Corn, also known as maize, has been a staple food for centuries. But have you ever wondered how those golden kernels are transformed into the fine flour that we use in our baking and cooking? Join us on a fascinating journey through the process of maize milling, from kernel to flour, and discover the intricate steps involved in turning this humble grain into a versatile ingredient that nourishes us all.

– The Evolution of Maize Milling Techniques

Maize milling has undergone a remarkable evolution over the centuries, transforming from a basic manual process to a highly efficient and mechanized industry. The journey begins with the extraction of maize kernels from the cob, followed by a series of intricate steps that culminate in the production of fine maize flour.

One of the key advancements in maize milling techniques is the introduction of machines that streamline the process, increasing efficiency and output. From the traditional stone mill to modern roller mills, each stage of milling plays an essential role in refining the maize kernels into high-quality flour. Innovations such as degermination, sifting, and fortification have revolutionized the industry, ensuring that the final product meets the highest standards of quality and nutritional value.

- Understanding the Maize Kernel: Anatomy and Characteristics

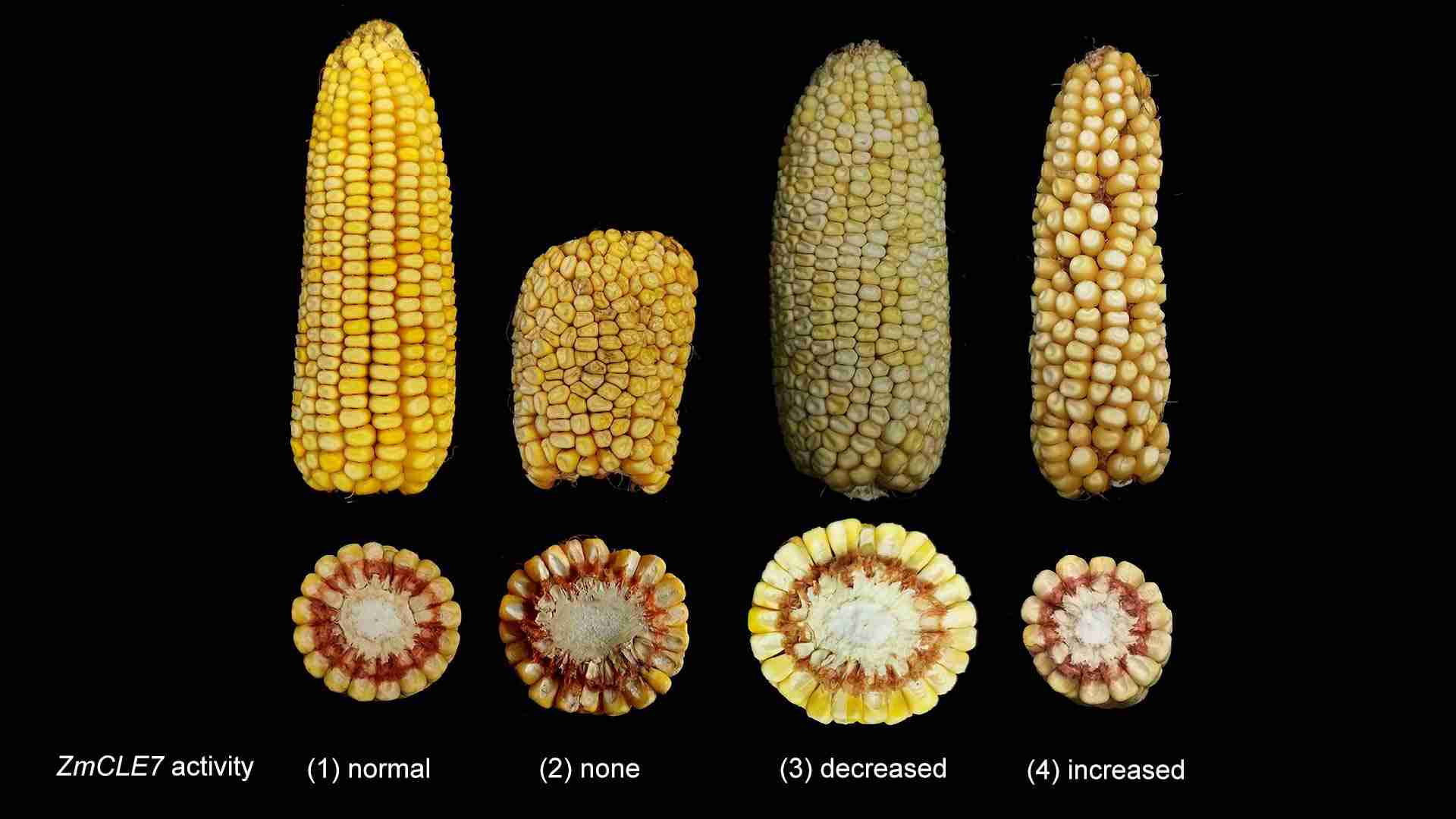

As we embark on our journey through maize milling, it is essential to delve into the intricate anatomy and characteristics of the maize kernel. The maize kernel, also known as a corn kernel, is a marvel of nature with its unique composition and structure. Each kernel consists of several distinct parts, each serving a specific function in the growth and development of the plant.

One of the key components of the maize kernel is the endosperm, which makes up the majority of the kernel and contains starch, protein, and other nutrients essential for plant growth. Surrounding the endosperm is the germ, a small but vital part of the kernel that contains essential oils, vitamins, and minerals. The outermost layer of the kernel is the protective hull, which shields the inner components from external threats.

– Key Steps in the Maize Milling Process

Maize milling is a fascinating process that transforms raw maize kernels into versatile and essential maize flour. The journey through maize milling involves several key steps that are crucial to producing high-quality flour that can be used in a variety of culinary creations.

- Cleaning: The first step in the maize milling process is cleaning the maize kernels to remove any impurities such as dust, dirt, and foreign materials.

- Conditioning: Once the maize kernels are clean, they are conditioned by adding water to soften the kernels and make them easier to mill.

- Grinding: The conditioned maize kernels are then ground into flour using a mill, which can be either a hammer mill or a roller mill.

- Sieving: After grinding, the maize flour is sieved to remove any remaining coarse particles and ensure a fine, uniform texture.

– Best Practices for Producing High-Quality Maize Flour

Embark on a journey through the fascinating world of maize milling, where kernels are transformed into high-quality flour. To ensure top-notch results, it’s essential to follow best practices every step of the way. From sourcing the finest maize to meticulous milling processes, here’s how you can produce top-tier maize flour:

- Quality Maize Selection: Start with premium maize kernels that are free from impurities and moisture. Opt for varieties known for their flavor and nutritional value.

- Proper Cleaning and Drying: Thoroughly clean maize kernels to remove any dirt or debris. Ensure proper drying to prevent mold growth and maintain optimal quality.

- State-of-the-Art Milling Equipment: Invest in high-quality milling machinery to efficiently grind maize kernels into fine flour.

- Precise Milling Process: Follow precise milling procedures to achieve the desired texture and consistency in the final maize flour product.

| Maize Milling Step | Key Points |

|---|---|

| Cleaning | Remove dirt and debris from maize kernels |

| Drying | Avoid mold growth by ensuring proper drying |

| Milling | Utilize state-of-the-art equipment for efficient grinding |

By following these best practices and paying attention to every detail, you can produce high-quality maize flour that’s a cut above the rest. Elevate your maize milling process and delight customers with the finest flour that’s perfect for a wide range of culinary creations.

The Way Forward

As we conclude our journey through maize milling, we hope you have gained a deeper understanding of the intricate process of transforming a simple kernel into the versatile flour that plays a vital role in our daily lives. From the grinding of the maize kernels to the sifting of the flour, every step is a testament to the skill and craftsmanship of those who work tirelessly to bring this essential ingredient to our tables. The next time you enjoy a warm loaf of bread or a steaming bowl of cornmeal porridge, take a moment to appreciate the journey that your food has taken to reach you, and the labor of love that goes into every bag of maize flour. Thank you for joining us on this enlightening expedition through the world of maize milling.