In the heart of agricultural landscapes, where golden fields of rice sway gently in the breeze, the journey from crop to cuisine is both intricate and essential. At the forefront of this undertaking lies the rice mill—a pivotal player in transforming harvested grain into the staple beloved by millions around the world. As we delve into the mechanics of the 5-ton rice mill, we will explore its efficiency and myriad benefits. This article unveils not only the technical prowess that makes this unit a cornerstone in rice processing but also its profound impact on productivity, economic viability, and sustainable farming practices. Through this exploration, we aim to shed light on how modern milling technology is reshaping an age-old industry, enhancing livelihoods, and ensuring that the humble grain can continue to nourish generations to come. Join us as we embark on this journey into the realm of rice milling, where tradition meets innovation.

Understanding the Mechanics of a 5 Ton Rice Mill

The functioning of a 5-ton rice mill is a remarkable blend of engineering and efficiency, transforming raw paddy into polished rice ready for the consumer market. At its core, this mechanical marvel operates through a series of interlinked components designed to maximize production while minimizing waste. The initial step involves the paddy feed, where the rice husk is removed through hulling machines. Following this, the milling process breaks down the grains further, achieving varying degrees of rice cleanliness and quality. Equipped with advanced features such as automatic control panels and sensors, these mills ensure constant monitoring of the process, optimizing the outcome and enhancing operational precision.

A key aspect of these mills is their energy-efficient design, which not only reduces operational costs but also minimizes the environmental impact. The multi-stage milling system allows for the separation of broken rice, husks, and other byproducts, resulting in higher yields and less wastage. Incorporating airflow systems helps in effectively using steam, which aids in the cooking of the rice during processing. The following table summarizes some essential features of a 5-ton rice mill:

| Feature | Description |

|---|---|

| Production Capacity | 5 tons of rice per hour |

| Energy Source | Electricity with energy-saving technology |

| Milling Process | Multi-stage with husk removal and polishing |

| Operation | Automated with smart sensors |

This combination of technology and innovation facilitates a streamlined operation, enabling rice producers to meet the demands of a competitive market efficiently.

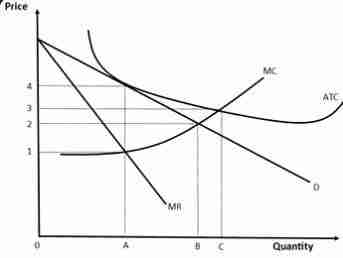

Evaluating Cost Efficiency and Productivity Gains

When analyzing the value of a 5-ton rice mill, two pivotal aspects emerge: cost efficiency and productivity gains. Investing in such a mill not only streamlines operations but also significantly reduces overall production costs. A well-designed rice mill can lead to lower energy consumption and maintenance expenses, which contribute to a more favorable return on investment. The following factors underline the cost benefits:

- Reduced Labor Costs: Automation in rice milling diminishes the need for extensive manual labor, thereby lowering payroll expenses.

- Optimized Resource Usage: A rice mill with efficient design maximizes output while minimizing waste of raw materials.

- Energy Efficiency: Modern technology ensures that energy consumption for processing is kept to a minimum.

Moreover, productivity gains derived from operating a 5-ton rice mill are noteworthy. Mill owners can expect higher throughput and improved processing times. This allows for meeting market demands with greater agility while simultaneously ensuring consistent product quality. Consider the following metrics that illustrate the potential productivity enhancements:

| Parameter | Before 5 Ton Rice Mill | After Implementation |

|---|---|---|

| Daily Processing Capacity (tons) | 2 | 5 |

| Average Processing Time (hours) | 8 | 3 |

| Labor Required (workers) | 10 | 4 |

These improvements not only underscore the economic benefits but also signify a transformative leap in operational capabilities, allowing businesses to thrive in a competitive market. By focusing on efficient processes, rice mills can produce high-quality products while maintaining a keen eye on their budget and overall productivity.

Maximizing Output: Best Practices for Operation and Maintenance

Regular maintenance is crucial in ensuring that your 5-ton rice mill operates efficiently. Implementing a rigorous maintenance schedule not only prolongs the lifespan of the machinery but also enhances its performance. Key practices include:

- Daily Inspections: Check for unusual noises or vibrations, which can indicate mechanical issues.

- Lubrication: Ensure that all moving parts are properly lubricated to minimize wear and prevent breakdowns.

- Cleaning: Regularly clean the mill to remove residues that can clog components and lead to inefficiencies.

- Calibration: Periodically calibrate machines to maintain production accuracy and quality control.

Additionally, training personnel on best operational practices is vital. Well-informed operators can maximize output by understanding the machinery’s technology and workflows. Consider the following strategies to enhance operational efficiency:

- Load Optimization: Ensure the mill runs at optimal capacity without overloading, which can lead to mechanical failures.

- Data Monitoring: Utilize data tracking to gauge productivity metrics and identify bottlenecks in the milling process.

- Feedback Loops: Establish channels for operators to report issues and suggestions for continuous improvements.

- Scheduled Downtime: Plan for regular downtime to conduct preventive maintenance without disrupting production schedules.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Daily | Check for obvious issues |

| Lubrication | Weekly | Use recommended lubricants |

| Deep Cleaning | Monthly | Focus on moving parts and specifications |

| Performance Review | Quarterly | Assess efficiency metrics |

Exploring Environmental Benefits and Sustainable Practices

The implementation of a 5-ton rice mill is not just a leap towards better efficiency in production but also a step towards sustainable agricultural practices. By utilizing advanced milling technology, this equipment minimizes waste and optimizes the use of natural resources. Key environmental benefits include:

- Reduction in Energy Consumption: Modern mills are designed to be energy-efficient, lowering the overall carbon footprint associated with rice processing.

- Smart Water Management: These mills integrate systems that recycle water used in processing, thus conserving this vital resource.

- Lower Emission Levels: By substituting traditional methods with advanced machinery, emissions are significantly reduced, promoting cleaner air.

Moreover, sustainable practices fostered by a 5-ton rice mill can contribute to local economies while ensuring environmental integrity. The adoption of eco-friendly byproducts is another notable advantage. For example, the husk produced during milling can be transformed into biofuel or used in organic fertilizers, closing the loop of waste management. A brief comparison of traditional vs. modern rice milling practices can highlight the substantial benefits:

| Practice | Traditional Milling | 5 Ton Rice Mill |

|---|---|---|

| Energy Use | High | Low |

| Water Consumption | Excessive | Optimized |

| Waste Production | High | Minimal |

| By-products Utilization | Limited | Extensive |

To Conclude

the exploration of a 5-ton rice mill reveals a compelling narrative of innovation and practicality in the realm of agriculture. By harnessing modern technology and efficient design, these mills not only optimize production but also contribute to the sustainability of rice farming. The benefits extend far beyond mere output; they touch on economic viability, resource management, and the empowerment of local communities. As we continue to navigate the complexities of food production, the 5-ton rice mill stands as a testament to the potential for growth and improvement within the agricultural sector. Embracing such advancements may not only enhance efficiency but also pave the way for a more resilient and sustainable future in rice cultivation. With each grain milled, we inch closer to a harmonious balance between tradition and innovation, strengthening the foundations of our food systems for generations to come.