In the quiet hum of a bustling cereal mill, the marriage of art and science comes to life. From the precise measurements of grains to the rhythmic dance of ancient milling machinery, the process of turning grains into the breakfast staple we know as cereal is an intricate blend of craftsmanship and chemistry. Join us on a journey into the world of cereal milling, where tradition meets innovation to create the perfect bowl of flakes or puffs.

Understanding the Importance of Particle Size in Cereal Milling

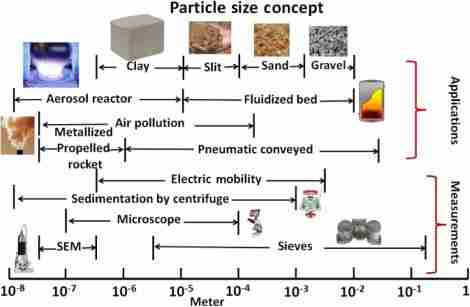

When it comes to cereal milling, one of the key factors that can greatly impact the quality of the final product is particle size. The size of the particles in milled cereals plays a crucial role in determining aspects such as texture, flavor, and shelf life. is essential for achieving the desired characteristics in the end product.

Proper control of particle size in cereal milling requires a combination of art and science. By carefully adjusting the milling process, it is possible to achieve the ideal particle size distribution for a specific type of cereal. This precision not only ensures consistent quality across batches but also allows for customization according to consumer preferences. With the right balance of expertise and technology, cereal milling can truly become both an art and a science.

Key Factors Influencing Flour Quality in Milling Processes

The quality of flour in milling processes is influenced by a myriad of key factors that require both art and science to navigate successfully. One crucial factor is the type of cereal being milled, with each variety posing unique challenges and opportunities for achieving optimal flour quality. Understanding the characteristics of different grains, such as wheat, corn, or rice, is essential for determining the appropriate milling techniques and settings.

Another vital consideration is the milling equipment and process used, as the efficiency and precision of the machinery can significantly impact the final product. Factors such as moisture content, milling speed, and sieving methods play a crucial role in determining the particle size distribution, gluten development, and overall flour quality. By carefully balancing these key factors and continuously monitoring the milling process, millers can achieve consistent and high-quality flour that meets the requirements of various end products.

Optimizing Milling Techniques for Maximum Efficiency and Product Quality

When it comes to cereal milling, achieving maximum efficiency and product quality is truly an art form. The process involves a delicate balance of various techniques and factors that can greatly impact the final output. By optimizing milling techniques, you can ensure that you are getting the most out of your grain and producing high-quality products that meet consumer expectations.

- Utilize the latest technology and equipment to streamline the milling process.

- Regularly monitor and adjust settings to maintain consistency and quality in the final product.

- Implement proper cleaning and maintenance routines to prevent contamination and ensure product safety.

It is important to remember that cereal milling is not just a science, but also an art. By combining technical expertise with creativity and innovation, you can push the boundaries of what is possible in the world of milling. With the right approach, you can unlock new levels of efficiency and product quality that will set you apart from the competition.

The Role of Technology and Innovation in Modern Cereal Milling Operations

Technology and innovation have revolutionized the way cereal milling operations are carried out in modern times. With the advancement of machinery and equipment, the process of turning grains into flour has become more efficient and precise. Automated systems now handle tasks that were once done manually, resulting in higher productivity and better quality products.

One of the key technologies that have transformed cereal milling is the use of computerized systems to control the entire process. These systems monitor factors such as temperature, humidity, and grain size, ensuring that each batch of flour is consistent and meets the desired specifications. In addition, innovations in milling techniques, such as the use of air classification and roller milling, have led to improved end products that are not only finer but also have a longer shelf life. The combination of art and science in modern cereal milling operations has enabled producers to meet the demands of a growing market while maintaining high standards of quality and efficiency.

The Conclusion

As we have delved into the fascinating world of cereal milling, we have uncovered the intricate balance of art and science that goes into producing that perfect bowl of cereal. From the precision of the process to the creativity in crafting unique blends, cereal milling truly is a marvel to behold. As we savour each spoonful of our morning breakfast, let us take a moment to appreciate the craftsmanship and expertise that goes into every crunch. Here’s to the endless possibilities that arise when art and science come together in the form of a humble bowl of cereal.