In the hustle and bustle of our daily routines, we often overlook the humble breakfast cereal that kickstarts our mornings. But have you ever stopped to wonder about the fascinating process that turns grains into the beloved breakfast staple? Join us as we take a deep dive into the world of cereal processing, uncovering the intricate steps that go into creating those crispy, crunchy flakes we know and love. From farm to bowl, let’s break down breakfast and explore the journey of cereal before it reaches our tables.

Exploring the Various Steps of Cereal Processing

Have you ever wondered how your favorite breakfast cereals are made? The process of cereal processing is a complex series of steps that transform raw grains into the crunchy, flavorful breakfast staple we all know and love. Let’s take a closer look at the various stages that go into creating the perfect bowl of cereal.

- Cleaning and Sorting: The first step in cereal processing involves cleaning and sorting the raw grains to remove any impurities such as dirt, rocks, or other foreign materials. This ensures that only the highest quality grains are used in the production of cereal.

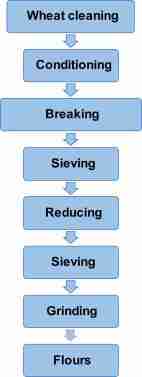

- Milling: Once the grains have been cleaned and sorted, they are milled to remove the outer husk and bran layers. This process helps to extract the starchy inner portion of the grain, which is then ground into flour to create the base ingredient for the cereal.

- Blending: After milling, the flour is blended with other ingredients such as sugar, salt, vitamins, and flavorings to create the unique taste and texture of each type of cereal.

Next, the blended ingredients are cooked and shaped into the familiar flakes, loops, or puffs that make up different varieties of cereal. These shapes are then dried to remove excess moisture and ensure a long shelf life. Finally, the cereal is packaged and distributed to stores around the world, ready to be enjoyed by cereal lovers of all ages.

| Cereal Processing Steps: |

|---|

| Cleaning and Sorting |

| Milling |

| Blending |

| Cooking and Shaping |

| Drying |

| Packaging |

Now that you know more about the fascinating process of cereal processing, you can appreciate the amount of time and effort that goes into creating the breakfast foods we all enjoy each day. So, next time you pour yourself a bowl of cereal, take a moment to savor not just the taste, but the journey it took to get there.

From Farm to Table: Tracing the Journey of Cereal Grains

When you pour a bowl of cereal in the morning, do you ever stop to think about the journey those grains took to get to your table? Let’s take a closer look at the fascinating process of cereal processing, from farm to breakfast bowl.

First, cereal grains are harvested from fields on farms across the country. These grains, such as wheat, corn, and oats, are then transported to processing plants where they undergo a series of steps to transform them into the cereals we know and love. The grains are cleaned, sorted, and milled to remove any impurities and create the perfect texture for breakfast. Next, they may be fortified with vitamins and minerals before being shaped into the familiar flakes, loops, or squares that make up your favorite cereals. Finally, the finished products are packaged and shipped to grocery stores, ready to be enjoyed by families everywhere.

Unveiling the Secrets Behind Cereal Production

Have you ever wondered how your favorite breakfast cereals are made? Dive into the fascinating world of cereal production with us as we uncover the secrets behind the process. From the farm to your bowl, there are many steps involved in creating those crunchy, flavorful flakes that start your day off right.

First, the raw ingredients are sourced from farmers who specialize in growing grains like wheat, corn, or oats. These grains are then cleaned, milled, and cooked to create the base for the cereal. Next, flavors, colors, and sweeteners are added to enhance the taste and appearance. The mixture is then shaped into the familiar shapes we all know and love, like loops, squares, or flakes. Finally, the cereal is toasted to achieve that perfect crunch before being packaged and sent off to your local grocery store. Now that you know the process, you can enjoy your cereal with a newfound appreciation for the craftsmanship behind each bite.

Maximizing Nutrition and Flavor in Your Breakfast Cereal

When it comes to , understanding the process behind cereal processing is key. From the selection of quality grains to the way they are processed and packaged, each step plays a crucial role in the final product that ends up in your bowl.

One important aspect of cereal processing is the way grains are milled. **Whole grains** are often preferred for their higher nutrient content, but the milling process can impact both the texture and flavor of the final product. Whether grains are cracked, rolled, or ground into flour, each method can yield a different result in terms of taste and texture. Additionally, the addition of **nutritious ingredients** such as nuts, seeds, and dried fruit can further enhance the nutritional value and flavor profile of your breakfast cereal.

The Way Forward

As we have delved into the fascinating world of cereal processing, we have gained a deeper appreciation for the intricate and innovative techniques used to create our favorite breakfast foods. From the farm to your bowl, every step in the process plays a crucial role in delivering the crispy, flavorful cereals we enjoy each morning. So, the next time you pour yourself a bowl of cereal, take a moment to savor the complexity of its journey from grain to breakfast table. And remember, breakfast truly is the most important meal of the day!