Step into the world of rice milling, where the ancient art of transforming raw grains into the beloved staple food takes center stage. In this article, we will delve into the intricate process of rice milling, unraveling the hidden complexities and skills involved in producing the pristine white rice that graces our tables. Join us on a journey through the heart of this time-honored tradition, as we uncover the artistry and precision that go into each grain of rice.

Understanding the Essential Steps in Rice Milling

Rice milling is a fascinating process that involves several essential steps to transform raw rice grains into the polished, white rice we commonly see on our tables. One of the first steps in rice milling is cleaning the rice to remove any impurities such as dust, stones, or debris. This ensures that the final product is of high quality and safe for consumption. Once the rice is clean, it is then soaked in water to soften the grains and make it easier to remove the outer husk. This soaking process also helps to improve the texture and taste of the rice.

After soaking, the rice is passed through a milling machine that removes the outer husk, bran layer, and germ from the grain, leaving behind the white rice kernel. The final step in the rice milling process is polishing the rice to give it a shiny appearance and improve its overall quality. This involves removing any remaining bran or germ particles on the surface of the rice. The result is a batch of perfectly polished, white rice ready to be packaged and sold to consumers around the world.

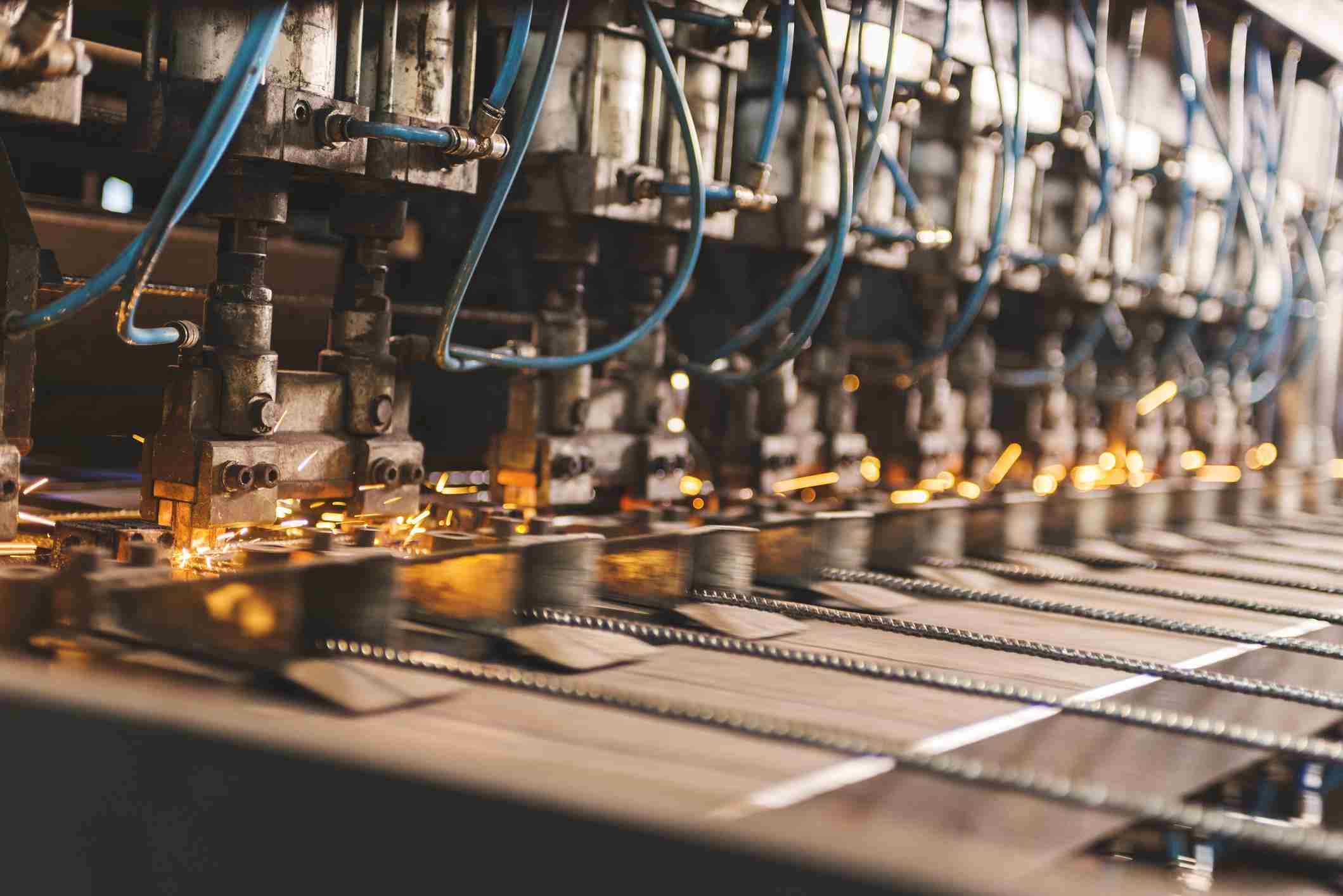

Exploring the Machinery and Technology Used in Modern Rice Mills

Rice milling is a complex and intricate process that involves a series of machinery and technology to transform raw rice grains into the polished white rice we see on our plates. One key component of modern rice mills is the paddy separator, which helps to separate the husks and bran from the rice kernels. This process is crucial in producing high-quality rice that is free from impurities.

Another important piece of equipment in rice mills is the rice whitener, which removes the remaining bran layers from the rice kernels to reveal the shiny white appearance that we are familiar with. Additionally, color sorters play a vital role in ensuring that the rice grains are uniform in color and free from any defects. These technological advancements have revolutionized the rice milling industry, making the process more efficient and precise than ever before.

Tips for Improving Efficiency and Quality in Rice Milling Operations

Rice milling is a delicate process that requires precision and care to ensure the efficiency and quality of the final product. One key tip for improving efficiency in rice milling operations is to regularly maintain and clean the machinery used in the process. This helps prevent clogging and ensures smooth operation, resulting in a higher output of quality rice.

Another important factor to consider is the moisture content of the rice grains. Properly drying the rice before milling is crucial for achieving a consistent and high-quality end product. Additionally, investing in modern technology such as automated sorting machines can help streamline the sorting process and improve the overall efficiency of the milling operation.

The Future of Rice Milling: Trends and Innovations to Watch Out For

As technology continues to advance, the future of rice milling is rapidly evolving with new trends and innovations on the horizon. One of the key trends to watch out for is the rise of automation in rice milling processes. Automation allows for greater efficiency and precision in the milling process, resulting in higher quality rice products. Additionally, advancements in machine learning and artificial intelligence are being integrated into rice milling equipment to optimize performance and reduce waste.

Another innovation to keep an eye on is the development of sustainable rice milling practices. With growing concerns about environmental impact, rice millers are looking for ways to minimize energy consumption and reduce water usage in the milling process. New technologies such as water-saving milling techniques and energy-efficient equipment are being introduced to help rice mills operate more sustainably.

The Conclusion

As we conclude our exploration into the intricate world of rice milling, it becomes evident that this age-old process holds both practicality and artistry in its grains. From the meticulous sorting and cleaning to the precise polishing and packaging, each step in the journey from paddy to rice is a testament to human ingenuity and dedication. Next time you enjoy a steaming bowl of perfectly cooked rice, take a moment to appreciate the silent craftsmanship that brought it to your table. The art of rice milling is truly a marvel to behold, bridging tradition and innovation in the most humble of grains.