finest grains is the cornerstone of superior milling. Grains undergo a transformation from humble seeds to the rich, versatile flours that are integral to culinary creations. The journey begins with understanding the key characteristics that differentiate one grain from another. Factors such as moisture content, protein levels, and kernel hardness play a substantial role in determining the milling outcome. For instance, high-protein grains yield stronger gluten structures, essential for breads, while softer grains are preferable for delicate pastries.

Moreover, the importance of grain purity cannot be overstated. Contaminants and foreign seeds can drastically alter the quality and consistency of the final product. Therefore, sourcing grains from trusted suppliers ensures not only quality but also supports sustainable practices. Connoisseurs often emphasize the significance of regional varieties, which can offer unique flavors and performance characteristics. A brief overview of popular grain types indicates how each contributes to the artistry of milling:

| Grain Type | Use | Key Characteristics |

|---|---|---|

| Hard Wheat | Breads | High protein, strong gluten |

| Soft Wheat | Cakes, Pastries | Lower protein, fine texture |

| Rye | Breads | Distinct flavor, dense crumb |

| Corn | Polenta, Tortillas | Sweet flavor, versatile use |

Precision in Production: Innovative Technologies Shaping the Milling Industry

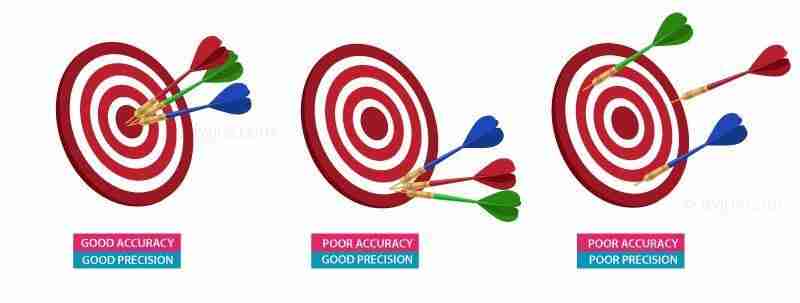

The milling industry has entered a new era characterized by cutting-edge advancements that enhance precision and efficiency. At the forefront of these innovations is automation, which streamlines every stage of the milling process. Intelligent systems now monitor grain quality in real time, ensuring that only the finest grains make their way into production. Sustainable technologies have also emerged, enabling mills to reduce waste and energy consumption, thereby contributing to a greener footprint. Moreover, sophisticated software solutions provide precise data analytics, allowing millers to make informed decisions and optimize their operations.

One of the most transformative technologies is the use of computerized control systems that enable precise adjustments during milling. These systems not only enhance consistency but also allow for greater flexibility in adapting to various grain types. Milling companies are increasingly integrating AI-driven solutions that predict maintenance needs, preventing costly downtime. As the industry’s needs evolve, the integration of IoT devices ensures that every machine, from cleaners to grinders, operates in harmony, leading to increased output and quality. To visualize this technological leap, consider the following table that outlines key innovations and their impacts:

| Innovation | Impact |

|---|---|

| Automation | Streamlines processes, enhances efficiency |

| Sustainable Technologies | Reduces waste and energy use |

| Computerized Control Systems | Ensures precision and consistency |

| AI-Driven Solutions | Predicts maintenance, minimizes downtime |

| IoT Integration | Connects machinery for optimized output |

Sustainability and Beyond: Best Practices for Eco-Friendly Milling Operations

To transform cereal grains into high-quality flour while minimizing environmental impact, milling operations must adopt a series of best practices centered around sustainability. Implementing energy-efficient technologies is paramount. Techniques such as utilizing renewable energy sources, optimizing process equipment for reduced power consumption, and investing in smart machinery that adjusts to real-time demands can significantly lower the carbon footprint. Furthermore, the practice of waste recycling is essential; byproducts of milling, like bran and germ, can be repurposed for animal feed or health supplements, thereby extending the lifecycle of raw materials and contributing to a circular economy.

Water conservation is another critical aspect of maintaining eco-friendly milling operations. Modern mills are employing closed-loop water systems which recycle water used during processing, drastically lowering overall consumption. Additionally, scheduling maintenance and audits ensures that equipment operates efficiently and prevents leaks or spills, ultimately safeguarding local water sources. Incorporating sustainability into daily operations enhances not just the environmental profile, but also boosts overall efficiency and profitability. The milling industry can truly flourish by embracing these innovative approaches, ensuring that each system contributes to a healthier planet.

Final Thoughts

As we conclude our journey through the intricate world of cereal milling, we find ourselves standing at the crossroads of tradition and innovation. From the humble grain that sprouted in the fields to the finely milled flour that graces our tables, each step in this process is a testament to human ingenuity and the ageless bond we share with the land. The artistry of milling, honed over centuries, marries seamlessly with cutting-edge technology, propelling this age-old craft into the future.

In the dance between science and art, we witness the transformation of simple kernels into essential staples, fueling not just our bodies but also our cultures and economies. As we celebrate the mastery of millers—those skilled artisans who have perfected their craft—we are reminded of the myriad hands and hearts involved in bringing food from farm to fork.

So, the next time you sprinkle flour into your favorite recipe or enjoy a warm slice of bread, take a moment to reflect on the journey that grain has undertaken. In every grain lies a story, a legacy of care, creativity, and complex processes that ultimately turn the ordinary into the extraordinary. In this way, we are all participants in the age-old tradition of turning grain into gold, nourishing both body and spirit. Thank you for joining us in exploring this fascinating odyssey from field to flour, as we continue to savor the fruits of the milling artistry crafted through the ages.