Rice is a staple food for billions of people around the world, making efficient rice production crucial for global food security. In order to meet the growing demand for rice, farmers and millers are constantly seeking innovative solutions to improve their production processes. One such solution is the development of a highly efficient 4 ton rice mill plant, designed to streamline operations and maximize output. This article explores the benefits of this cutting-edge technology and how it is revolutionizing the rice milling industry.

Overview of 4 Ton rice mill plant Components

When it comes to maximizing rice production, having an efficient 4 ton rice mill plant is crucial. This plant is equipped with various components that work together seamlessly to ensure a smooth and productive milling process.

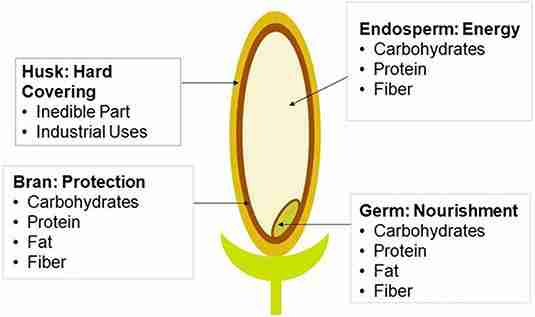

- Paddy Separator: This component helps to separate the husk from the rice, ensuring that only the pure grains are processed further.

- Rice Polishing Machine: The rice polishing machine gives the rice its shiny appearance by removing the bran layer, resulting in a more appealing final product.

- Bucket Elevator: The bucket elevator is responsible for transporting the rice from one machine to another, reducing manual handling and increasing efficiency.

Key Features for Enhanced Efficiency in Production

Experience the power of our efficient 4 ton rice mill plant, designed to revolutionize your production process. With state-of-the-art features focused on enhancing efficiency, this plant is guaranteed to improve your output and streamline your operations.

Key features of this innovative plant include automated grain feeding system for continuous processing, high-speed milling unit for rapid production, precision sorting mechanism for superior quality control, and integrated dust collection system for a clean working environment. Invest in this plant today and take your production to the next level.

Best Practices for Maintaining and Operating the rice mill plant

When it comes to maintaining and operating a rice mill plant, there are several best practices that can help ensure efficient production and improved output. One important aspect is regular maintenance of machinery to prevent breakdowns and ensure smooth operations. Conducting routine checks on all equipment and machinery can help identify any potential issues early on and address them before they escalate.

Another key factor in maintaining a rice mill plant is proper training for staff members. Ensuring that all operators are well-trained in operating the machinery can help minimize errors and improve overall efficiency. Additionally, implementing quality control measures throughout the production process can help maintain the high standards of the final product. By following these best practices, you can optimize the performance of your 4 ton rice mill plant and achieve increased production levels.

Maximizing Output Through Upgrades and Modernization

Looking to maximize your rice mill plant’s output? Consider upgrading to a new and efficient 4-ton rice mill plant for improved production. With advancements in technology and modernization, investing in a high-capacity mill can significantly boost your processing capabilities and enhance overall efficiency. By incorporating the latest features and upgrades, you can streamline operations, increase throughput, and ultimately achieve higher yields.

When upgrading to a 4-ton rice mill plant, you can benefit from innovative design elements such as:

- Automated controls for enhanced precision and consistency in processing

- Improved grain separation mechanisms for higher quality output

- Energy-efficient components to reduce operating costs

| Feature | Benefit |

|---|---|

| Automated Controls | Enhanced precision and consistency |

| Improved Grain Separation | Higher quality output |

| Energy-efficient Components | Reduced operating costs |

Closing Remarks

In conclusion, investing in an efficient 4 ton rice mill plant can significantly improve production and streamline operations for rice farmers and millers alike. With advanced technology and automation, this plant offers a promising solution for maximizing output while minimizing labor and energy costs. By embracing this innovative approach, the future of rice production looks brighter than ever. Upgrade your mill today and reap the benefits of increased efficiency and improved production. Happy milling!