In the verdant fields where rice paddies stretch toward the horizon, a silent transformation unfolds, shaping one of the world’s most vital staple foods. At the heart of this transformative process lies the often-overlooked yet essential Paddy Processing Unit. These facilities bridge the gap between the raw grains harvested from the earth and the polished rice that graces dining tables across continents. As global demands for food security escalate amidst growing populations, the importance of efficient and sophisticated processing techniques cannot be overstated. This article delves into the intricate workings of paddy processing units, exploring how they not only enhance the quality and accessibility of rice but also play a pivotal role in supporting local economies and sustainable agricultural practices. Join us as we uncover the intricate dance of machinery and expertise that ensures rice remains a cornerstone of nutrition and culture worldwide.

Evolving Techniques in Paddy Processing for Enhanced Quality

In the modern landscape of agriculture, the processing of paddy has witnessed a remarkable transformation, driven by the need for improved quality and efficiency. Innovative technologies and techniques have emerged, allowing for precise control over each stage of the processing cycle. Leading the charge are automated milling systems, which not only enhance productivity but also minimize damage to the grain. Additionally, the integration of digital monitoring systems enables processors to track key parameters such as moisture content and temperature, ensuring optimal preservation of the grain’s nutritional value. With advancements such as color sorting machines, processors can also achieve greater uniformity in appearance, ultimately elevating the market value of the final product.

Furthermore, sustainable practices have begun to permeate the paddy processing landscape, heralding a new era of eco-conscious production. Adopting integrated pest management and biological control methods are just a couple of ways facilities are reducing their environmental footprint. On the efficiency front, the introduction of energy-saving technologies enables mills to operate with a significantly reduced carbon footprint. These transformative methods reflect a growing recognition of the need to balance productivity with sustainability. By investing in these evolving techniques, paddy processing units are not just enhancing quality but also setting new standards for responsible agricultural practices.

Economic Impacts of Local Paddy Processing Units on Rural Communities

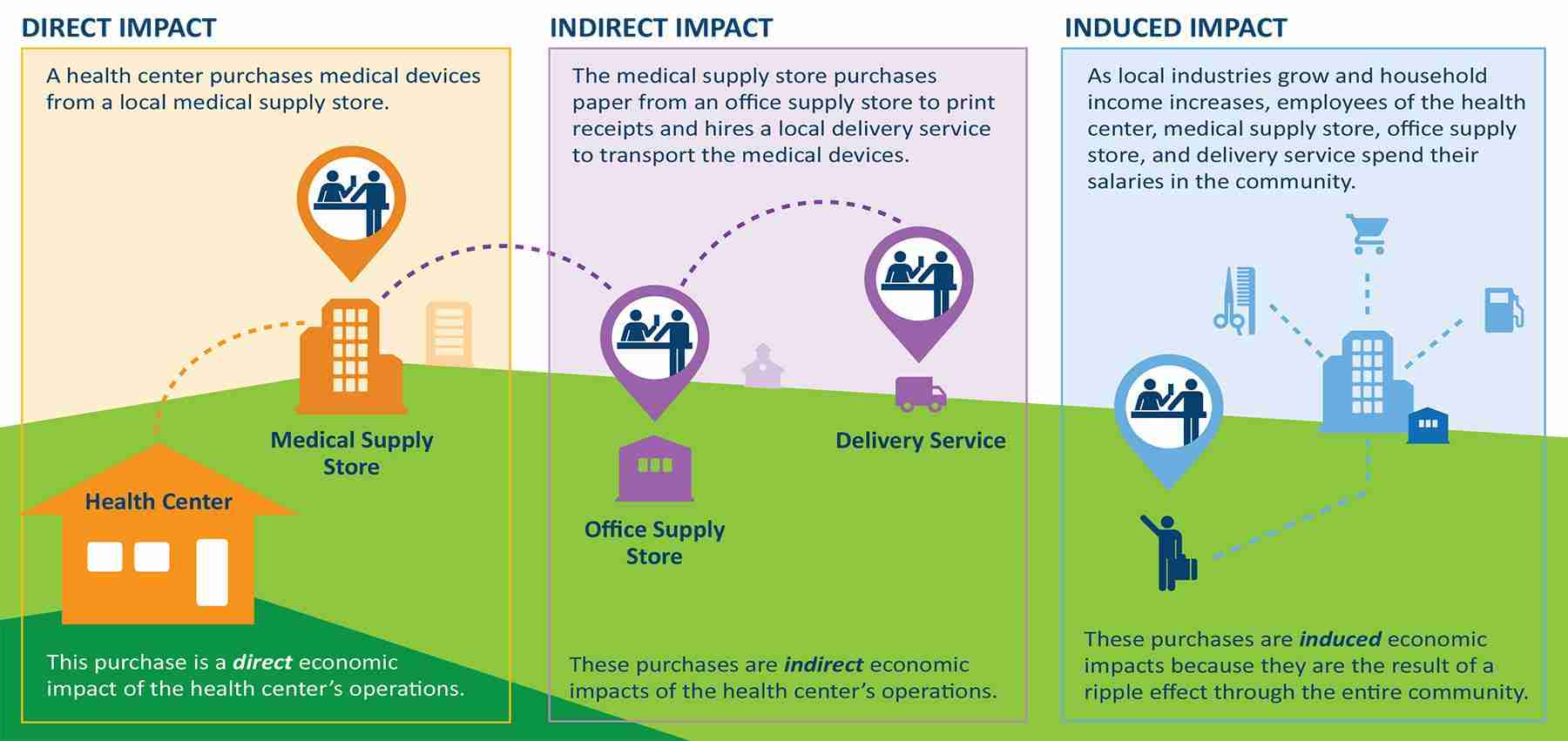

The establishment of local paddy processing units has catalyzed a significant transformation in rural economies. These units not only enhance the value of raw paddy but also create a ripple effect that boosts various ancillary businesses and local livelihoods. With the introduction of processing facilities, farmers have better access to their produce, often experiencing a substantial increase in income. Key benefits observed include:

- Job Creation: Processing units supply new employment opportunities for local residents, from labor-intensive processing jobs to technical and managerial roles.

- Value Addition: Integrated processing allows farmers to sell their paddy at a higher price after milling, leading to improved household incomes.

- Enhanced Community Stability: Increased income levels contribute to better education, healthcare, and infrastructure, fostering overall community resilience.

Moreover, the impacts extend beyond individual households to encompass broader community dynamics. With local paddy processing, there are improvements in market access and trade opportunities, fundamentally reshaping the economic landscape. Farmers can participate in collective marketing strategies, enhancing their bargaining power. The revenue generated can fuel local investments in education and health, further strengthening the community fabric. Consider the following table showcasing the economic benefits of local paddy processing:

| Economic Aspect | Before Processing Units | After Processing Units |

|---|---|---|

| Average Income per Farmer | $500/year | $800/year |

| Employment Rate | 65% | 85% |

| Investment in Local Businesses | Low | Enhanced |

Innovative Technology Adoption in Grain Transformation Processes

The landscape of grain transformation is being reshaped by cutting-edge technologies that enhance efficiency and sustainability. Paddy processing units are increasingly leveraging automation, data analytics, and environmental monitoring systems to revolutionize traditional methods. Automated milling processes, equipped with sensors and smart controls, not only optimize the rice polishing procedure but also minimize waste and energy consumption. As these units integrate advanced software for real-time data analysis, managers can make informed decisions that lead to increased yield and product quality.

Furthermore, the adoption of renewable energy solutions, such as solar panels and biogas generators, plays a pivotal role in making these processing units more sustainable. Incorporating innovative practices is not merely about modernization; it reflects a commitment to reducing the carbon footprint and enhancing the economic viability of paddy processing. Areas of focus in innovative technology integration include:

- Precision Agriculture: Utilizing drones and IoT devices to monitor crop health and soil conditions.

- Smart Storage Solutions: Implementing automated systems for better inventory management and reduced spoilage.

- Blockchain Technology: Enhancing traceability and transparency in the supply chain.

| Technology | Benefit |

|---|---|

| Automation | Reduced labor costs and increased efficiency |

| Data Analytics | Enhanced decision-making and yield optimization |

| Renewable Energy | Lower operational costs and environmental impact |

Sustainable Practices in Paddy Processing: A Pathway to Environmental Stewardship

In the quest for sustainable agriculture, paddy processing units are increasingly embracing innovative practices that minimize environmental impact while maximizing efficiency. These units have become crucial players in the movement towards eco-friendliness by adopting methods that reduce waste and conserve resources. For instance, the implementation of water recycling systems allows for the reuse of water used in milling, significantly reducing overall water consumption. Similarly, many processing units are transitioning to renewable energy sources such as solar or biomass, which not only diminish reliance on fossil fuels but also help cut operational costs in the long run.

Furthermore, sustainable waste management practices are gaining traction within the industry. By converting by-products like husk and bran into organic fertilizers, paddy mills can contribute to soil health while reducing landfill reliance. Other initiatives include the employment of advanced technologies that optimize energy use and minimize emissions. The integration of these eco-friendly approaches not only fosters a circular economy but also enhances the marketability of rice, as consumers are increasingly drawn to products that demonstrate a commitment to environmental stewardship. The combination of these initiatives sets the stage for a more sustainable future in paddy processing, ensuring that the balance between productivity and ecology is maintained.

| Sustainable Practice | Benefit |

|---|---|

| Water Recycling Systems | Reduced water consumption |

| Renewable Energy Sources | Lower carbon footprint |

| Waste-to-Fertilizer Conversion | Improved soil health |

| Energy Optimization Technologies | Less energy consumption |

The Conclusion

the journey of grain from field to table is a complex tapestry woven with the threads of innovation, tradition, and vital processing. Paddy processing units stand at the forefront of this transformation, playing an indispensable role in enhancing productivity, ensuring quality, and meeting the ever-evolving demands of consumers. As we reflect on the pivotal contributions of these processing units, it becomes clear that they are not merely facilities but rather the engines driving sustainable agricultural practices and food security. As we forge ahead into a future marked by technological advancements and shifting paradigms in food production, it remains essential to recognize and support the backbone of our grain supply chain. The story of grain is a story of progress, and with each step in the processing journey, we take another stride toward a more resilient and nourished world.