From the golden fields of wheat to the crispy flakes in your morning bowl, the art of cereal processing transforms simple grains into beloved breakfast staples. Join us on a journey through the intricate process of turning raw grains into the delicious cereals we know and love. Explore the secrets behind each step, from harvesting and milling to mixing and shaping, as we delve into the fascinating world of cereal processing.

Choosing the Right Type of Grain for Cereal Processing

When it comes to cereal processing, the choice of grain plays a crucial role in the final product’s quality and taste. Different types of grains offer unique textures, flavors, and nutritional benefits, making the selection process an important step in creating the perfect bowl of cereal.

Some popular grains used in cereal processing include oats, wheat, rice, and corn. Each grain brings its own set of characteristics to the table, from the chewy texture of oats to the light and crispy consistency of rice. By carefully considering the attributes of each grain, cereal manufacturers can craft a wide variety of delicious and nutritious breakfast options for consumers to enjoy.

Enhancing Nutritional Value Through Processing Techniques

When it comes to cereal processing, a variety of techniques are used to enhance the nutritional value of grains before they make their way to your breakfast bowl. One such technique is milling, where the outer layers of the grain are removed to expose the nutrient-rich inner kernel. This process helps to increase the protein content, as well as the fiber and mineral content of the final product.

Another important processing technique is fortification, where vitamins and minerals are added to the cereal to boost its nutritional value. In addition, extrusion is a common method used to improve the digestibility of cereals, making it easier for our bodies to absorb the nutrients. By utilizing these processing techniques, cereal manufacturers are able to provide consumers with a product that not only tastes great but also packs a powerful nutritional punch.

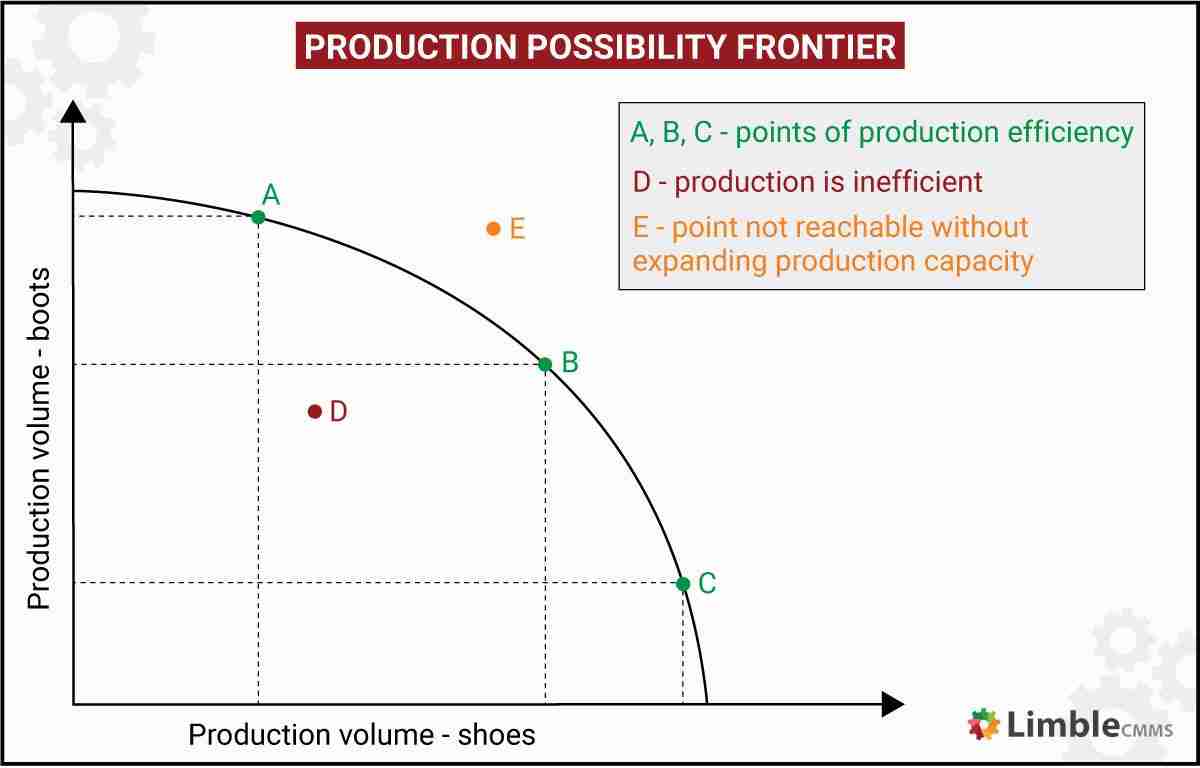

Optimizing Production Efficiency in Cereal Processing

When it comes to , every step of the process matters. From sourcing the finest grains to ensuring the perfect blend of ingredients, the art of cereal processing is a delicate balance of science and creativity. By utilizing the latest technology and industry best practices, cereal manufacturers can streamline their production process and deliver high-quality products to consumers.

One key aspect of optimizing production efficiency is maximizing the use of resources. By carefully monitoring inventory levels, production schedules, and equipment performance, manufacturers can minimize waste and downtime. Implementing **automation** and **quality control measures** can also help ensure consistency in product quality and reduce the risk of errors. With a focus on continuous improvement and innovation, cereal processing companies can stay ahead of the competition and meet the ever-evolving demands of the market.

Innovative Packaging Solutions for Freshness and Longevity

When it comes to ensuring that cereal stays fresh and crunchy from the moment it is processed to the bowl on the breakfast table, innovative packaging solutions play a crucial role. By utilizing cutting-edge technology and materials, companies can extend the longevity of their products while maintaining their quality and taste. One such solution is the use of resealable bags, which not only keep the cereal fresh but also make it convenient for consumers to enjoy multiple servings without worrying about spoilage.

Another innovative packaging solution that has gained popularity in recent years is vacuum-sealed bags. By removing the air from the packaging, these bags help preserve the freshness of the cereal and prevent it from becoming stale. Additionally, some companies have started using eco-friendly packaging materials, such as compostable bags made from plant-based materials, to not only reduce their environmental impact but also appeal to consumers who are becoming increasingly conscious of sustainability issues. By continuously evolving and adapting their packaging solutions, cereal companies can ensure that their products remain fresh and delicious for as long as possible.

To Wrap It Up

As we conclude our exploration of the intricate and fascinating world of cereal processing, we are reminded of the incredible journey that grains undergo to make it to our breakfast bowls each morning. From the fields where they are grown to the mills where they are transformed, the art of cereal processing is a testament to human ingenuity and centuries of tradition.

Next time you pour yourself a bowl of cereal, take a moment to appreciate the complexity and skill that goes into every delicious bite. And remember, behind every spoonful of cereal lies a story of craftsmanship, dedication, and passion. So savor that next bowl of crunchy goodness, knowing that it is the result of a truly remarkable process that begins with a simple grain.