In the ever-evolving landscape of agricultural technology, the quest for efficiency stands as a paramount goal for farmers and producers alike. Enter the remarkable world of combined rice mill machines—an innovation that marries functionality with speed, transforming the once labor-intensive process of rice milling into a seamless operation. These machines, which integrate multiple milling functions into a single unit, not only streamline production but also enhance the quality of the final product. In this article, we will explore the wonders of combined rice mill machines, examining how they are unlocking new levels of efficiency in rice processing, reducing waste, and empowering farmers to meet the growing global demand for this staple crop. Join us as we delve into the mechanics, benefits, and future potential of this technological marvel that is changing the face of rice milling.

Enhancing Productivity Through Integrated Technology

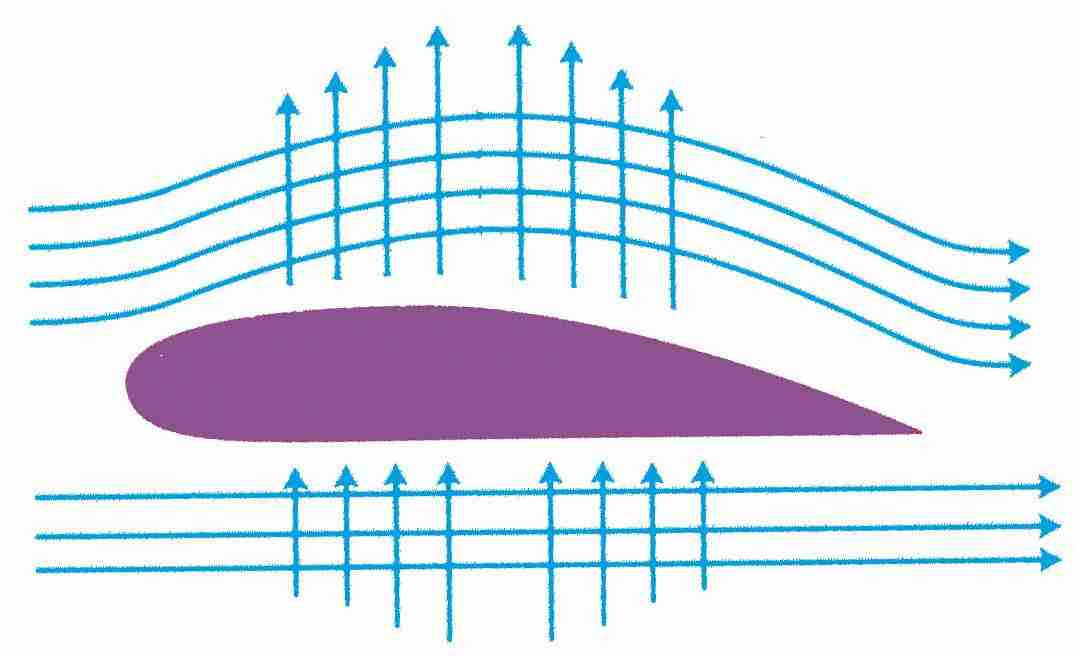

In the modern agricultural landscape, the integration of technology has revolutionized traditional processes, particularly in rice milling. By combining multiple functions into a single machine, farmers can significantly reduce the time and workforce required for milling operations. These combined rice mill machines offer the ability to perform several tasks such as husking, whitening, and polishing in one seamless operation, minimizing the need for multiple devices and enhancing overall productivity. As a result, farmers can focus on other critical aspects of their businesses, leveraging the time saved to explore new markets or improve crop yields.

The advantages of utilizing integrated machinery extend beyond mere time savings. By adopting these advanced systems, users can effectively cut down on operational costs and reduce energy consumption. Key benefits include:

- Streamlined Processes: With fewer machines involved, the risk of technical disruptions is minimized.

- Quality Control: Integrated systems allow for precise adjustments, ensuring that each batch of rice meets high-quality standards.

- Space Efficiency: Integrating multiple functionalities into one compact unit frees up valuable space in production facilities.

The impact of integrated technology is further highlighted in productivity metrics, showcasing its potential to transform rice milling into a more efficient and sustainable practice. The following table summarizes some key features of leading combined rice mill machines:

| Machine Model | Husking Rate (kg/h) | Power Requirement (kW) | Features |

|---|---|---|---|

| EcoMill 3000 | 1500 | 5.5 | Energy-efficient, Low noise |

| RiceMaster Pro | 2000 | 7.5 | Auto-cleaning, Adjustable settings |

| SustainMiller 500 | 1800 | 6.0 | Solar-compatible, Compact design |

The Economic Benefits of Combined Rice Mill Machines

The economic landscape of rice production is evolving rapidly, particularly with the rise of advanced agricultural technologies such as combined rice mill machines. These machines stand out for their ability to streamline various processing stages, significantly reducing labor costs and enhancing productivity. By integrating multiple functions—from hulling to milling—these machines allow farmers and mill operators to save on operational expenses while maximizing output. As a result, the overall cost of rice production is lowered, leading to better profit margins for stakeholders.

Moreover, the adoption of combined rice mill machines positively impacts the broader economy. With enhanced efficiency, these machines can increase the supply of processed rice, meeting growing demand in local and international markets. Benefits include:

- Reduction in the need for extensive manual labor, freeing up workforce resources for other tasks.

- Decreased wastage during processing, as precision milling minimizes losses of grain.

- Improved quality of the final product, attracting more buyers and potentially commanding higher prices.

The ripple effect of these machines can be illustrated in a simple table format:

| Benefit | Impact on Economy |

|---|---|

| Lower Production Costs | Increased Profit Margins |

| Higher Efficiency | More Competitive Pricing |

| Improved Quality | Attraction of International Markets |

Streamlining Operations for Sustainable Agriculture

In the quest for sustainable agriculture, the adoption of innovative machinery plays a pivotal role. Combined rice mill machines stand at the forefront, offering not just efficiency but also a pathway to reduced environmental impact. These machines integrate multiple processes, such as husking, milling, and polishing, into a single unit. By consolidating these operations, farmers can optimize their workflow, save precious time, and minimize the energy required for rice processing. The benefits extend beyond efficiency; they contribute to a reduction in waste, as fewer materials are lost during the milling process.

Furthermore, embracing technology in rice milling paves the way for smarter resource management. With real-time data and automated controls, rice mill operators can monitor performance metrics that aid in decision-making. Key advantages include:

- Reduced Labor Costs: Automation decreases the need for manual intervention.

- Enhanced Product Quality: Consistent processing results in better quality rice.

- Lower Energy Consumption: Streamlined operations require less energy, aligning with sustainability goals.

To illustrate the operational impact, consider the following comparison of traditional milling versus combined machines:

| Feature | Traditional Milling | Combined Rice Mill Machines |

|---|---|---|

| Processing Time | Longer | Shorter |

| Energy Usage | Higher | Lower |

| Waste Produced | Higher | Reduced |

By integrating these advanced machines into their practices, farmers are not only enhancing their productivity but also building a more sustainable future for agriculture, where efficiency and environmental responsibility go hand in hand.

Choosing the Right Combined Rice Mill for Your Needs

When selecting a combined rice mill, several factors play a crucial role in ensuring that the machine meets your operational demands. Capacity is one of the primary considerations; investing in a model that aligns with your production needs can prevent bottlenecks. Additionally, look for features such as energy efficiency, which not only conserves resources but can also significantly reduce operational costs. Other important characteristics to evaluate include the durability of materials used in construction and the ease of maintenance, as these will affect the longevity and performance of your equipment.

Furthermore, understanding the available technology options is essential for making an informed choice. Many modern combined rice mills come equipped with advanced features such as auto-cleaning systems, integrated grading mechanisms, and user-friendly interfaces that help streamline operations. Consider the after-sales support provided by manufacturers, as reliable service and readily available spare parts can make a substantial difference in your machine’s upkeep. Below is a brief table highlighting some vital specifications to consider:

| Specification | Importance |

|---|---|

| Capacity (kg/h) | Determines production efficiency |

| Energy Consumption | Affects operational costs |

| Maintenance Requirements | Impacts downtime and longevity |

| Technology Features | Enhances usability and effectiveness |

Wrapping Up

the advancement of combined rice mill machines represents a significant stride towards optimizing rice milling operations. These machines not only streamline processes but also ensure a higher quality of output, catering to the demands of a rapidly evolving agricultural landscape. As we stand at the intersection of tradition and technology, the wonders of these innovative machines unveil a path towards greater efficiency and sustainability in rice production. By embracing these solutions, farmers and millers alike can unlock new levels of productivity, reduce waste, and ultimately contribute to the global food supply with renewed vigor. As the industry continues to evolve, the potential for further advancements in milling technology promises an exciting future for rice cultivation and processing, where efficiency reigns supreme.