In the world of breakfast favorites, cereal stands out as a beloved staple enjoyed by millions each day. But have you ever stopped to think about the intricate process behind creating those crunchy, flavorful flakes? In this article, we will delve into the art of cereal processing, unveiling the techniques and methods that bring your morning bowl to life. From harvesting the grains to toasting, shaping, and flavoring, join us on a journey through the fascinating world of cereal production.

The Importance of Proper Grain Cleaning in Cereal Processing

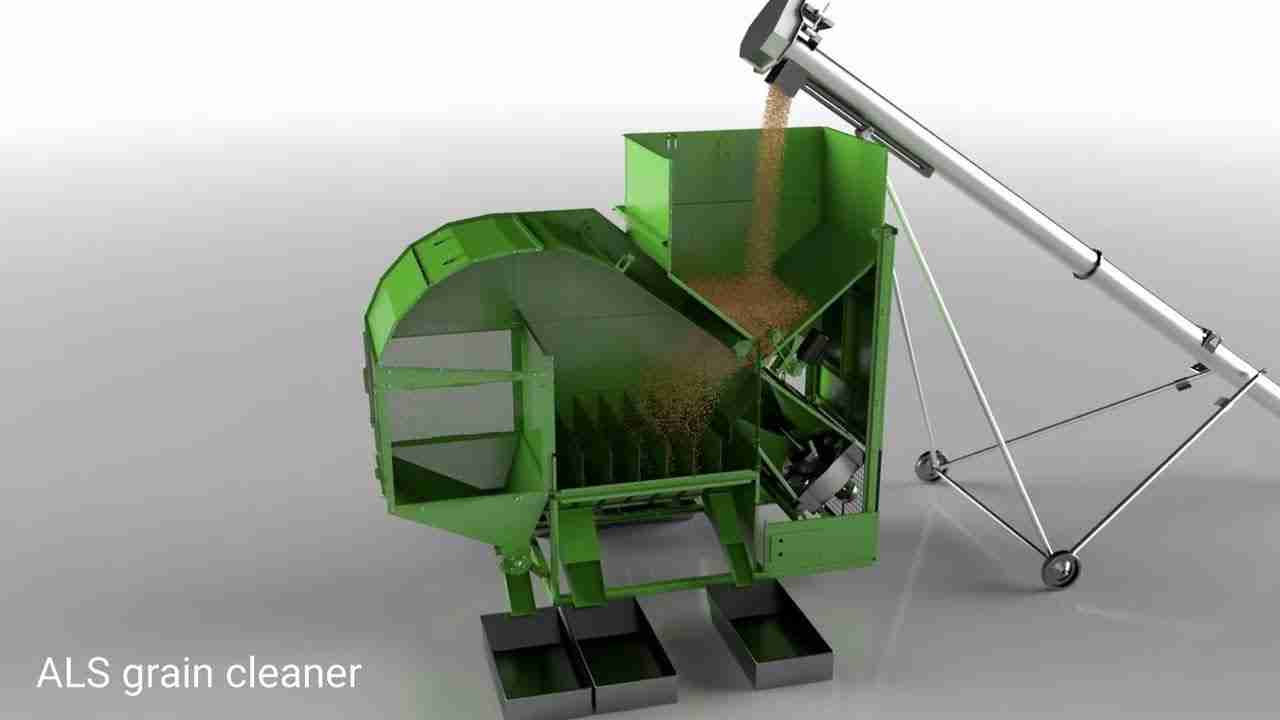

Proper grain cleaning is a crucial step in cereal processing that often goes unnoticed by the average consumer. However, this step is vital in ensuring the quality and safety of the final product. By removing impurities such as dust, debris, and foreign materials from the grains, manufacturers can prevent contamination and improve the overall taste and appearance of the cereal.

There are several techniques used in grain cleaning, including air aspiration, sieving, and magnetic separation. Air aspiration involves using airflow to remove lightweight impurities, while sieving separates grains based on size. Magnetic separation is used to remove magnetic materials from the grains. By employing these techniques in combination, manufacturers can effectively clean the grains and produce high-quality cereals for consumers to enjoy.

Exploring Various Methods of Milling for Optimal Cereal Quality

When it comes to processing cereals, there is an array of milling methods at our disposal to ensure optimal quality. Each technique has its unique advantages and can significantly impact the final product. One common method is roller milling, where grain is crushed between two rotating rollers to produce flour with a finer texture. This process is known for its efficiency in separating the bran and germ layers from the endosperm, resulting in a smoother and more uniform product.

Another method worth exploring is impact milling, which involves the use of high-speed rotating hammers to break down the grain into smaller particles. This technique is ideal for producing whole grain flours with a coarser texture and more pronounced nutty flavor. By understanding the intricacies of these milling methods, we can unlock the full potential of cereals and create products that are not only nutritious but also delicious.

Understanding the Impact of Tempering on Cereal Texture and Flavor

Tempering is a crucial step in the processing of cereals, affecting both texture and flavor in significant ways. This technique involves exposing the grains to moisture and heat, allowing them to absorb water and subsequently swell. The impact of tempering on cereals is profound, as it determines the final product’s mouthfeel, crunchiness, and overall taste.

Through proper tempering, cereal manufacturers can achieve the desired texture and flavor profiles for their products. By controlling factors such as moisture content, temperature, and duration of tempering, they can create cereals that are crispy, chewy, or a combination of both. Understanding the science behind tempering is essential for producing high-quality cereals that are both delicious and satisfying to consume.

Enhancing Cereal Nutrition Through Enrichment and Fortification

Cereal processing techniques play a crucial role in enhancing the nutritional value of our favorite breakfast staple. Through the art of enrichment and fortification, cereal manufacturers are able to provide consumers with a product that is not only delicious but also packed with essential vitamins and minerals. By carefully selecting and incorporating key nutrients into the production process, cereals are transformed into a powerhouse of nutrition.

One way cereal nutrition can be enhanced is through the addition of vitamins such as vitamin D and vitamin B12. These vitamins are crucial for overall health and well-being, and by fortifying cereals with them, manufacturers are able to offer consumers a convenient way to ensure they are meeting their daily intake requirements. In addition to vitamins, minerals such as iron and zinc can also be added during processing to further boost the nutritional profile of cereals. By understanding the science behind enrichment and fortification, we can truly appreciate the art of cereal processing.

In Conclusion

In conclusion, the art of cereal processing is a fascinating blend of science, technology, and creativity. By delving into the various techniques used in the production of our favorite breakfast staple, we gain a greater appreciation for the skill and precision required to bring those beloved crunchy bites to our bowls every morning. So next time you pour yourself a bowl of cereal, take a moment to savor not just the flavors, but also the artistry that went into making it. Here’s to the humble cereal grain and the magic that transforms it into a beloved breakfast treat.