Enter the fascinating world of cereal milling, where grains are transformed through the age-old process of grinding. Delve into the science behind this essential practice, as we explore the intricacies of turning raw grains into the breakfast staples we know and love. Join us as we uncover the art and precision of cereal milling, shedding light on the techniques and technologies that have shaped this timeless tradition.

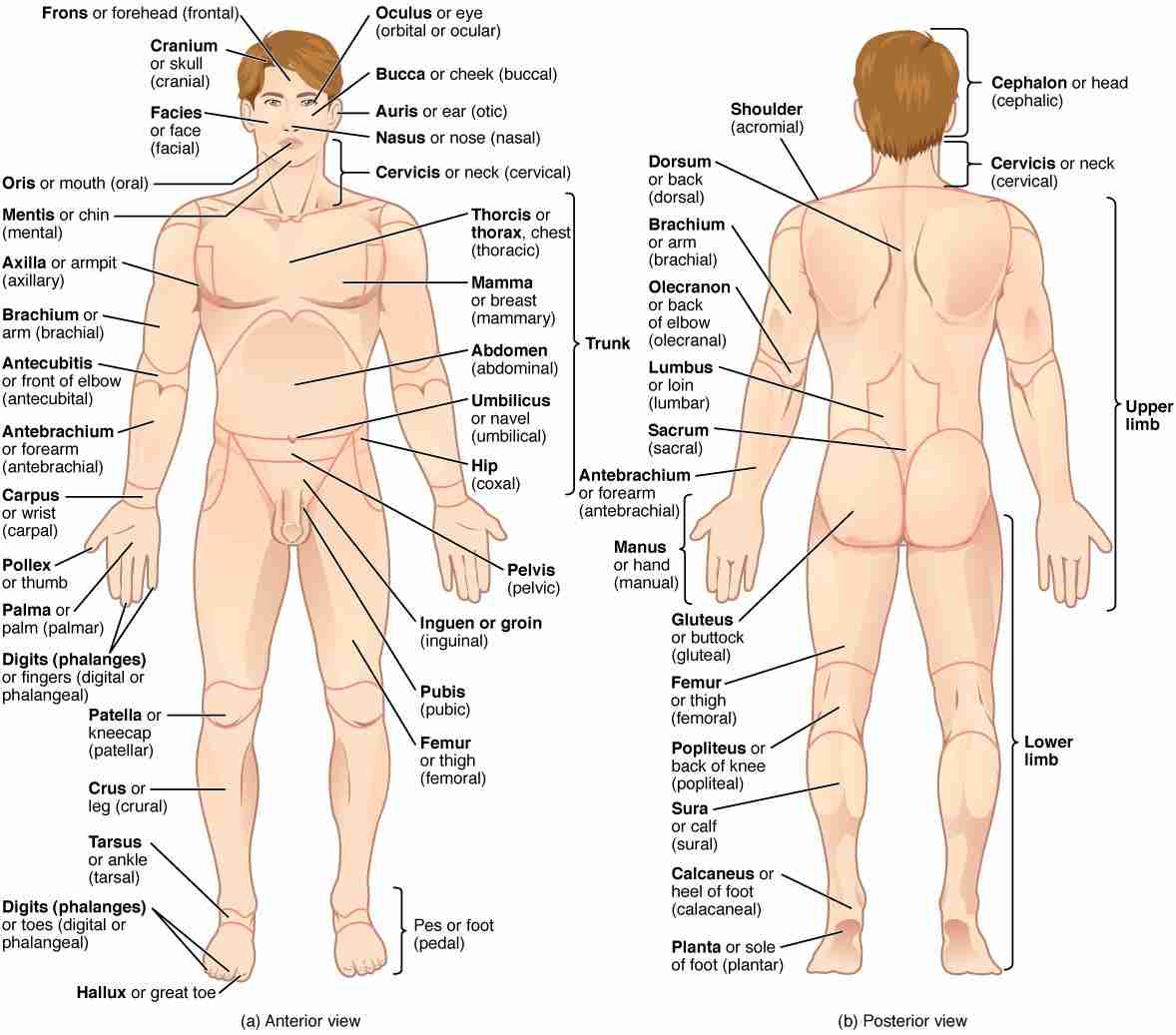

Understanding the Anatomy of Cereal Grains

Grinding grains is a fascinating process that involves the breakdown of cereal grains into fine particles to create flour for various culinary purposes. The science of cereal milling delves into the intricate anatomy of grains and how they are transformed through the milling process.

is crucial for achieving the desired texture and consistency in the final flour product. Each grain consists of different components, such as the bran, endosperm, and germ, which play a vital role in determining the quality of the flour. By carefully milling grains and preserving these components, millers can create flour with optimal nutritional value and flavor. The art of cereal milling combines precision and expertise to produce high-quality flour for baking, cooking, and other applications.

The Impact of Grind Size on Flavor and Texture

When it comes to grinding grains for cereal milling, cannot be understated. The size of the grains determines how they will interact with water, heat, and other ingredients during the milling process. A finer grind size will result in a smoother texture and more intense flavor, while a coarser grind size will provide a chunkier texture and a milder taste.

Understanding the science behind grind size is crucial for cereal manufacturers looking to create the perfect product. By experimenting with different grind sizes, they can fine-tune the flavor and texture of their cereals to meet consumer preferences. In addition to the size of the grains, factors such as moisture content, milling speed, and temperature can also affect the final product. By carefully controlling these variables, manufacturers can ensure that their cereals are not only delicious but also consistent in quality and taste.

Optimizing Milling Techniques for Maximum Nutritional Benefits

When it comes to maximizing the nutritional benefits of grains, the science of cereal milling plays a crucial role. By understanding the optimal techniques for grinding grains, we can ensure that we are getting the most out of our food in terms of both flavor and nutrition. One key aspect of milling techniques is the fineness of the grind. Finer grains allow for better absorption of nutrients during digestion, making them more beneficial for our bodies.

Another important factor to consider in cereal milling is the temperature control during the grinding process. Keeping the temperature low helps to preserve the delicate nutrients in the grains, ensuring that they retain their nutritional value. By paying attention to these key aspects of milling techniques, we can unlock the full potential of grains and enjoy all the health benefits they have to offer.

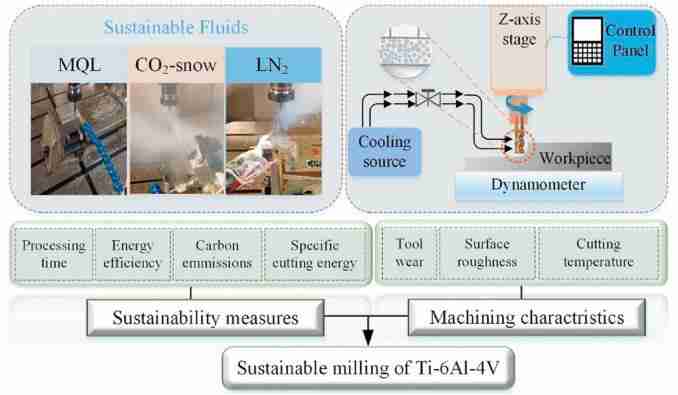

Exploring the Role of Different Mills in Grain Processing

When it comes to grain processing, the type of mill used can greatly impact the final product. Different mills have distinct mechanisms of action that can influence the texture, flavor, and nutrient content of the grains. One common type of mill is the roller mill, which utilizes a series of rollers to crush the grain. This process results in a fine and consistent grind, making roller mills ideal for producing flour for baking.

Another type of mill is the hammer mill, which uses hammers to pulverize the grain. Hammer mills are known for their ability to produce a wide range of particle sizes, making them versatile for various applications. Additionally, stone mills are also popular in grain processing, as they use natural stone to grind the grains, preserving the natural flavors and nutrients. Understanding the role of different mills in grain processing is essential for achieving the desired outcome in food production.

Insights and Conclusions

In conclusion, the process of cereal milling is a fascinating blend of art and science, where grains are transformed into the staple foods that sustain us. Through the intricate dance of grinding, sifting, and blending, millers create the perfect balance of flavor, texture, and nutrition in every batch of cereal. Whether it’s a hearty bowl of oatmeal for breakfast or a slice of crusty bread for lunch, we owe a debt of gratitude to the dedicated professionals who master the science of cereal milling. Next time you sit down to enjoy a meal made from grains, take a moment to appreciate the centuries-old tradition and innovation that goes into every bite.