Nestled in the heart of a lush green landscape, an unassuming building hums with activity, its doors opening to reveal a world both familiar and foreign. Welcome to the unseen world of rice, where the intricate process of transforming golden grains from paddy fields to dinner tables unfolds. Join us on a journey inside a paddy processing factory, where the art of rice production is brought to life in a symphony of machinery and human hands. Embark on a behind-the-scenes exploration of this essential staple, where innovation meets tradition in a mesmerizing dance of efficiency and precision. Step into a realm where the ordinary becomes extraordinary, and witness firsthand the magic that happens within the walls of a rice processing facility.

Exploring the Intricate Process of Rice Milling

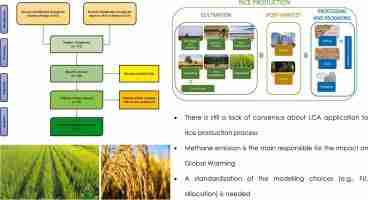

Rice milling is a fascinating process that involves a series of intricate steps to transform raw rice paddy into the polished grains that we see on our dinner tables. At a paddy processing factory, the journey of rice begins with the cleaning and soaking of the paddy, followed by the removal of the husk and bran to reveal the inner white rice kernel. This process requires precision and careful handling to ensure that each grain is processed efficiently and effectively.

As the rice progresses through the various stages of milling, it undergoes polishing to achieve its signature white appearance and undergoes quality control inspections to ensure that only the best grains make it to the final packaging stage. The entire process is a blend of modern technology and traditional methods, creating a harmonious dance of machinery and human expertise. The end result is a product that not only sustains us but also connects us to the rich heritage and culture of rice cultivation.

Unveiling the Cutting-Edge Technology Behind Paddy Processing

Rice, one of the most consumed staple foods worldwide, undergoes a fascinating journey from the paddy field to your plate. Let’s take a closer look at the cutting-edge technology that powers the paddy processing factories, revealing the intricate process behind the scenes.

Inside a modern paddy processing factory, sophisticated machinery and technology work together seamlessly to transform raw paddy into the polished rice we all recognize. The key steps in the process include cleaning, husking, polishing, and grading, each performed with precision and efficiency to ensure the highest quality rice product.

The process of paddy processing involves the following steps:

| Step | Description |

|---|---|

| Cleaning | Removing impurities such as dust, stones, and husks from the paddy. |

| Husking | Removing the outer husk to reveal the brown rice inside. |

| Polishing | Removing the bran layer to produce white rice with a shiny finish. |

| Grading | Sorting the rice based on size, shape, and quality. |

Maximizing Efficiency and Quality Control in a Paddy Processing Factory

Rice is a staple food for many cultures around the world, but have you ever wondered what happens behind the scenes at a paddy processing factory? It’s a fascinating world of efficiency and quality control, where each grain of rice is meticulously handled to ensure the highest standards are met.

At our state-of-the-art facility, we utilize the latest technology and machinery to streamline the paddy processing process. Our expert team of workers works tirelessly to ensure that each grain of rice is cleaned, dehusked, and polished to perfection. By maximizing efficiency and maintaining strict quality control measures, we are able to produce top-quality rice products that are enjoyed by people all over the world.

Best Practices for Sustainable Rice Production in Modern Processing Facilities

Rice production is a vital component of food security worldwide, with modern processing facilities playing a key role in ensuring sustainability. It’s not just about milling the grains, it’s about fostering a deep respect for the crop and the environment it grows in. Here are some best practices that modern processing facilities can adopt to promote sustainable rice production:

- Water management: Implementing efficient water usage systems to minimize waste and pollution.

- Energy efficiency: Utilizing renewable energy sources and optimizing energy usage to reduce carbon footprint.

- Waste reduction: Recycling by-products for use in other industries or converting them into value-added products.

By incorporating these best practices into their operations, paddy processing factories can not only improve the quality of their rice products but also contribute to the preservation of our environment for future generations. The unseen world of rice processing holds immense potential for positive change, and it’s up to us to harness it responsibly.

The Way Forward

As we peel back the curtain on the intricate world of rice processing, it becomes clear that there is much more to this staple food than meets the eye. From the humble paddy fields to the bustling processing factories, every step in the journey of rice is a carefully orchestrated dance of precision and efficiency. So the next time you sit down to enjoy a steaming bowl of rice, take a moment to appreciate the unseen world that brings this seemingly simple grain to your plate. The beauty of rice lies not only in its taste and texture, but in the fascinating process that transforms it from a grain in a field to a meal on your table.