Understanding Cereal Milling: The Art and Science Behind Grains

In the tapestry of human civilization, grains have served as threads that weave together cultures, sustenance, and innovation. From the dawn of agriculture to the bustling mills of today, the journey of cereal grains from field to flour is a story rich in both tradition and transformation. At the heart of this journey lies cereal milling—a meticulous process that combines ancient techniques with modern technology, unlocking the potential of nature’s bounty. This article invites you to explore the intricate world of cereal milling, shedding light on the delicate balance of art and science that shapes the grains we so often take for granted. Join us as we delve into the methods, machinery, and expertise that converge to convert raw grain into essential staples, revealing the hidden complexities of a craft that nourishes millions around the globe.

Exploring the Anatomy of Common Grains and Their Milling Potential

The structure of grains is as intricate as it is fascinating, resembling a well-crafted piece of art. At the core of these nutrient-dense wonders are three primary components: the bran, the endosperm, and the germ. Each element contributes uniquely to the grain’s nutritional profile and milling potential. The bran, a fibrous outer layer, is rich in dietary fiber and essential nutrients, making it a valuable addition to whole grain products. The endosperm serves as the main starchy part, providing energy and acting as the final grind in milling. Nestled inside is the germ, which houses a treasure trove of vitamins, minerals, and healthy fats. Understanding these components allows millers to optimize the milling process, adjusting techniques to either preserve or extract specific parts based on the desired flour characteristics.

When considering the milling potential of common grains such as wheat, rice, and corn, it’s crucial to evaluate their anatomical differences and corresponding processing requirements. For instance, milling techniques vary significantly between hard and soft wheat varieties, each yielding distinct flour types suitable for various culinary creations. The following table highlights key differences in milling yields and potential applications:

| Grain Type | Milling Yield | Common Uses |

|---|---|---|

| Hard Wheat | 75-80% | Breads, Pasta |

| Soft Wheat | 70-75% | Baked Goods, Pastries |

| Rice | 68-72% | Rice Flour, Sushi |

| Corn | 70-75% | Polenta, Tortillas |

Such knowledge not only amplifies the efficiency of the milling process but also enhances the quality and flavor profile of the final products. As millers delve deeper into the anatomy of grains, they unveil a world of possibilities that cater not only to culinary delights but also to advancing nutritional standards in our diets.

The Milling Process Demystified: From Whole Grain to Flour

The journey of grain from farm to flour is a fascinating blend of art and science, intricately woven through each step of the milling process. At the outset, whole grains, bursting with nutrients, are carefully selected based on variety and quality. The grains then undergo a thorough cleaning to remove any impurities, ensuring that only the purest grains make it into the milling machinery. Once cleaned, the grains are tempered, a process that involves adding moisture to enhance their milling properties. This transformation readies the grains, allowing the milling machinery to effectively break them down into a fine powder.

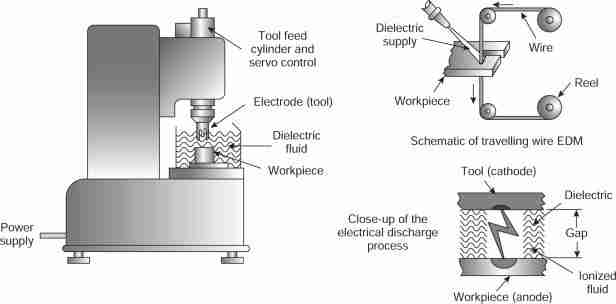

The actual milling process employs a series of steps designed to extract the desired flour consistency while preserving essential nutrients. Typically, the milling is divided into two primary methods: stone milling and roller milling. Stone milling involves the use of large stones to crush the grains, producing flour that retains more of the grain’s natural flavor and nutritional value. Roller milling, on the other hand, utilizes a series of rollers to pulverize the grains, allowing for a more refined flour with a longer shelf life. The resulting flour is then sifted and sometimes blended to achieve the desired texture, color, and baking characteristics.

| Method | Description | Benefits |

|---|---|---|

| Stone Milling | Crushing grains with large stones |

|

| Roller Milling | Grinding grains with a series of steel rollers |

|

Techniques and Technologies: Innovations Shaping the Future of Cereal Milling

Cereal milling has undergone a remarkable transformation thanks to advancements in technology that enhance both efficiency and quality. One of the most notable innovations is automated milling systems, which utilize sophisticated algorithms and sensors to monitor the milling process in real-time. This ensures optimal grain extraction and minimizes waste. Additionally, artificial intelligence (AI) is being harnessed to predict equipment failures and optimize maintenance schedules, thus increasing the reliability of milling operations. The integration of data analytics allows millers to analyze historical performance metrics, significantly improving decision-making processes.

Moreover, emerging sustainable practices are reshaping the landscape of cereal milling. Eco-friendly milling technologies are gaining traction, aiming to reduce energy consumption and carbon footprint. For example, the development of bio-based lubricants in machinery is contributing to a cleaner production environment. The trend toward modular milling systems also facilitates scalability, allowing millers to adjust capacity according to demand seamlessly. Below is a table showcasing some innovative technologies currently influencing the cereal milling industry:

| Technology | Benefits |

|---|---|

| Automated Milling Systems | Real-time monitoring and reduced waste |

| Artificial Intelligence | Predictive maintenance and improved reliability |

| Eco-Friendly Technologies | Lower energy usage and sustainable practices |

| Modular Milling Systems | Easily adjustable milling capacity |

Nutritional Aspects of Milled Grains: Enhancing Health through Proper Processing

The transformation of whole grains into milled products is not merely a culinary endeavor; it is a meticulous process that has significant implications for our nutritional intake. Through the methodical removal of the bran and germ, milling not only extends the shelf life of grains but also alters their nutrient profile. While this process increases convenience, it may inadvertently reduce the levels of essential vitamins and minerals typically found in the outer layers of the grain. Nonetheless, advancements in milling technology and fortification practices have made it possible to retain and even enhance the nutritional value of milled grains.

To maximize the health benefits of milled grains, it is crucial to select products that are intentionally enriched or minimally processed. Choosing whole grain options can provide superior nutrition, offering a wealth of health benefits, including:

- Increased Fiber Content: Essential for digestive health.

- Greater Antioxidant Activity: Helps combat oxidative stress.

- Enhanced Micronutrient Availability: Key vitamins and minerals support overall wellness.

Here’s a brief comparison of the nutritional profiles of whole grains versus milled grains:

| Property | Whole Grains | Milled Grains |

|---|---|---|

| Fiber (per 100g) | 7g | 2g |

| Vitamin B6 | 0.1mg | 0.05mg |

| Iron | 3.5mg | 1mg |

By prioritizing whole grains in our diets while also being mindful of enrichment and processing techniques, we can harness the full spectrum of health benefits that grains have to offer. Understanding the differences in nutrient profiles empowers consumers to make informed choices, reinforcing the essential role of grains in a balanced diet.

The Conclusion

As we come to the end of our exploration into the intricate world of cereal milling, it becomes evident that this process is much more than a simple grinding of grains. It is a harmonious blend of art and science, where tradition meets innovation, and where the humble grain transforms into the cornerstone of our diets. From the careful selection of seeds to the precise calibration of milling machinery, every step is a testament to both age-old techniques and modern advancements.

Understanding cereal milling not only sheds light on how our food is produced but also highlights the remarkable journey that grains undertake from field to table. As we savor our morning bowls, let us appreciate the craftsmanship and expertise that go into every flake and grain. Armed with this knowledge, we can make informed choices about the foods we consume, fostering a deeper connection to the land and the processes that nourish us.

In this ever-evolving landscape of grain milling, one thing remains clear: the future of our food is as rich and diverse as the grains themselves. Whether you are a farmer, miller, or simply a curious reader, may this understanding inspire you to delve deeper into the flourishing world of grains and the artistry that brings them to life.