Grinding Potential: The Art and Science of Maize Milling

In the heart of countless cultures and kitchens around the world lies a staple that transcends borders and binds generations: maize. This versatile grain, revered for its nutritional value and culinary flexibility, has seamlessly woven itself into the fabric of daily life. But before it graces our tables as tortillas, polenta, or cornbread, maize must undergo a transformational journey—one that is both an art and a science. Welcome to the intricate world of maize milling, where ancient traditions meet modern innovations, and the grinding potential of a simple kernel is harnessed with precision and care. In this exploration, we will delve into the techniques, technologies, and cultural significance that define maize milling, revealing not just how the grain is processed, but also why it remains an essential ingredient in our global culinary heritage. Join us as we uncover the elements that contribute to the perfect grind, celebrating the balance between craftsmanship and technology that ensures maize continues to nourish and inspire.

Exploring the Anatomy of Maize: Understanding Kernel Composition and Properties

When delving into the intricacies of maize, we uncover a rich tapestry of components that define kernel structure and influence its milling characteristics. The kernel is primarily composed of three main parts: the pericarp, the endosperm, and the germ. Each of these components plays a pivotal role in determining not only the nutritional profile of maize but also its behavior when subjected to milling processes. The pericarp, or outer layer, protects the seed, while the endosperm serves as the primary source of energy and is crucial for flour yield during milling. Lastly, the germ is packed with oils and proteins, contributing to both flavor and the overall quality of the milled product.

Understanding the composition of these elements is essential for optimally milling maize, as each part interacts uniquely under mechanical stress. Factors such as moisture content, kernel hardness, and grinding method can significantly affect the overall outcome of maize milling. Here’s a brief overview of the key properties impacting milling:

| Property | Impact on Milling |

|---|---|

| Moisture Content | Affects grinding efficiency and product shelf life. |

| Kernels’ Hardness | Determines the energy required for effective milling. |

| Grinding Method | Influences particle size and overall conversion rate. |

By understanding these kernel properties, millers can tailor their techniques to enhance the yield and quality of ground maize products, ensuring that the nutritional and sensory attributes are preserved in the final product. Every grain tells a story, revealing the blend of biological design and applied technology that culminates in the art of milling.

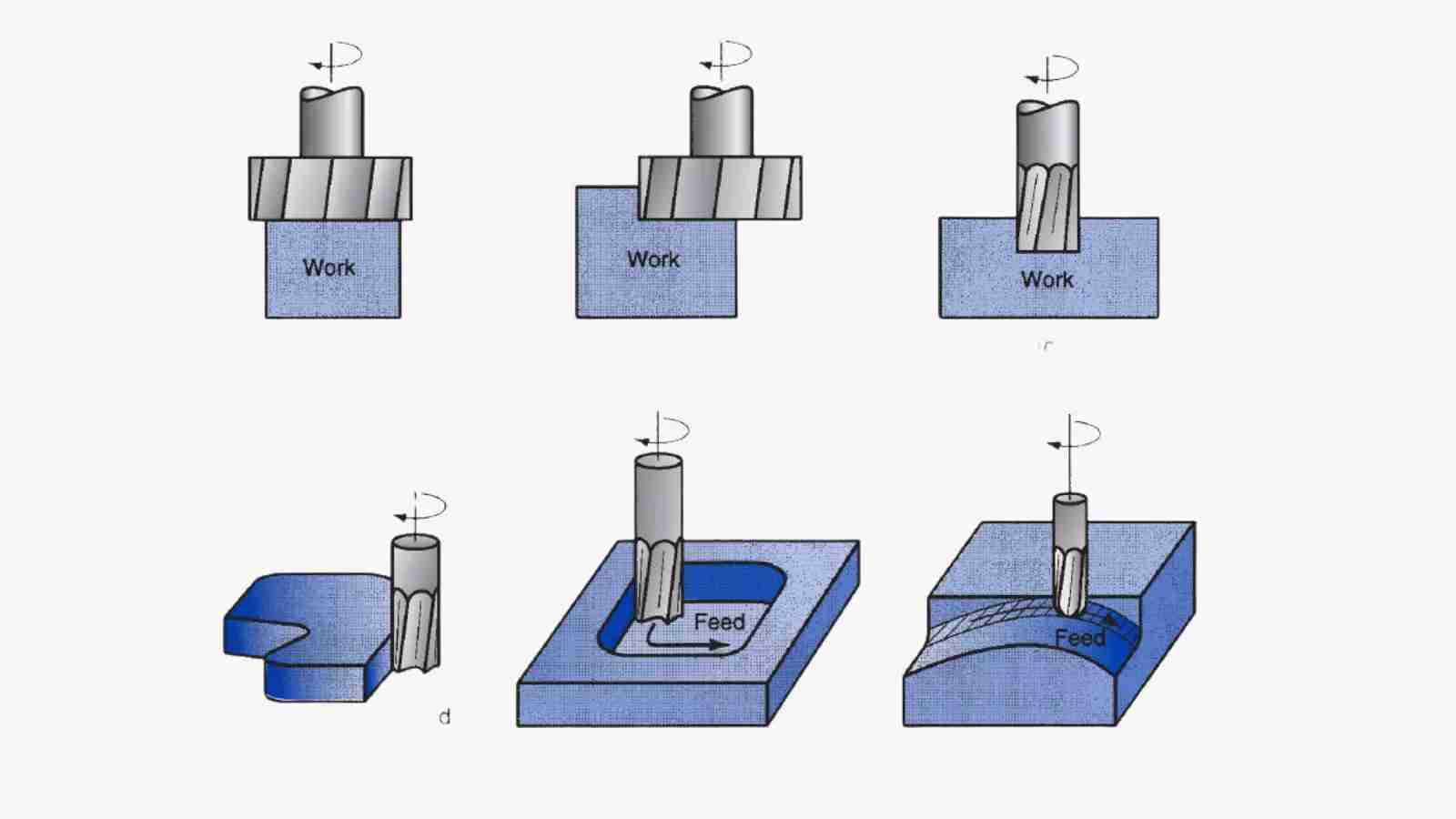

The Milling Process Unveiled: Techniques for Optimizing Grain Extraction

The milling process is an intricate dance between art and science, where each technique plays a pivotal role in enhancing grain extraction. At the heart of successful maize milling lies the careful selection of equipment and methods. Modern mills utilize a variety of grinding techniques that maximize yield while maintaining the integrity of the grain. Among these techniques, stone milling and steel roller milling stand out. Stone milling is revered for its ability to produce flour rich in flavor and nutrients, largely due to the gentle grinding action that preserves the grain’s natural oils. Conversely, steel roller milling allows for higher extraction rates and finer flour, making it ideal for mass production.

To further optimize grain extraction, several key factors must be considered:

- Moisture Content: Maintaining the right balance of moisture helps in achieving better separation during milling.

- Particle Size Distribution: A well-defined particle size improves the milling efficiency and consistency of the final product.

- Grinding Speed: Adjusting the speed can affect both the heat generated and the grinding action, impacting extraction rates.

Moreover, an essential element in determining the effectiveness of the milling process is the preconditioning of the grain. By allowing the grain to absorb moisture prior to milling, it softens the endosperm while maintaining the strength of the bran layer. This treatment not only facilitates easier processing but also enhances flour quality. The interplay between these factors ultimately leads to optimized grain extraction that caters to consumer demands for both quality and quantity.

Quality Control in Maize Milling: Best Practices for Ensuring Consistency

Ensuring consistency in maize milling requires a comprehensive approach that emphasizes both the art and the science behind the process. One fundamental aspect of quality control is continuous monitoring of grain inputs. Regularly testing the moisture content, kernel hardness, and overall grain quality is essential, as these factors significantly influence milling performance and flour consistency. Additionally, implementing a robust screening process helps in separating debris from the maize, ensuring that only quality grains enter the milling system. This foundation fosters an optimal environment for achieving the desired milling outputs.

Another key practice is the calibration of milling equipment to maintain uniform particle size distribution, which directly impacts the flour’s performance in culinary applications. Operators should engage in periodic evaluations of the milling machinery, examining factors such as grinding speed, roll gap, and milling pressure. Regular maintenance schedules and systematic performance audits not only enhance equipment longevity but also safeguard the consistency of the end product. Below is a concise overview of essential quality control measures:

| Quality Control Measure | Description |

|---|---|

| Grain Quality Assessment | Check moisture, hardness, and overall quality. |

| Regular Equipment Calibration | Adjust milling parameters for uniformity. |

| Screening Process | Eliminate impurities before milling. |

| Performance Audits | Evaluate machinery and outputs regularly. |

Innovative Approaches to Sustainable Milling: Reducing Waste and Enhancing Efficiency

As the global demand for maize flour continues to rise, innovative milling techniques are becoming increasingly essential for steering the industry towards sustainability. By integrating cutting-edge technologies, mills can minimize waste while maximizing output. Initiatives like sensor automation are revolutionizing the milling process, enabling real-time monitoring of equipment and grain quality. This not only enhances operational efficiency but also ensures that by-products, such as husks and germ, can be repurposed for animal feed or bioenergy, thereby fostering a circular economy.

Moreover, new milling methods, such as dry milling, present a host of environmental advantages over traditional wet processes. For instance, they significantly reduce water usage and energy consumption. The optimization of flour extraction rates also plays a critical role; it allows millers to produce a higher yield from the same quantity of maize. To illustrate the efficiency of modern milling techniques, the following table summarizes key metrics comparing conventional and innovative milling methods:

| Method | Water Usage (liters/kg) | Energy Consumption (kWh/kg) | Yield (% of grain) |

|---|---|---|---|

| Traditional Milling | 15 | 2.5 | 70 |

| Dry Milling | 1 | 1.2 | 85 |

Final Thoughts

As we conclude our exploration of “Grinding Potential: The Art and Science of Maize Milling,” it becomes evident that this age-old practice is a harmonious blend of tradition and innovation. From the simple, rhythmic turns of a hand-cranked millstone to the sophisticated machinery that defines modern milling, each method reveals a profound connection between human ingenuity and the natural world. The transformation of maize into flour and meal is not merely a technical process; it is an intricate dance of science, precision, and artistry.

In understanding the nuances of grinding potential, we uncover not only the physical attributes of maize kernels but also the cultural significance they hold across various societies. As we adapt to new technologies and approaches, the essence of maize milling remains rooted in a respect for the grain and the generations that have perfected its use.

As we move forward, let us continue to appreciate the symphony of flavors and textures that beautifully emerge from this craft, reminding us of the rich tapestry of life that maize has woven through history. The journey of maize milling is both an ancient tradition and a burgeoning field, inviting all of us to partake in its evolution. Whether you are a miller, a chef, or simply a curious food enthusiast, there is always more to discover in every kernel, every grind, and every dish that celebrates this humble yet remarkable grain.