In the heart of agricultural innovation, a new chapter is unfolding for the rice industry with the unveiling of the 2-ton Rice Mill Plant Project. As global demand for rice continues to grow, so too does the need for efficient processing techniques that can elevate both yield and quality. This ambitious initiative seeks to transform raw grains into polished, market-ready products while promoting sustainable practices in rice cultivation. With cutting-edge technology and a vision for enhanced productivity, the 2-ton rice mill plant stands at the forefront of a movement that not only empowers local farmers but also redefines the grains industry in the modern age. In this article, we will explore the intricate details of this project, its anticipated impact on the agricultural landscape, and the broader implications for food security and economic development in rice-producing regions.

Unveiling Innovation in Agriculture Technology

In a groundbreaking initiative aimed at revolutionizing rice production, the newly unveiled 2-ton rice mill plant promises to enhance efficiency and sustainability in the agricultural sector. Designed with cutting-edge technology, this mill is set to address the pressing challenges faced by farmers, particularly in rural areas. By integrating eco-friendly practices and advanced processing methods, the mill not only increases yield but also minimizes waste. Key features include:

- Automated milling processes that ensure precision and consistency.

- Energy-efficient operations to reduce skyrocketing energy costs.

- Mobile app connectivity for monitoring production in real-time.

This initiative goes beyond mere production; it is a step towards community empowerment. By providing local farmers with access to this modern milling facility, the project aims to boost local economies while ensuring that high-quality rice is readily available in markets. Furthermore, a transparent pricing model assures farmers that they can reap the benefits of their hard work without falling victim to market volatility. This innovative approach marks a significant leap in making agricultural practices smarter and more responsive to the needs of the community. Below is a concise comparative overview of traditional vs. modern milling techniques:

| Feature | Traditional Milling | Modern Milling |

|---|---|---|

| Processing Time | Long | Short |

| Yield Efficiency | Low | High |

| Waste Generation | High | Minimal |

| Technology Use | Manual | Automated |

Maximizing Efficiency: The Operational Blueprint of the Rice Mill

Operating a rice mill efficiently hinges on a thoughtful assembly of processes and technologies. At the core of our strategy is the seamless integration of advanced machinery designed to optimize every stage of production, from harvesting to milling. By embracing automated systems, we minimize manual labor while enhancing precision, leading to higher output rates. Key components of our operational blueprint include:

- High-capacity threshers: These machines ensure rapid separation of rice grains from husks, significantly reducing the time required for initial processing.

- Precision milling equipment: This guarantees uniformity in grain size and minimizes breakage, which is crucial for maintaining quality.

- Efficient drying systems: Controlled moisture content prevents spoilage and enhances storage lifespan.

In addition to our machinery, data-driven management practices play a vital role in maximizing productivity. By utilizing real-time monitoring systems, we can track performance metrics and adjust operations accordingly, ensuring we respond dynamically to any inefficiencies. Our key performance indicators (KPIs) include:

| Indicator | Description | Target |

|---|---|---|

| Output Rate | Metric tons of rice processed per hour | 2.5 |

| Downtime | Percentage of time machines are not operational | Below 5% |

| Quality Yield | Proportion of whole grains to broken grains | Above 90% |

Sustainable Practices in Grain Processing and Their Impact

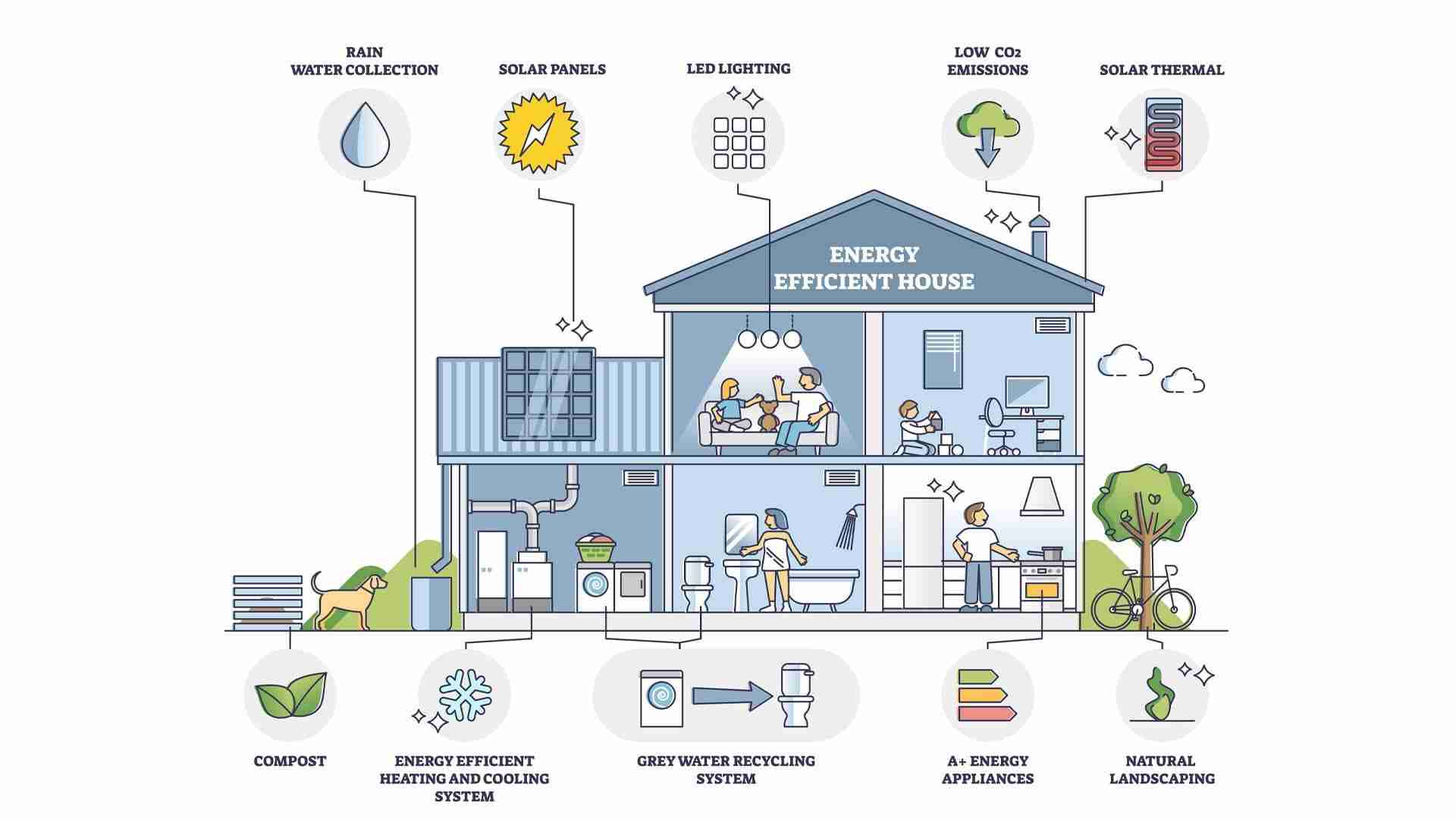

The implementation of sustainable practices in grain processing offers numerous benefits, both for the environment and for local economies. Advanced techniques, such as low-emission drying systems and water-efficient milling processes, help reduce the carbon footprint of rice production. By integrating renewable energy sources, such as solar panels and biomass energy, milling operations can significantly decrease reliance on fossil fuels. This not only lowers operational costs but also promotes a healthier ecosystem by minimizing pollutants that typically escape into the environment. Additionally, employing closed-loop water systems conserves precious water resources and prevents contamination, further enhancing sustainability in grain processing.

Moreover, the introduction of transparent supply chains ensures that sustainable practices lead to fair trade and equitable livelihoods for local farmers. By focusing on the traceability of grains, stakeholders can encourage environmentally responsible farming methods while guaranteeing fair prices for producers. Education and outreach programs foster community involvement in sustainable practices, setting the stage for a shared commitment to protecting natural resources. The following table highlights key sustainable practices and their impacts:

| Practice | Impact |

|---|---|

| Low-Emission Drying | Reduces CO2 emissions |

| Water-Efficient Milling | Conserves water resources |

| Renewable Energy Utilization | Minimizes reliance on fossil fuels |

| Closed-Loop Systems | Prevents water contamination |

Future Prospects: Market Opportunities and Community Benefits

The unveiling of the 2-ton rice mill plant project presents numerous avenues for market expansion, positioning interested stakeholders to capitalize on growing demands in both local and international markets. With rice being a staple food for millions globally, the establishment of this facility aims to not only streamline production but also bolster efficiency within the supply chain. Key market opportunities include:

- Expansion into untapped regions with high rice consumption

- Collaboration with agricultural enterprises to enhance grain quality

- Introduction of value-added products, such as rice bran oil and flour

- Partnerships with local farmers to ensure sustainable sourcing

Beyond market growth, the rice mill plant comes with substantial community benefits that will resonate deeply with local stakeholders. As this project rolls out, it is set to create numerous job opportunities, thus reducing unemployment and fostering economic growth. Furthermore, community engagement will be enhanced through:

- Skill development programs for local labor

- Investment in local infrastructure through plant operations

- Accessibility to premium quality rice, improving local diets

- Strengthening of farmer cooperatives for better yields

To illustrate the anticipated economic impact, the table below summarizes projected benefits:

| Benefit | Estimated Impact |

|---|---|

| Jobs Created | 50+ Full-Time Positions |

| Annual Rice Production | 400 Tons |

| Investment in Local Economy | $250,000+/Year |

Insights and Conclusions

As we conclude our exploration of the innovative 2-ton rice mill plant project, it becomes evident that this initiative is more than just a stepping stone for modern agriculture; it represents a profound shift towards sustainability and efficiency in grain processing. By harnessing advanced technology and sustainable practices, this project not only aims to increase rice production but also empowers local farmers, fosters economic growth, and enhances food security.

With its meticulously designed operations and commitment to quality, the rice mill stands as a testament to the possibilities that arise when tradition meets innovation. As the project unfolds, it will be fascinating to witness its impact on communities and the agricultural landscape as a whole.

In a world where food production needs to evolve in response to growing populations and changing climates, the unveiling of the 2-ton rice mill plant heralds a promising chapter in the journey of turning grains into not just nourishment, but a catalyst for development. As we move forward, let us keep an eye on such endeavors that weave together sustainability, technology, and community aspirations—a reminder that the future of agriculture may indeed be in our hands.