In the heart of agrarian landscapes, where tradition meets technology, the future of rice milling is undergoing a remarkable transformation. Auto rice mills, once defined by their humble origins and manual operations, are now gearing up for a revolution that promises to enhance efficiency and quality in rice production. As global demands for food supply rise and the agricultural industry seeks ways to innovate, the integration of cutting-edge machinery, automated processes, and sustainable practices is setting a new standard. In this article, we will explore the emerging trends reshaping auto rice mills, the challenges they face, and the potential they hold to boost productivity while ensuring the integrity of this staple food. Join us as we delve into the world of rice milling—where automation meets agriculture, and tradition adapts to the promise of progress.

Innovative Technologies Transforming Auto Rice Mills

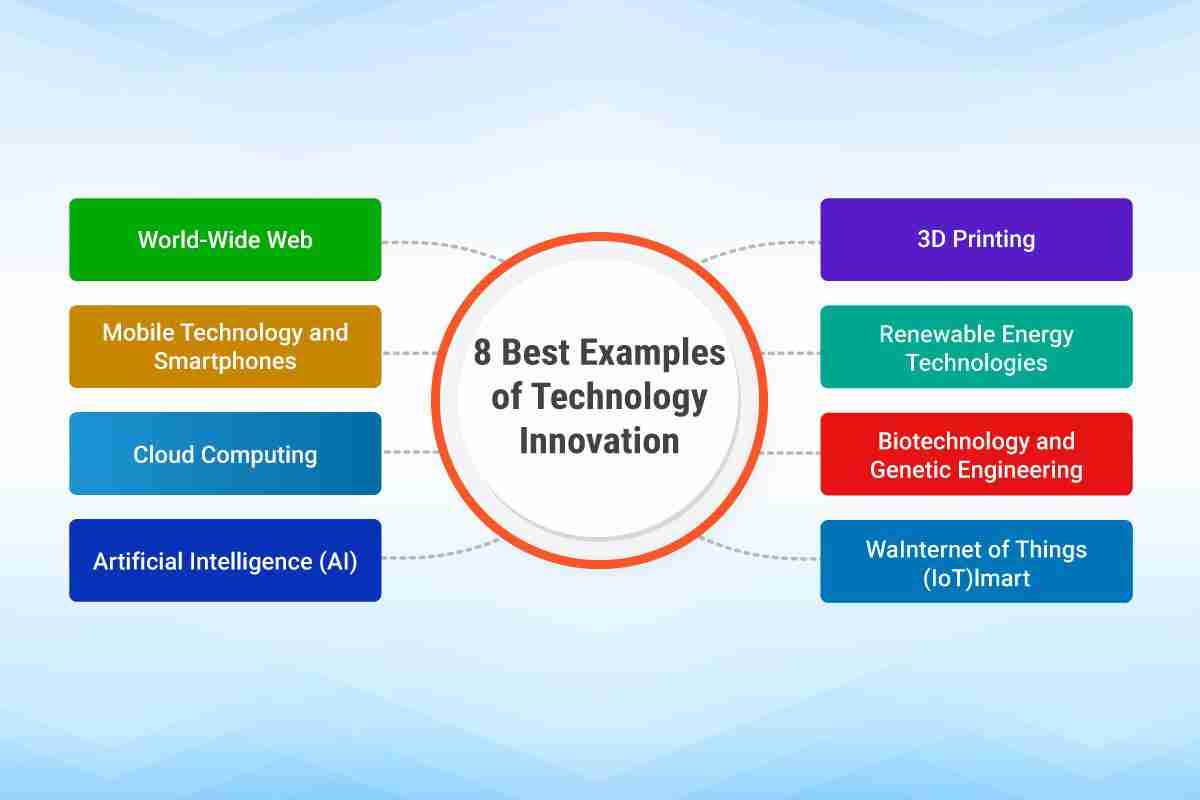

As the demand for rice continues to soar, innovative technologies are stepping in to streamline operations within auto rice mills. Automation plays a pivotal role, significantly reducing manual labor and increasing processing speed. Modern mills are now equipped with AI-driven systems that facilitate real-time monitoring and quality control, ensuring optimal output while minimizing waste. Additionally, smart sensors and IoT devices are transforming traditional workflow by collecting data that helps in predictive maintenance, thereby extending the lifespan of machinery and reducing downtime.

The advent of energy-efficient machinery is another exciting development in the sector, as it not only lowers operating costs but also contributes to sustainability goals. Equipment like mechanical separators, laser sorters, and high-capacity parboiling systems enhance product quality while maximizing throughput. Moreover, adopting cloud computing has allowed mill operators to analyze production metrics from anywhere, providing insights that drive decision-making and strategic planning. The integration of these technologies is setting a new standard for efficiency and productivity in the auto rice milling industry.

| Technology | Benefits |

|---|---|

| Automation | Reduces labor costs and increases speed |

| AI Systems | Improves quality control and optimizes output |

| Smart Sensors | Enables predictive maintenance |

| Energy-Efficient Machines | Lowers operating costs and enhances sustainability |

| Cloud Computing | Provides valuable data insights for decision-making |

Sustainable Practices for Enhanced Productivity

To unlock true efficiency in auto rice milling, integrating sustainable practices is paramount. These practices not only enhance productivity but also contribute to environmental preservation, ensuring that operations are both economically viable and ecologically friendly. Implementing energy-efficient machinery can significantly reduce the carbon footprint of rice mills. Furthermore, the use of renewable energy sources, such as solar panels or biogas installations, allows mills to become less dependent on traditional energy providers, leading to lower operational costs and increased profitability.

Additionally, adopting waste management strategies can transform potential liabilities into valuable resources. Mills can implement the following strategies to boost their sustainability footprint:

- Byproduct utilization: Convert rice husks and bran into biofuel or animal feed.

- Water recycling: Implement systems to capture and reuse wastewater in rice processing.

- Soil enrichment: Return organic waste back into the fields as fertilizer to support local farming communities.

Embracing these eco-conscious techniques not only strengthens the brand reputation of rice mills but also sets a precedent for the industry. As consumers become increasingly aware of sustainability, their preference for products from environmentally-responsible mills is likely to grow, creating an opportunity for enhanced market share and positioning in a competitive landscape.

Harnessing Data Analytics for Operational Excellence

In the realm of auto rice mills, effective data analytics can act as a catalyst for operational efficiency. By leveraging real-time data, mill operators can gain insights into every facet of their operations, from grain quality to processing times. This data-centric approach allows businesses to identify bottlenecks, optimize resource allocation, and enhance the overall production flow. Leading the charge in this digital transformation, a variety of tools and technologies can be implemented:

- Predictive Analytics: Anticipating machinery failures before they happen mitigates downtime, ensuring continuous operations.

- Supply Chain Optimization: Tracking inventory levels and demand patterns reduces waste and costs, enhancing profitability.

- Energy Consumption Monitoring: Analyzing energy use helps mills adopt sustainable practices while lowering operational expenses.

Moreover, the integration of data analytics fosters a culture of continuous improvement within rice mills. Implementing a centralized dashboard that showcases key performance indicators (KPIs) allows managers to make informed decisions swiftly. As a visual representation, consider the following table demonstrating potential KPIs and their impact on milling efficiency:

| KPI | Description | Impact |

|---|---|---|

| Production Yield | Amount of rice produced from raw grains | Informs quality control measures |

| Downtime Rate | Percentage of time machinery is non-operational | Drives maintenance scheduling |

| Energy Efficiency | Energy consumed per ton of rice processed | Affects operating costs and environmental impact |

By harnessing these data insights, auto rice mills not only enhance productivity but also pave the way towards a more sustainable and profitable future in the industry. This strategic utilization of data analytics prepares them for the challenges ahead while ensuring they remain competitive in an evolving market landscape.

Building a Resilient Supply Chain in the Rice Milling Industry

Ensuring a robust supply chain is critical for the auto rice milling industry, especially in the face of global uncertainties and shifting market demands. By diversifying sources for raw materials, manufacturers can mitigate risks associated with single-source reliance. This approach not only promotes supply chain resilience but also enhances the ability to respond swiftly to disruptions. Key strategies to consider include:

- Supplier Diversification: Engage multiple suppliers for each component to reduce dependence.

- Local Sourcing: Develop relationships with local farmers to minimize transportation costs and support sustainable practices.

- Technology Integration: Employ data analytics and IoT to better predict inventory needs and manage logistics effectively.

Furthermore, investing in flexible manufacturing systems can significantly improve responsiveness. Such systems allow mills to adapt production lines quickly to fluctuations in supply or demand, thus minimizing waste and optimizing output. Consider the following best practices:

| Best Practices | Description |

|---|---|

| Real-Time Monitoring | Implement sensors to track production processes and make adjustments as needed. |

| Inventory Management | Adopt just-in-time systems to keep inventory levels aligned with production rates. |

| Collaboration Platforms | Use technology to enhance communication among all supply chain participants. |

By embedding these practices in the operational framework, the rice milling industry can foster not only efficiency but also sustainability, ensuring long-term viability. Innovative approaches to supply chain management will pave the way for a resilient future in this pivotal sector.

Key Takeaways

the landscape of auto rice milling is on the cusp of a transformative era. As we explore the intersection of technology, sustainability, and efficiency, it becomes clear that the future of these mills is not merely about mechanization but about smart integration. Innovations such as AI-driven machinery, energy-efficient practices, and data analytics are set to empower farmers and millers alike, ensuring a more streamlined, profitable, and environmentally conscious rice production process.

As we rev up for the future, the race is not just towards higher yields but towards a resilient, sustainable agricultural ecosystem that values both quality and quantity. With each advancement, we stand on the brink of a new chapter in rice milling, one that promises to nourish communities while respecting our planet. As we continue this journey, it remains vital for stakeholders to embrace change, fostering collaboration and innovation for a brighter tomorrow in the auto rice milling industry. The road ahead is paved with possibilities, and together, we can cultivate a future that truly honors the grains that sustain us all.