Grinding the Grain: The Art and Science of Cereal Milling

In the heart of every loaf of bread, bowl of cereal, and handful of granola lies an intricate process that transforms humble grains into the versatile flours that form the foundation of many culinary creations. Cereal milling, often overshadowed in the shadow of baking and cooking, is an extraordinary blend of art and science, where traditional techniques meet modern technology. This article explores the fascinating journey of grains as they undergo meticulous grinding, revealing the delicate interplay of physics, chemistry, and craftsmanship that shapes our food. Join us as we delve into the world of milling, uncovering its storied history, the diverse methods employed by millers, and the significance of this age-old practice in our modern diets. From the field to the millstone, discover how the grinding of grain not only nourishes our bodies but also enriches our culture and sustains our communities.

Understanding the Milling Process: From Farm to Flour

The journey from golden grains in the fields to the finely milled flour found in our kitchens is a meticulous process that embodies both tradition and technological advancement. Harvesting initiates this journey, where the grain is collected at its peak ripeness, ensuring maximum flavor and nutrition. Following this, cleaning is vital, removing dirt, stones, and other impurities to yield high-quality grains. Next, the grains are conditioned to prepare them for milling; this involves adjusting moisture levels to achieve the desired texture and quality. The final step in this preparatory phase is tempering, which strengthens the grain’s outer layer, making it easier to separate during milling.

Milling itself is a blend of art and science, transforming the prepared grains into flour through a series of processes. The key stages include grinding, where grains are crushed between heavy stones or steel rollers, and sifting, which separates flour particles based on size. These stages allow for precise control over the fineness of the flour—a crucial aspect for bakers who often require various types of flour tailored to specific recipes. The resulting flour is then packaged and distributed, ready to fuel countless culinary creations around the world. Below is a simplified overview of the milling process:

| Stage | Description |

|---|---|

| Harvesting | Collecting ripe grains from fields |

| Cleaning | Removal of impurities and foreign materials |

| Conditioning | Adjusting moisture content for ideal milling |

| Milling | Grinding grains into flour through various methods |

| Sifting | Separating flour particles by size |

The Role of Equipment and Technology in Modern Cereal Milling

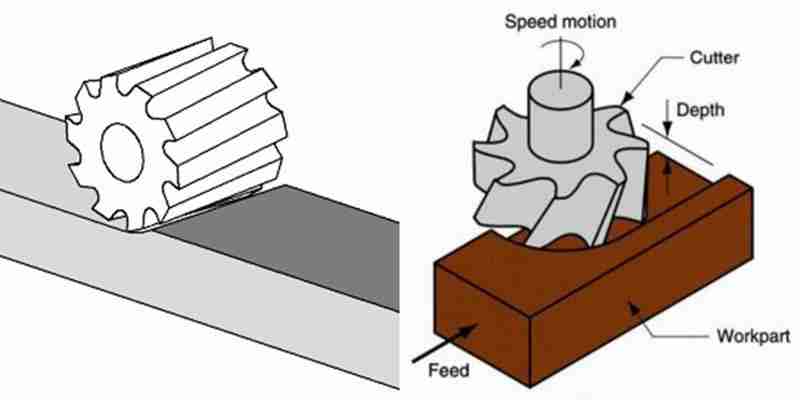

The modern cereal milling process blends artistic precision with cutting-edge technology to transform raw grains into the finely ground products we rely on. Advanced machinery, such as roller mills and stone grinders, plays a crucial role in achieving consistent particle size and superior flour quality. Automated systems ensure efficiency and accuracy, while sensors and software monitor parameters such as moisture content and temperature, preventing spoilage and ensuring optimal extraction rates. This synergy of traditional methods and technological innovations helps millers produce a diverse range of products, from whole grain flours to specialty mixes tailored for specific baking needs.

The integration of technology extends beyond the milling process itself; it also streamlines operations and enhances overall productivity. For instance, computerized control systems manage flow rates and energy consumption, while data analytics provide insights for process optimization. Here’s a simple overview of key equipment and technology used in modern milling facilities:

| Equipment/Technology | Function |

|---|---|

| Roller Mills | Crush and grind grains to desired coarseness |

| Air Classifiers | Separate particles by size for uniformity |

| Dust Collection Systems | Ensure a clean workspace and maintain air quality |

| Quality Control Systems | Monitor and maintain product standards |

Each piece of equipment plays a vital role in creating the final product, showcasing how technology not only preserves the tradition of cereal milling but also propels it into a future of innovation. Together, these advancements allow millers to respond to consumer demands with agility and creativity, ensuring that even the simplest loaf of bread carries the hallmark of careful craftsmanship and technological excellence.

Nutritional Considerations: Maximizing Benefits Through Milling Techniques

Understanding the nutritional implications of cereal milling is pivotal in enhancing the health benefits of Grains. Various milling techniques not only affect the texture and taste of the final product but also play a crucial role in preserving or enhancing its nutritional content. Different milling processes can result in variances in the levels of essential nutrients, including vitamins, minerals, and fiber. By selecting the appropriate milling techniques, millers can optimize the availability of these critical components:

- Stone Milling: This traditional method keeps more of the grain’s natural nutrients intact due to lower heat generation.

- Cold Milling: Minimizes nutrient loss by avoiding high temperatures, preserving delicate compounds like B vitamins.

- Roller Milling: Highly efficient but can strip away the bran and germ, necessitating fortification to regain lost nutrients.

Moreover, the particle size of the flour can influence its digestibility and nutritional absorption. For instance, finer flours might be easier to incorporate into various baking recipes but can lead to a diet lower in fiber if whole grains are improperly processed. Below is a comparison table highlighting key attributes of different milling methods:

| Milling Technique | Typical Nutritional Retention | Ideal Uses |

|---|---|---|

| Stone Milling | High | Breads, Whole grain products |

| Cold Milling | Very High | Baking, Specialty flours |

| Roller Milling | Moderate | All-purpose flour, Pastries |

By carefully considering these aspects, consumers and producers alike can make informed choices that not only enhance the flavor and texture of cereals but also ensure that the essential nutrients remain well-preserved for maximum health benefits.

Sustainability in Milling: Practices for a Greener Grain Industry

Embracing sustainability in cereal milling is not merely an option; it has become an essential pursuit for millers aiming to reduce their environmental footprint. By implementing energy-efficient technologies, mills can significantly lower their energy consumption and greenhouse gas emissions. This involves integrating renewable energy sources, like solar or wind, to power operations. Moreover, the choice of raw materials plays a crucial role—millers are increasingly sourcing grains from local, organic farms to minimize transportation impact and support sustainable agriculture. The goal is to create a closed loop within the milling process that prioritizes resource conservation and ecological balance.

Another approach to enhancing sustainability involves optimizing water use and waste management practices. Mills can adopt water recycling systems that reduce overall consumption and minimize wastewater. Alongside this, implementing zero-waste strategies can transform by-products, such as bran or germ, into valuable ingredients for other industries, including animal feed or health supplements. Consider the following practices as benchmarks for sustainability in milling:

| Practice | Impact |

|---|---|

| Renewable Energy Adoption | Reduces carbon footprint |

| Local Sourcing of Grains | Lowers transportation emissions |

| Water Recycling Systems | Conserves fresh water resources |

| Zero-Waste Initiatives | Maximizes resource use and efficiency |

Millers who prioritize such sustainable practices not only contribute positively to the environment but also enhance their marketability. Consumers increasingly seek eco-friendly products, and certifications verifying sustainable practices can improve brand loyalty. As more mills integrate these environmentally conscious methods, the grain industry will continue to shift towards greener, more sustainable operations, paving the way for a future where both grain quality and ecological integrity can thrive together.

The Way Forward

As we conclude our exploration of “Grinding the Grain: The Art and Science of Cereal Milling,” it becomes clear that this ancient practice is as much an art as it is a science. The precision of modern milling techniques harmonizes with age-old traditions to produce the flours that nourish our daily lives. Each grain, with its unique attributes, undergoes a meticulous journey, transformed through the tireless dance of machinery and the skilled hands of millers who have honed their craft over generations.

In the world of cereal milling, the seemingly simple act of grinding grain reveals a complex interplay of chemistry, physics, and artistry. From the choice of grain to the intricacies of the milling process, every decision shapes the final product in ways that affect taste, texture, and nutrition. Whether you’re a baker seeking the perfect flour for your next creation or a consumer fascinated by the journey of your food, understanding the milling process enhances our appreciation for the ingredients we often take for granted.

As we embrace the future of food production, it is essential to remember the rich history and innovative science behind cereal milling. The grains that start their journey in the fields, through skilled milling, evolve into the foundation of countless culinary delights. So, the next time you sift through a bag of flour, remember the art and science that brought it from field to table, and perhaps, consider how you might contribute your own chapter to the ongoing story of cereal milling.