Introduction: Crafting a Crunch: The Art and Science of Cereal Processing

In the early morning light, the ritual begins—an unassuming bowl, a splash of milk, and the all-too-familiar rustle of cereal as it tumbles in. Each spoonful crunches with its own unique symphony, a testament to the intricate dance between nature and technology. But have you ever paused to wonder about the journey your breakfast has taken? Beyond the colorful packaging and enticing advertisements lies a world where art and science converge in the meticulous craft of cereal processing. In this exploration, we will unravel the complex layers that define the crunch, from the grains harvested at sunrise to the high-tech processing plants where they undergo transformation. Join us as we delve into the delicate balance of flavors, textures, and nutritional advancements that craft our beloved cereals, turning simple grains into iconic breakfast staples. Whether you’re a casual consumer, a food enthusiast, or a curious mind, this article invites you to discover the fascinating craftsmanship behind every crispy bite.

Exploring the Texture Spectrum: Understanding the Importance of Crunch in Cereals

The texture of cereals, particularly crunch, plays a crucial role in shaping the overall eating experience. This delightful auditory sensation not only enhances palate appeal but also influences consumer behaviors. The relationship between crunch and satisfaction can be attributed to various factors, including ingredient composition, processing techniques, and moisture content. Achieving that perfect crunch involves a careful balance of ingredients, temperature control, and timing in the processing stage. This intricate dance of science and art transforms simple grains into a multisensory experience that delights both taste buds and ears alike.

When evaluating the significance of crunch in cereals, it is essential to recognize how different types of processing affect texture. Factors that contribute to achieving that ideal crunchy consistency include:

- Extrusion: A high-temperature, high-pressure method that creates texture through mechanical and thermal processes.

- Toasting: A technique that caramelizes sugars and enhances flavor while adding a satisfying snap.

- Drying: Reducing moisture levels is critical; excess moisture can lead to a chewy rather than crunchy texture.

Understanding these techniques enables manufacturers to tailor their products to meet consumer preferences. The following table highlights popular cereal types and their respective crunch levels, reflecting the diversity found in the cereal market:

| Cereal Type | Crunch Level | Texture Characteristics |

|---|---|---|

| Granola | High | Chunky, crispy clusters. |

| Puffed Rice | Moderate | Light, airy with a subtle snap. |

| Flakes | Low | Delicate, mildly crunchy. |

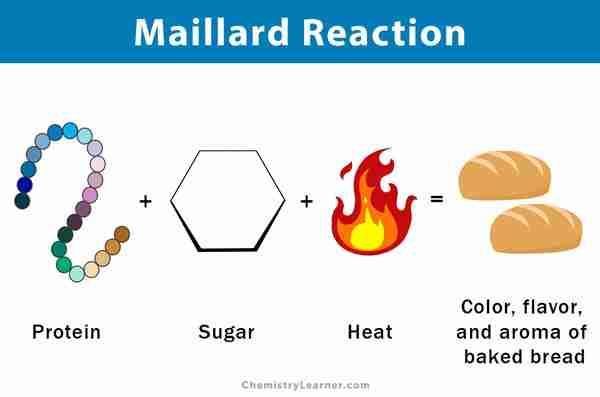

The Maillard Reaction Unveiled: Crafting Flavor and Color in Cereal Production

The transformation of grains into beloved breakfast cereals is not merely a mechanical process; it involves a delicate dance of chemistry and artistry. Among the myriad of reactions that occur during processing, the Maillard reaction takes center stage, enchanting our taste buds with its complexity. As cereals are toasted or cooked, reducing sugars and amino acids react under heat, resulting in a symphony of flavors and aromas. This intricate reaction is responsible for the alluring golden hue of toasted cereals, enticing consumers with their visual appeal and rich, savory scent. The balance of temperature and time plays a crucial role in this alchemical transformation, as slight deviations can yield dramatically different flavors – from nutty and sweet to deep and robust.

Moreover, understanding the stages of the Maillard reaction can aid cereal manufacturers in optimizing both flavor and nutritional value. The table below illustrates the key stages and resulting characteristics, showcasing how meticulous control over this reaction can enhance the quality of breakfast cereals:

| Stage of Maillard Reaction | Temperature Range (°C) | Flavor Characteristics |

|---|---|---|

| Initial Browning | 120-140 | Sweet and Light |

| Golden Phase | 140-160 | Nuts and Caramel |

| Savory Peak | 160-180 | Rich and Complex |

At the heart of cereal flavor development is the mastery of these stages, where scientists and food artisans collaborate to evoke appetizing notes that resonate with pride and nostalgia. Beyond the taste, the Maillard reaction contributes to mouthfeel, providing that crunchy texture that perfectly complements the flavors. The intimacy of science and culinary craft ensures that each bite of cereal is not just a meal; it’s an experience crafted through the magic of chemistry.

Innovative Ingredients: Enhancing Crunch through Nutritional Additives and Flavorings

The quest for the perfect crunch in cereals is not only a matter of texture but also of innovation and nutrition. By incorporating unique nutritional additives and carefully selected flavorings, manufacturers are able to enhance the eating experience significantly. Some popular ingredients include:

- Whole Grains: Unlocking natural crunch while boosting fiber content.

- Seeds and Nuts: Introducing satisfying texture and healthy fats.

- Protein Isolates: Adding density without sacrificing crispness.

- Natural Sweeteners: Elevating flavor profile while maintaining a healthy twist.

Flavorings play an equally pivotal role in the overall sensory experience of cereals. By using natural extracts and spices, manufacturers are crafting innovative flavor combinations that captivate consumers. Consider these trending flavor enhancer approaches:

| Flavor | Description |

|---|---|

| Maple Infusion | Delivers a rich, sweet experience reminiscent of breakfast favorites. |

| Spicy Cinnamon | Adds warmth and depth, perfect for an adventurous palate. |

| Berry Blast | A tart and fruity explosion that offers both flavor and visual appeal. |

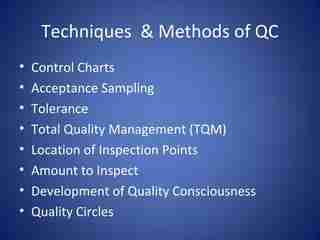

Quality Control Techniques: Ensuring Consistency in Crunch Across Production Batches

Achieving a consistent crunch in cereal production is an intricate blend of art and science, necessitating the implementation of various quality control techniques throughout the manufacturing process. One primary focus is on ingredient selection, where factors such as moisture content, particle size, and freshness are meticulously monitored. By utilizing real-time monitoring systems, manufacturers can ensure that the raw materials meet the stringent standards required for optimal crunchiness. Additionally, batch testing becomes crucial, involving rigorous evaluations of samples from each production batch, where attributes like texture, flavor, and color are assessed to ensure uniformity across the final product.

Moreover, controlling the cooking and drying phases of cereal processing significantly impacts crunchiness. Here are some techniques employed to guarantee consistency:

- Temperature Regulation: Maintaining specific temperature profiles during cooking ensures an even transformation of ingredients.

- Moisture Management: Monitoring moisture levels helps in optimizing the drying process, crucial for achieving the desired crunch.

- Time Controls: Strict timing for each phase of production is monitored to avoid discrepancies that could alter the final texture.

| Technique | Description |

|---|---|

| Sensor Technology | Utilizes sensors to track real-time changes in moisture and temperature. |

| Sample Testing | Regular sampling from production lines to ensure consistency in crunch |

| Feedback Loops | Incorporates feedback from consumer testing to refine product consistency. |

Closing Remarks

As we conclude our journey through the intricate world of cereal processing, we find ourselves at the intersection of art and science—a place where innovation meets tradition in the quest for the perfect crunch. From the fields of golden grains to the towering silos of factories, each phase of production is a careful orchestration of techniques, tailored flavors, and nutritional considerations.

Understanding the myriad processes involved not only enriches our appreciation for this breakfast staple but also empowers us as consumers to make informed choices about what we pour into our bowls each morning. As we savor the delightful textures and vibrant flavors that cereal has to offer, let us remember the mastery behind the scenes—the blend of expertise, creativity, and scientific principles that transform humble grains into the beloved crunch we know today.

Whether you’re a cereal connoisseur or simply someone who enjoys a quick bite, we hope this exploration has illuminated the fascinating mechanisms that bring your favorite cereals to life. The next time you enjoy that satisfying snap, crackle, and pop, take a moment to appreciate the complex fusion of art and science that makes it possible. After all, every crunch tells a story, and as we’ve discovered, it’s a story worth savoring.